Factory Scheduler for Backend Manufacturing

Factory Scheduler Overview

In the early days of semiconductor manufacturing, "scheduling" meant teams of people poring over lot lists and routes discussing how to run WIP for the day. As factories grew in size, such an approach became impractical, necessitating technological help. Initially, home built simple dispatch lists were used, and then enhanced dispatch with critical ratio, etc. followed by tool centric rule-based dispatch. The state-of-the-art approach today uses fab-wide optimized scheduling. The Factory Scheduler uses advanced algorithms to generate a schedule based on current factory conditions and priorities. The schedule automatically updates to respond to the dynamic conditions in the factory.

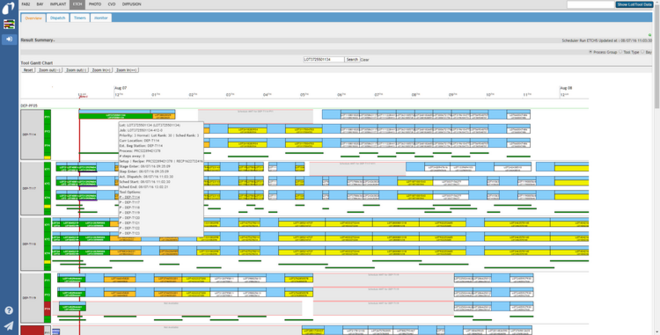

Front-end Factory Scheduler

A front-end factory is extremely complex. Wafers entering a front-end factory will complete all process steps in approximately 45 – 60 days. Because of the speed and volume of process completions, the refresh rates of the full scheduler need to be minimized. Instead of performing a forecast on the entire process flow, the schedulers perform a 12 hour forecast in a couple of minutes. An example of a typical front-end factory flow is shown here.

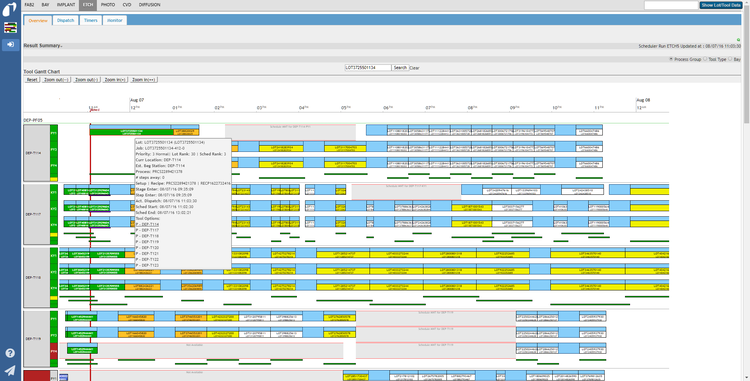

Back-end Factory Scheduler

A back-end factory is not as complex when compared to a front-end factory. Wafers entering a back-end factory will complete all process steps in approximately 7 – 10 days. This allowed INFICON to utilize its scheduler to account for the entire back-end process flow. A WIP forecast is generated from start to finish for all steps on each back-end scheduler run. An example of a typical back-end factory flow is shown below.

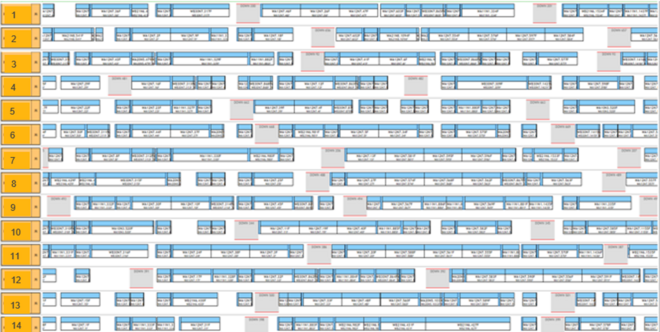

Back-end Enhancement 1: Loading Plan with Modeled Constraints

With the Factory Scheduler accommodating full end-to-end scheduling, INFICON provides an enhancement is to the scheduler enabling the facilities planning team to utilize it as a forecasting tool. In order to do this, INFICON created a method for the facilities team to enter their modeled factory constraints, for example down % by equipment type, and generate a 4 week schedule based on those constraints. This loading plan is displayed lot by lot for a 28 day period, which is something no other Enterprise Resource Planning (ERP) system can easily generate.

