Hydrogen Innovation in Motorsport

How INFICON Advanced Leak Detection for Hydrogen Mobility

Pioneering Hydrogen Technology for High-Performance Applications

Hydrogen is widely regarded as a key element in the transition to sustainable mobility. While fuel cell technology has gained traction in various applications, hydrogen combustion engines offer an alternative pathway to reducing carbon emissions - one that leverages existing engine architectures with minimal modifications. This concept was demonstrated when a pioneering hybrid hydrogen combustion drivetrain was successfully integrated into an Aston Martin Rapide S, proving that high performance and low emissions can go hand in hand.

A critical challenge in making hydrogen propulsion viable is ensuring absolute leak tightness. Hydrogen, as the smallest and lightest molecule, can escape through microscopic gaps that conventional fuels would never breach. To overcome this, industry experts turned to us, as a global leader in leak detection technology, to develop a highly precise hydrogen leak detection process. This collaboration set new standards in safety and efficiency for hydrogen-powered vehicles, proving that hydrogen combustion is not just a theoretical solution - it is ready for real-world applications.

Hydrogen Combustion: A New Approach to Sustainable Performance

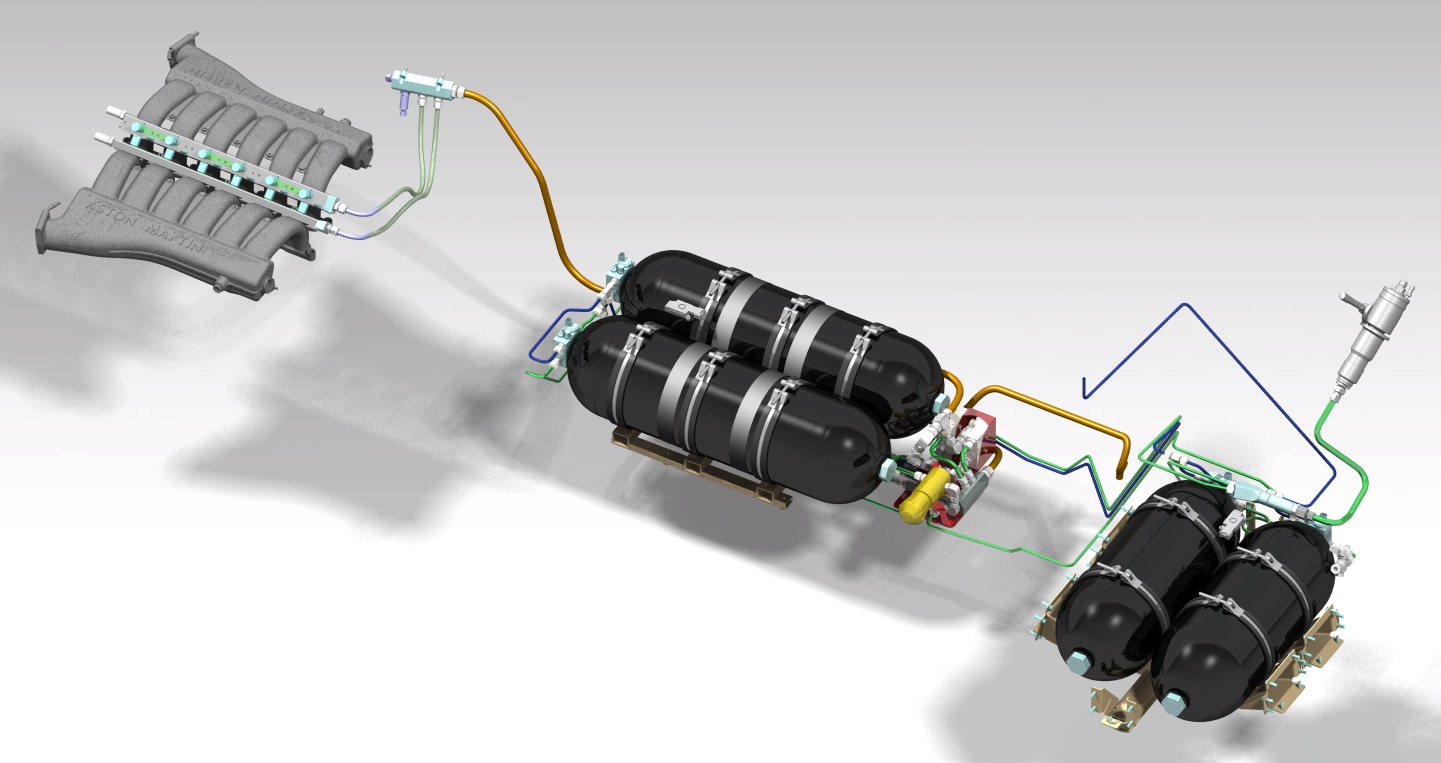

The hybrid system was designed for seamless operation on gasoline, hydrogen, or a combination of both. Featuring four high-pressure hydrogen storage cylinders, an advanced fuel injection system, and a dual-mode control unit, the technology enabled the engine - in hydrogen mode - to produce near-zero carbon emissions while still delivering exceptional performance.

