Easily Determine the Total Leak Rate with One Push of a Button

Understanding the I-Guide Feature in Sensistor® Sentrac® Hydrogen Leak Detector

In industrial manufacturing, rigorous leak testing is essential to ensure the safety, performance, and longevity of components. Some components have multiple potential leak points, all of which must be accurately tested during production. Testing for multiple leaks is especially critical in industries such as automotive, aerospace and HVAC/R, where any small leak can significantly impact the reliability of the entire system. Multiple leaks on a single component can lead to incorrect "accept or reject" decisions, significant operational failures and costly recalls. By ensuring that the correct number of locations on each test part is tested for leaks, and that each location is tested for the required minimum time, product quality is improved and the risk of operator error is reduced.

I-Guide ensures that each measurement is accurately captured and summed

Equipment versatility is key in leak testing, as different components may have different leak points and leak limits. In the case of parts with multiple leak points, the total leak size is often critical in determining whether the test part passes the quality test or not.

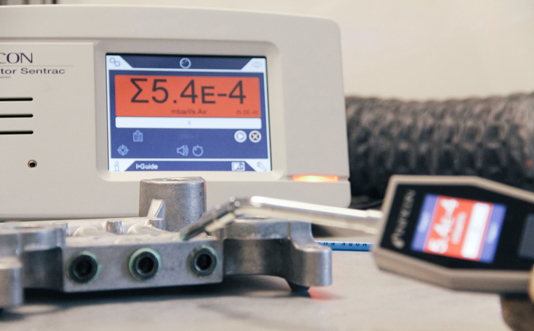

The new Sensistor® Sentrac® Hydrogen Leak Detector software version (V5.01) includes the I-Guide feature. I-Guide allows operators to measure multiple leaks and automatically sum the total to match the total leak rate defined for the part.

Per Jennéus, Product Manager at INFICON AB with twenty years’ experience in leak detection equipment, explains that “The Sentrac leak detector is designed to handle multiple leak points without compromising accuracy. I-Guide logs each single measurement and adds them up to provide the total leak rate.” This thorough approach ensures that no leak is missed, and the overall integrity of the system being tested is accurately assessed. “To start or stop a measurement, the user simply presses the probe button at each individual leak position."

The number of points can be pre-set or user-defined, up to 25 measurement points. A pre-set number of measurements can be ideal for users testing identical parts, while a dynamic number of measurements is more suitable for users with a diverse range of parts to test” says Jennéus. The user can choose to have Sentrac give an alarm when a test point exceeds the alarm limit or when the sum of all the leaks does so. This adaptability ensures that I-Guide can be used effectively on a wide range of components, from simple to complex systems. “The sum is then compared to a predefined Reject Level. If the sum of all leaks is equal or exceeds this level, the device shows "REJECT" and if it's below the reject level, "ACCEPT" is displayed," explains Jennéus.

Advantages of using I-Guide

The primary advantages of using I-Guide for multiple leak measurements are accuracy, efficiency, and ease of use. By automatically summing the leak rates, I-Guide eliminates the potential for human error enabling even inexperienced operators to find all leaks. This saves time and ensures that the measurements are consistent and reliable. Additionally, the clear "ACCEPT" or "REJECT" outcome simplifies decision-making for the operator, making the testing process more straightforward and reducing the risk of overlooking critical leaks.

Complete operator guidance

The I-Guide feature is already integrated in the Protec P3000 Helium Leak Detector and the Ecotec® E3000 Multigas Leak Detector, for a complete operator guidance. By simply defining the leak positions to be checked, time sequences and repetition rates, you ensure even the most inexperienced operator can efficiently detect leaks.

Curious about how to use I-Guide?

If you want to know more about the I-Guide and how it can guide the user during leak testing, contact our leak detection experts!

Are you ready to integrate your production quality monitoring?

Thanks to the I-Guide and BM1000, you can now integrate Sentrac in a leak detection system and log each single leak value on every test object. Read more about Sentrac and BM1000 for seamless automation integration!