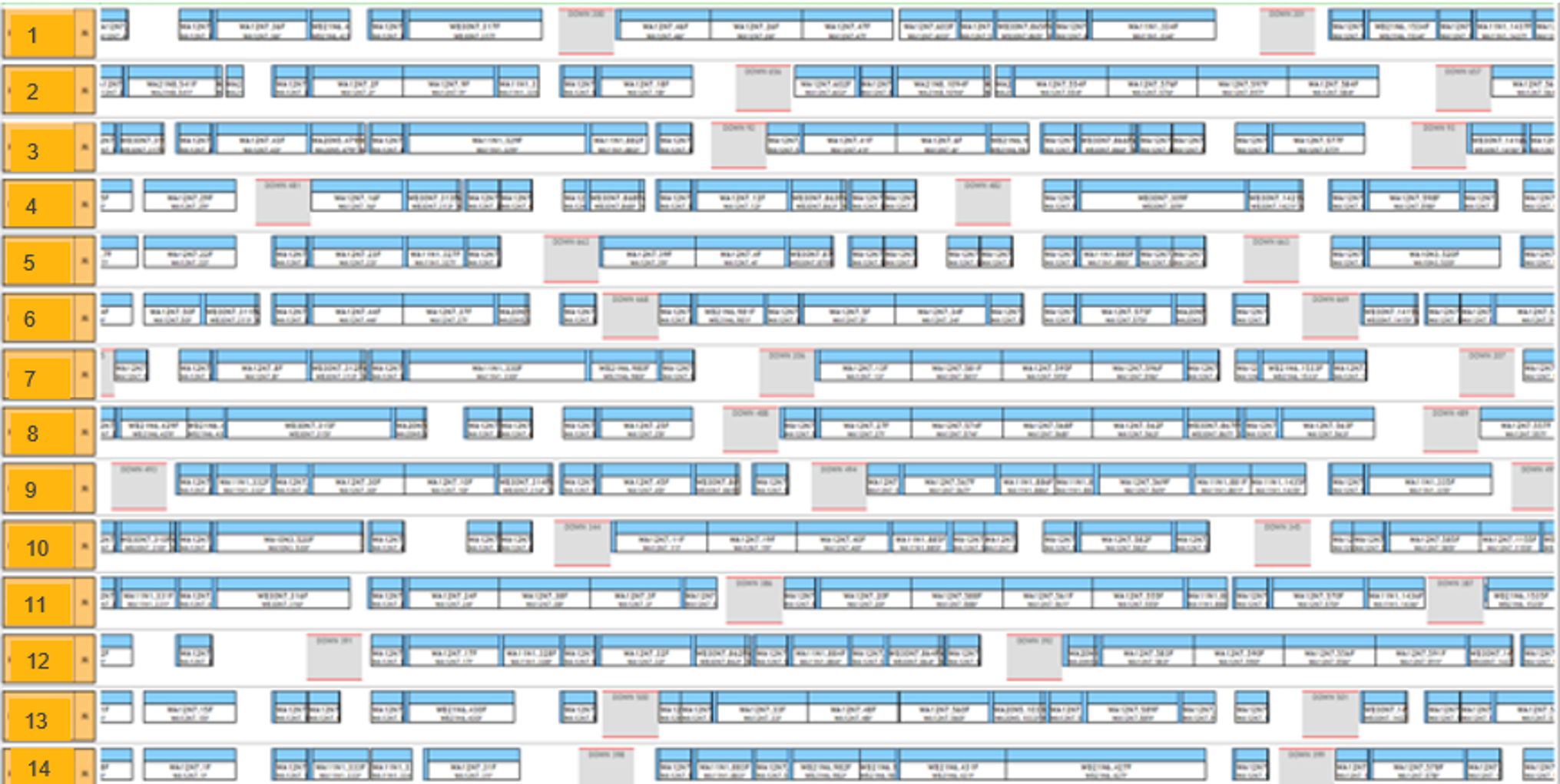

Back-End Enhancement 2: Execution of Loading Plan with NextMove

With the fully constrained schedule is generated, the next step in the project is to execute to the desired 4 week plan. This requires implementation of the NextMove application. During the rollout of NextMove, several pieces of test equipment had occurrences of an interlock violation or 'production halt.' Production halts happen when the tool is in a productive state but is not actually processing wafers. Since these events can be easily identified and displayed within NextMove using a 'STOP' icon, loss times are minimized for these tools.

Summary

The combination of using Factory Scheduler with NextMove reduces cycle time, reduces inventory, improves starts plans and forecasting, and increases the capacity of bottleneck tools within semiconductor back-end operations.