Learn more about our products and services.

Related information

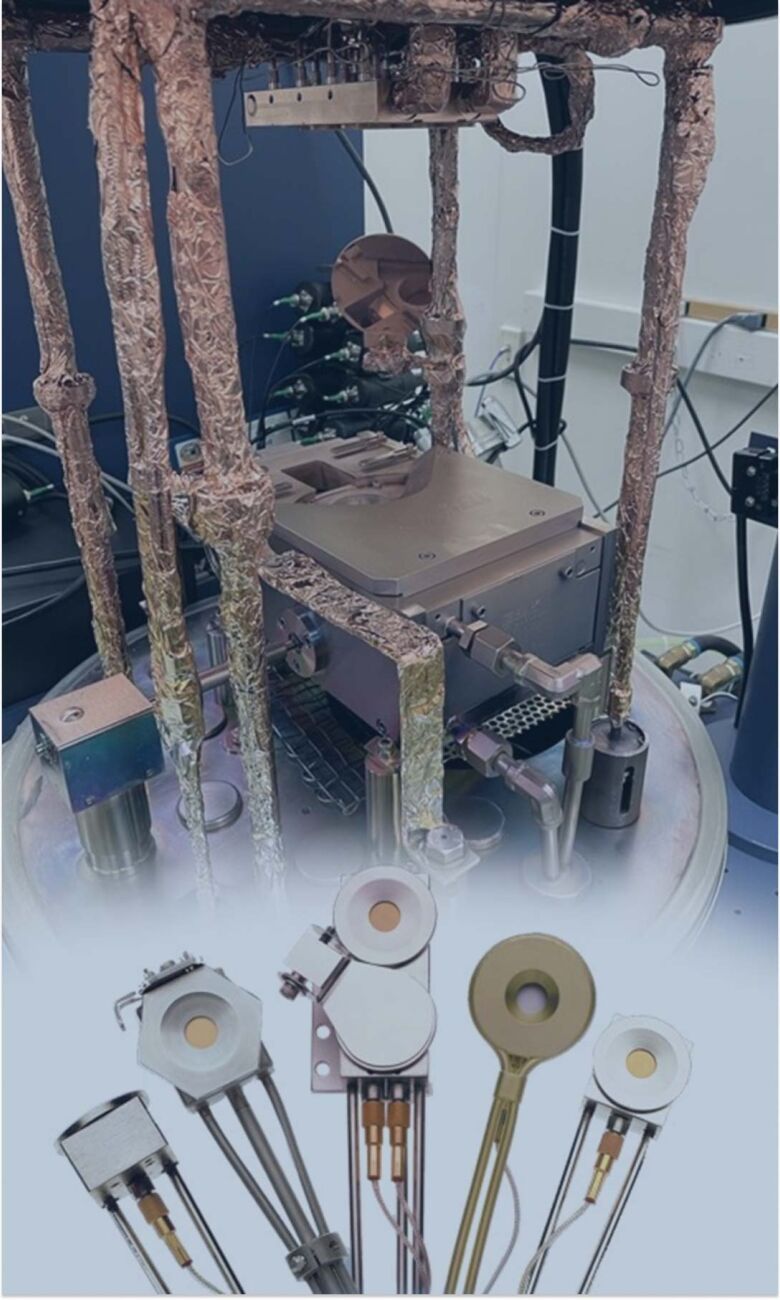

100% Tested for Accuracy and Reliability and needed to monitor deposition rate in situ, collect accurate measurement data, optimize PVD applications, and to automate the process when coupled with a thin film controller.

Quartz crystals are needed to monitor deposition rate in situ, collect accurate measurement data, and provide a means to analyze research applications.

Compact deposition monitor built with ModeLock technology to maximize reproducibility and uniformity with the highest thickness accuracy, best measurement resolution, and lowest rate noise

Compact deposition monitor built with ModeLock technology to maximize reproducibility and uniformity with the highest thickness accuracy, best measurement resolution, and lowest rate noise

SemiQCM™ SR sensor is one component of a system for precursor monitoring with the other components being an IMM-200 and FabGuard (version 19.12.00-a or higher).

Real-Time, in situ process monitoring, prevent over-etching, identify chamber clean end point

Increased stability, better thickness accuracy and time saved