FabTime Used as an Investigative Tool in the Factory

FabTime® is a flexible reporting application that plays a vital role in factories. It provides a standardized system for factory personnel across diverse teams to efficiently monitor KPIs, identify opportunities for improvement, and quickly answer questions about factory operations.

FabTime differentiates itself from other reporting applications by saving teams hours of time identifying the root causes of issues. Using FabTime, factory personnel can configure reports to visualize the information they need and independently identify the source of problems without involving IT. With 175 industry-specific reports to choose from, and versatile configuration functionalities like drill down, filtering and more, users can pinpoint the causes of problem within minutes, allowing teams to respond sooner and devote more time on improvements.

Use Case

A process engineer informed the IE manager that a particular set of 5X tools were equally qualified to run all recipes. However, the IE manager wants to independently verify the accuracy of this statement before making any decisions involving these tools. The IE turns to FabTime to quickly obtain an answer.

Within FabTime, the IE has a range of options to verify if the tools are qualified to run all recipes. They can search for a relevant report and customize it to display the necessary information. Alternatively, if they have a pre-existing report that they consistently use, it can be readily accessed from one of their dashboards, streamlining the verification process.

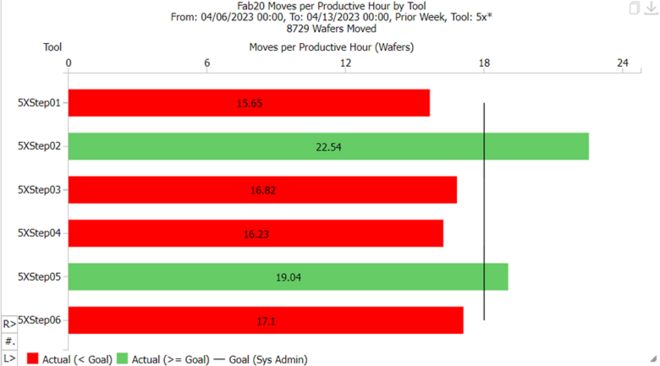

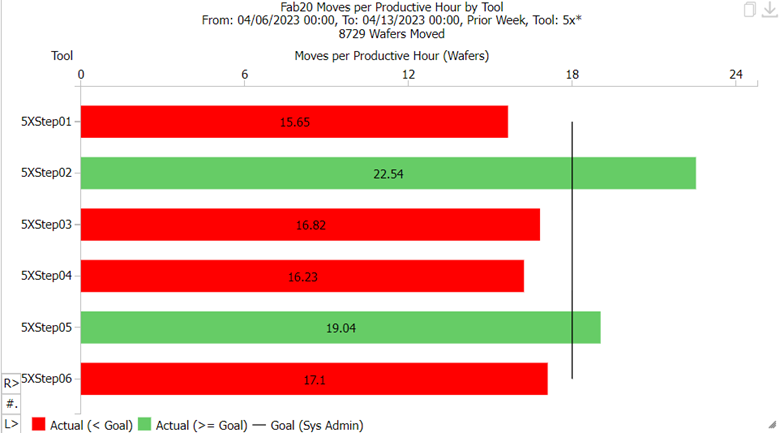

For this case, the IE might utilize the report Moves per Productive Hour by Tool. Upon review, the IE identified tool 5XStep02 as the clear leader among the tools, exhibiting a higher number of wafer moves per hour. This disparity may lead the IE to think the tools are not, in fact, equally qualified.

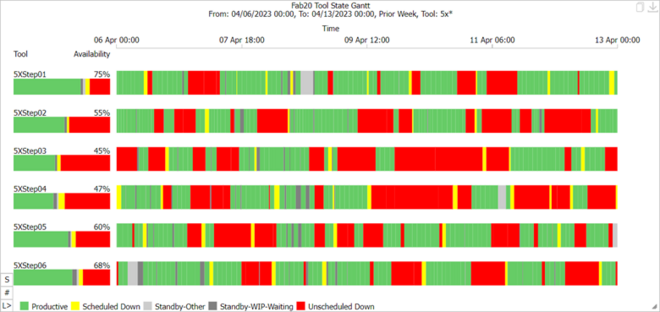

To further scrutinize the production disparity between the tools, the IE manager may use a Tool State Gantt Chart. This chart illustrates elapsed time by tools for each tool-state transaction. After filtering for the 5X tool and applying the appropriate time period, analysis of this chart would reveal that despite 5XStep01 displaying greater availability than 5XStep02, the latter still demonstrated more moves per productive hour.

