INFICON 新闻

了解更多关于我们的产品和服务

Related information

product

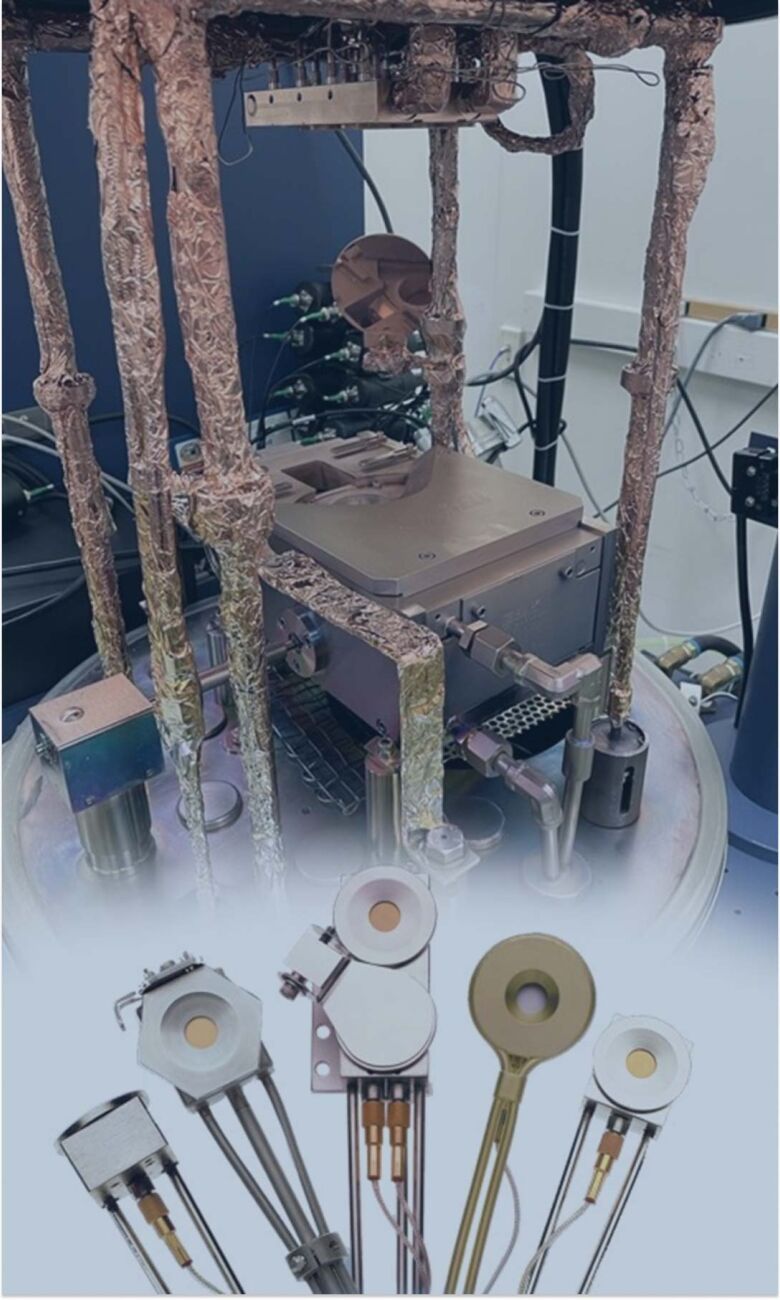

石英监控器晶体

INFICON 晶体 100% 通过精度和可靠性测试

product

1 inch (25.4MM) 研究晶体

在严苛的应用中达到最高的稳定性

product

IMM-100

采用ModeLock技术构建的紧凑型沉积监测器,以最高的厚度精度、最佳的测量分辨率和最低的速率噪声,最大限度地提高再现性和均匀性

product

IMM-200

采用ModeLock技术构建的紧凑型沉积监测器,以最高的厚度精度、最佳的测量分辨率和最低的速率噪声,最大限度地提高再现性和均匀性

product

SemiQCM® SR 用于半导体工艺监测的传感器

SemiQCM™ SR 传感器是前驱体监控系统的一个组件,其他组件包括 IMM-200 和 FabGuard(版本 19.12.00-a 或更高。

product

SemiQCM® CR 用于半导体工艺监测的传感器

实时、现场工艺监控,防止过度蚀刻,确定腔室清洁终点

news

4月发现使用镁敏感的OLED晶体的好处

稳定性增强,厚度精度提高,节省时间