Ensuring Safety in a Hydrogen Future

EX-certified instruments for safe leak detection

Production, storage and use of hydrogen as a way to decarbonize the gas industry and other sectors is a topic of rapidly growing interest worldwide. Whether hydrogen is used as fuel in a car or as an energy carrier in the existing gas infrastructure, safe usage of hydrogen gas will require new methods and procedures. One of these is leak detection.

Leak detection equipment for use in potentially hazardous locations has been used by the gas and petrochemical industry for decades. These instruments typically use a form of explosion protection called intrinsic safety, which means that the instrument circuitry is designed to prevent any ignition, even in the event of equipment malfunction.

Depending on the target gas, vapor or liquid, an instrument would require different classification to fulfill the same level of safety under the same environmental conditions. The classification of an instrument must always be readable on the instrument label according to the standard.

For example, for leak detection in an environment where methane (CH4) is expected occasionally during normal operation it would be enough using a detector with ATEX rating of Gas Group IIA and Equipment Protection Level (EPL) Gb, which is suitable for Zones 1 and 2. This corresponds to Gas Group D in the division system used in the US.

This would be different for hydrogen and natural gas blends.

Make sure you operate a safe instrument in a hydrogen future

Hydrogen has two important properties that are significantly different from methane, the first is the minimum ignition energy (16 times lower) and the second is the range were a concentration is flammable (almost 6 times wider). This makes hydrogen easier to ignite by a spark and it is more likely that a flammable concentration exists.

ISO 80079-20-1 states that a blend containing over 25 Vol% H2 would require an ATEX rating of at least gas group IIB. The standard gives no clear indication of limit when the mixture is to be classified in gas group IIC. Recent studies indicate, however, that the IIC limit should be in the range of 70-75% and also that the IIB limit may need to be lowered.

This fact will add complexity to the gas companies instrument management and the standard operating procedures.

Depending on the mixing conditions in the grid, some instruments may be prohibited from being used for the intended work due to an inappropriate ATEX rating. If some instruments are prohibited to be used in some parts of the grid due to a wrong ATEX rating, the risk of an accident due to human error would increase. Purchasing equipment with an ATEX rating that fulfills the tougher requirements in a hydrogen future is the safe and easy way to reduce the complexity of the internal procedures and assure safety.

Are you looking for Ex-certified alternatives for leak detection?

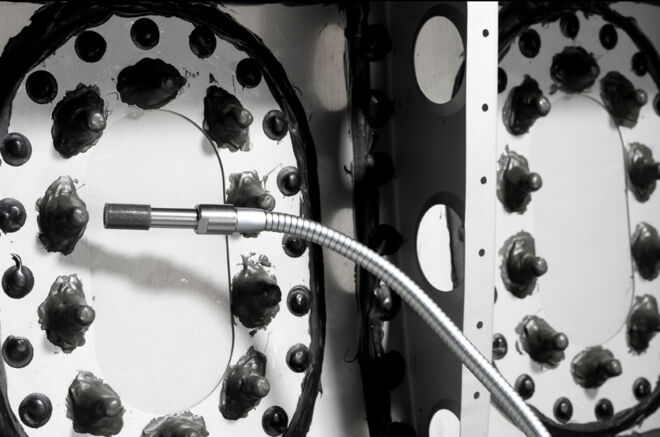

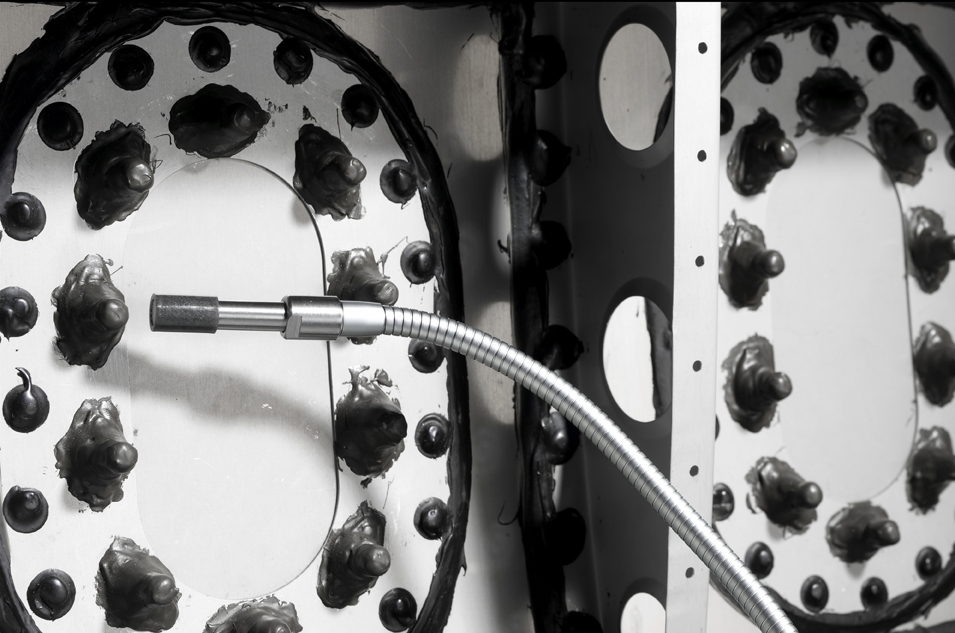

Both the IRwin® Methane Leak Detector and the Extrima® Hydrogen Leak Detector from INFICON have been designed to fulfill the highest levels of safety. They are intrinsically safe and meet the highest ATEX requirements of Zone 0 and IIC (Div system: Class I, Div 1, Groups B, C and D). This means that they are safe to use in an environment where an explosive gas atmosphere is present continuously, for long periods or frequently. They are also allowed for use in an environment where 100% hydrogen could be expected, such as a hydrogen injection point into the grid or a hydrogen storage tank. This means that both instruments can be used for all foreseen applications without restrictions on methane and/or hydrogen blends.

The proprietary sensor technologies in both IRwin and Extrima are not cross sensitive to the mixing ratio of methane and hydrogen which makes them reliable and applicable under all conditions.