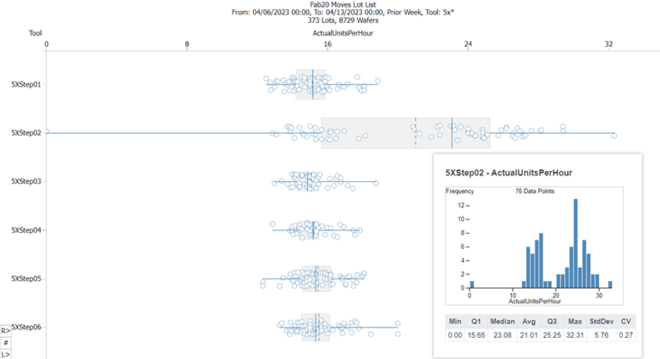

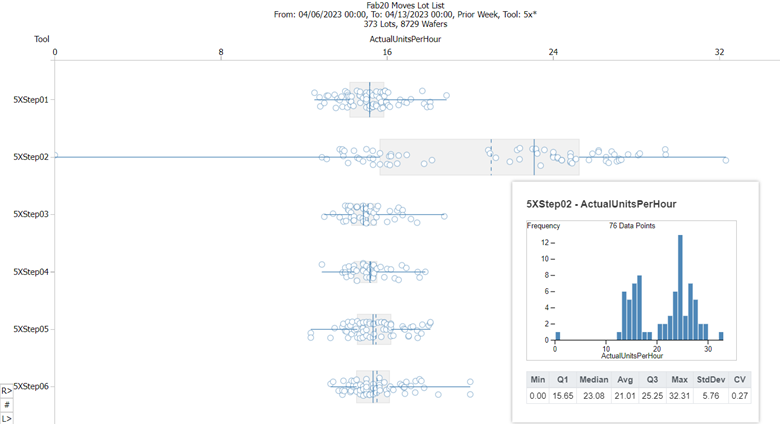

To further investigate this 5X set of tools, the IE may move onto a Moves Lot List chart. This chart visualizes the spread of moves per hour across the tools. For immediate transparency into the data distribution, the IE may convert this chart into a boxplot, which is as simple as a few clicks in FabTime. FabTime boxplots also include histograms, which, in this case reveals to the IE a bi-modal distribution on 5XStep02, or in simpler terms, indicates two prominent groups (the two peaks in the histogram) in the data. Unlike 5XStep01 that clustered around 16 units per hour (UPH), the distribution for 5XStep02 fluctuates.