One of the system’s key advantages is its adaptability. Unlike fuel cells, which require entirely new vehicle architectures, hydrogen combustion engines can be implemented with relatively minor modifications to conventional internal combustion engines. This flexibility opens the door to a faster transition to hydrogen-powered mobility, particularly in performance and heavy-duty applications where immediate high-power output is critical.

Ensuring Leak Tightness: The Role of INFICON Technology

For hydrogen propulsion to be both safe and efficient, every component must be tested to the highest standards of leak tightness. Hydrogen’s low molecular weight and high diffusivity make containment particularly challenging, necessitating advanced leak detection solutions.

INFICON provided state-of-the-art hydrogen leak detection technology to ensure system integrity. During the initial development and testing phases, the Sensistor ISH2000C - the predecessor of the Sensistor Sentrac - played a crucial role in verifying the leak tightness of all high-pressure components. The leak detection process involved pressurizing hydrogen-carrying components with a forming gas mixture (5% hydrogen, 95% nitrogen) and using INFICON sensors to detect any escaping gas. This method is far more precise than traditional water bath or spray test techniques and allows for rapid identification and quantification of leaks.

Proven in Extreme Conditions

To validate the robustness of hydrogen propulsion, the hybrid hydrogen-powered Aston Martin Rapide S was put to the ultimate test in high-performance motorsport conditions. During endurance racing, the system demonstrated its real-world viability. INFICON’s mobile leak detection solutions ensured the safety and reliability of the hydrogen system throughout these tests. The Sensistor ISH2000C was deployed for trackside inspections, enabling engineers to check hydrogen components before and after each race session. Its rapid response time allowed for precise adjustments, minimizing risks under extreme conditions.

Advancing Hydrogen Leak Detection: From the Sensistor ISH2000C to the Sensistor Sentrac

Following the successful deployment of the Sensistor ISH2000C, INFICON introduced the Sensistor Sentrac, its direct successor. The Sensistor Sentrac builds upon the proven performance of its predecessor while delivering even greater sensitivity, speed, and usability. Its advantages include:

- Higher sensitivity to detect even the smallest hydrogen leaks

- Faster response times for quicker inspections

- Advanced digital interfaces for improved data collection and analysis

- Enhanced durability for both laboratory and field use

Today, hydrogen pioneers across various sectors rely on the Sensistor Sentrac to ensure the integrity of hydrogen systems in automotive development, industrial applications, and motorsport. The evolution from the Sensistor ISH2000C to the Sensistor Sentrac highlights the rapid progress in hydrogen leak detection technology, meeting the growing demands of hydrogen-powered mobility.

A Step Toward Commercial Hydrogen Adoption

The successful implementation of hydrogen combustion technology in a high-performance environment proves that the transition to hydrogen mobility need not wait for widespread fuel cell adoption. Hydrogen combustion engines offer an immediate solution that can integrate with existing manufacturing processes while delivering significant emissions reductions.

INFICON continues to play a crucial role in enabling this transition by providing cutting-edge leak detection solutions for hydrogen applications across the automotive industry. As hydrogen-powered vehicles gain momentum, ensuring safety and efficiency through precise leak testing remains a top priority.

As the industry moves toward a more sustainable future, INFICON’s innovations in hydrogen leak detection - demonstrated by the progression from the Sensistor ISH2000C to the Sensistor Sentrac - are a clear testament to what can be achieved when innovation meets precision engineering. Whether in motorsport, industrial applications, or mass production, hydrogen propulsion is no longer just an idea - it is a reality.

Interested in deepening your knowledge of leak testing in hydrogen applications? Watch our free on-demand webinar on Leak Testing of Fuel Cells at your convenience to gain valuable insights from industry experts. Read also our article on practical solutions in real-world applications.

For deeper insights also see our Application Note about leak testing of hydrogen tanks.

Connect with Us at Global Automotive and e-Mobility Events!

We regularly attend major automotive and e-mobility exhibitions worldwide. Meet our experts, explore our latest innovations, and discuss your production challenges.