Why leak testing of air conditioning systems in electric vehicles is so important

If the air conditioning fails, the EV stops

The failure of an air conditioning system in a car is frustrating and can lead to high costs. However, in electric vehicles, the air conditioning system plays a crucial role: it not only cools the interior but also the battery. A failure of the battery cooling system leads to the automatic shutdown of the battery to prevent overheating and possible fires. Therefore, careful leak testing during manufacturing is essential for the reliable operation of an electric vehicle.

Safety Mechanisms and Costs

Safety mechanisms shut down the battery in case of overheating. A leak in the air conditioning system and the associated loss of refrigerant not only causes the complete stoppage of the vehicle, but the new generation refrigerants used (e.g., HFO-1234yf) also incur significantly higher costs.

Helium Vacuum Method for Pre-testing

Pre-testing of cooling system components, such as evaporators, condensers, and air conditioning hoses, is often performed with helium as a test gas in vacuum chambers. This method is fast and precise, and with devices like the LDS3000 leak detector, even the smallest leaks can be detected. The goal is to limit refrigerant loss to 1 to 2 grams per year.

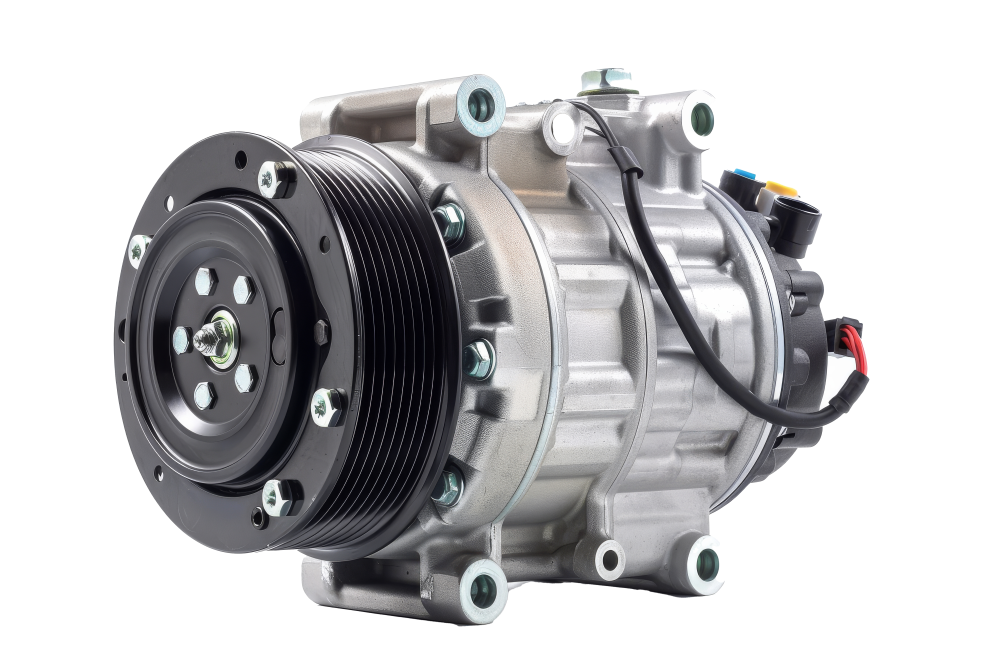

Sniffer Leak Detection for Compressors

The air conditioning compressor is not tested in the vacuum chamber but with sniffer leak detection. Often, the XL3000flex with helium or forming gas is used to detect leaks, either manually or in robotic systems.

End-of-line Testing after Installation in the Vehicle

After installing the air conditioning system, approximately six to eight connection points must be tested to avoid costly refrigerant loss. During the filling of the air conditioning system, a pressure rise test is often performed to identify gross leaks. However, small leaks can only be detected with more precise methods such as sniffer leak detection. Pressure tests are far from sensitive enough to limit refrigerant loss to 1-2 g/a. For the final leak test, the actual refrigerant is used. The Ecotec E3000 multi-gas leak detector can detect various refrigerants and has a detection limit of about 0.05 grams of refrigerant loss per year.

Leak Testing in Workshops

Testing the air conditioning system is not only essential during production but also crucial in service cases. Mobile, easy-to-use devices for use in workshops, such as the AST300 device, can quickly and reliably detect leaks during repairs

Conclusion: Quality assurance is crucial

In electric vehicles, the air conditioning system is not just a comfort feature but essential for operational safety. Leak testing at all manufacturing stages – from pre-testing components to assembly and end-of-line tests – is indispensable. This is the only way to avoid expensive repairs and dangerous failures.

Side Note: Leak Testing in the Water-Glycol Circuit

The cooling of the traction battery using a water-glycol circuit must also be permanently leak-proof. Leaks in the water-glycol circuit pose the risk of short circuits and are therefore tested against strict standards for leak rates in the range of 10-3 to 10-4 mbar·l/s. Testing methods such as the helium vacuum method or accumulation testing are used to reliably and repeatably detect leaks of this size.

Leak Testing in the Automotive Industry

Do not miss our free e-book on "Leak Testing in the Automotive Industry"!

This free e-book covers all aspects of leak testing in the automotive industry. It provides the information you need to make decisions about the best leak testing method for your particular application and helps you avoid typical pitfalls.