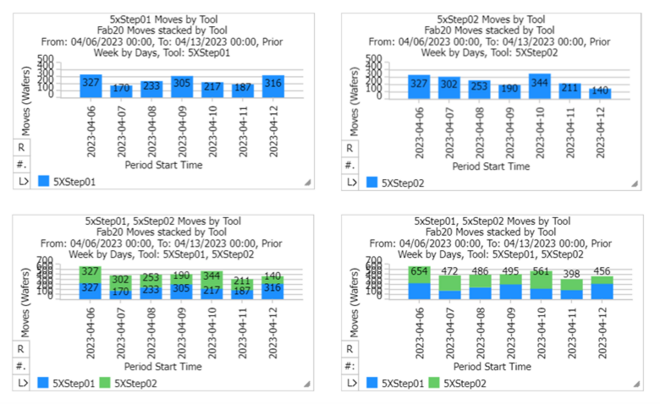

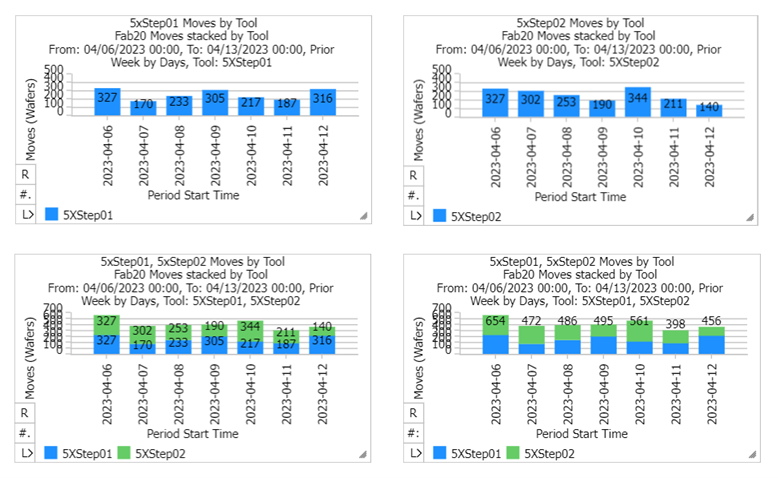

After analyzing these reports, the IE can confidently confirm that this set of 5X tools is not equally qualified to run all recipes. Even one report would have been sufficient to draw this conclusion, but building and analyzing these reports only required a few minutes of the IE’s time and further strengthens the conclusion. There are even more ways the IE could have explored this issue deeper, such as by creating sparkline charts to compare the daily moves of different steppers side-by-side.

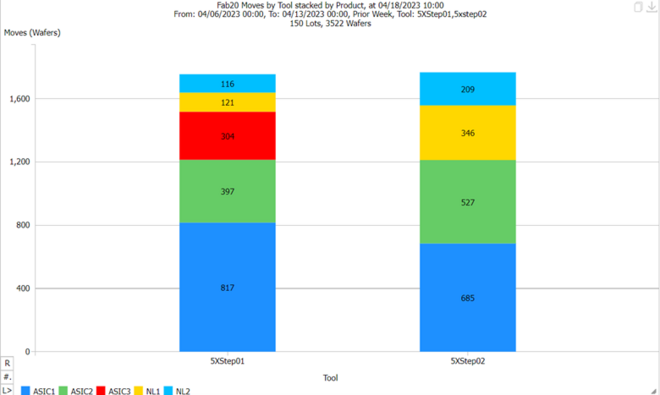

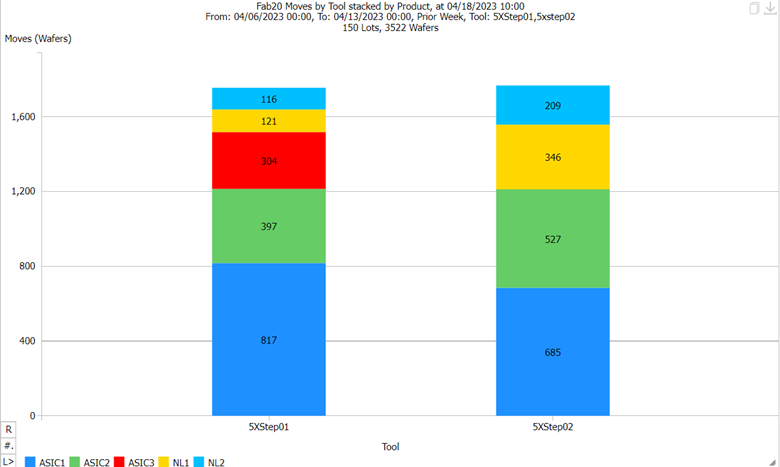

Furthermore, once the IE has drawn a conclusion about the 5X tools, the IE can subsequently use FabTime to address the follow-up question of why 5XStep02 is running faster than the others. Using a Stacked Pareto Chart, the IE can compare the moves for 5XStep01 and 5XStep02 by the product to explain the disparity. The chart reveals to the IE that the tools were not running the same set of products, with the glaring red portion of the chart indicating that 5XStep01 ran all of product ASIC3.

With FabTime, the IE swiftly determined that the tools assumed to be equally qualified were not running the same recipes. Additionally, further analysis of 5XStep02 showed it was not running a product present in another tools. After this analysis, the IE can return to process engineering and equipment engineering to discuss these findings. It is possible there is a soft or hard restriction that process engineering implemented but forgot to back out. Without FabTime, such discrepancies could have gone unnoticed or required extensive manual effort from multiple employees to draw the same conclusion.

Want to Learn More About our Products and Applications?

Our newsletter offers regular updates on our latest products, applications, upcoming events, and other interesting news.