A Story of Success:

Ensuring Coffee Freshness with Contura® Series Leak Detectors

From Challenge to Solution: Bialetti's Journey with INFICON

In the coffee industry, where quality and consistency are essential, Bialetti faced a significant challenge. Their mission was to ensure every single coffee capsule and soft pack met high standards of freshness, flavor, and aroma. With increasing demands for longer shelf life and stringent environmental standards, Bialetti turned to INFICON for a solution that would meet these expectations.

A Partnership Built on Expertise

INFICON's extensive expertise in the food and packaging industry made it a reliable partner for Bialetti. This collaboration was based on mutual respect and a shared commitment to quality. Bialetti, a well-known Italian coffee manufacturer, required a robust and innovative approach to leak detection in their packaging process. They found this in the Contura® series.

Improving Quality Assurance

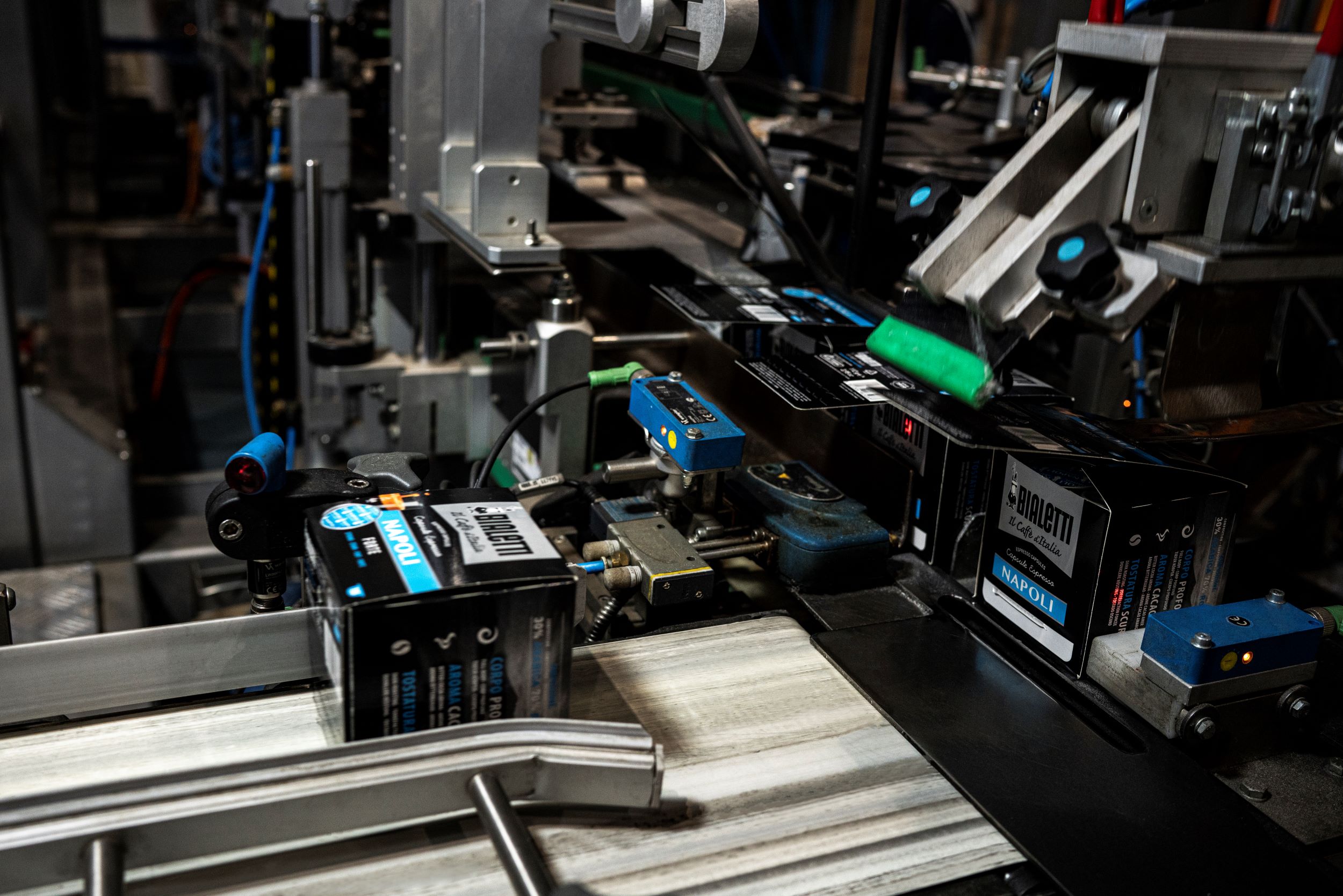

Bialetti’s Operations Manager, Arman Khazali, recalls the decision to transition from traditional destructive testing methods to a non-destructive approach. The Contura® S400 series, with its pressure increase method, became an integral part of their production line. This decision was driven by the need for precision and efficiency, ensuring that each coffee capsule delivered a consistent brew.

Demonstration of the Leak Detection Process with Contura S400

The video below illustrates how the Contura S400 leak detector is utilized to safeguard the freshness and integrity of Bialetti's coffee packaging.

The Impact of Technology

The results were notable. Bialetti’s production saw improvements in quality control, waste reduction, and efficiency. The Contura® S system’s ability to detect small leaks without damaging the packaging enhanced their testing process. With 180 million coffee capsules and 2.9 million soft packs produced annually, maintaining integrity during the brewing process was crucial. INFICON’s technology helped ensure that each product met Bialetti’s standards.

A Testimony to Excellence

Khazali highlights the benefits of using the Contura Seal Tester, emphasizing its user-friendly touch display and acoustic signals that have streamlined operations.

Looking Ahead

The partnership with INFICON has enhanced Bialetti’s production capabilities and opened doors to future collaborations. The synergy between the two companies suggests potential for further innovations and improvements. Khazali sees a future where Bialetti continues to expand, supported by the reliable technology from INFICON.

Bialetti's Heritage and Partnership with INFICON

Christoph Heinz Huber, Agents & Account Manager at INFICON, adds

Embracing Sustainability

The switch to non-destructive testing aligns with Bialetti’s commitment to sustainability. By reducing waste and ensuring that only properly sealed products reach consumers, they contribute to a more environmentally friendly production process. This commitment aligns with their values and the expectations of their customers.

The cooperation between Bialetti and INFICON demonstrates the benefits of combining innovation with dedication. It’s a story of meeting challenges, adopting new technologies, and setting standards in the industry. Bialetti continues to deliver quality coffee experiences with the support of INFICON, ensuring each cup meets their high standards.