Monitoring H2 in Pipeline-Quality Natural Gas with Micro GC Fusion®

Pipeline-quality natural gas, or the gas that is used for consumption, has a percent of methane above 85%, with smaller concentrations of carbon dioxide, nitrogen, and C2–C6+ hydrocarbons. The analysis of natural gas is critical for a variety of users, including public utility companies, engine manufacturers, appliance manufacturers, and other industrial users.

Recent efforts to increase sustainability and reduce greenhouse gas (GHG) emissions have led to research into the injection of hydrogen into natural gas pipelines. Hydrogen, which emits no GHG emissions when burned, allows for a potential green source of energy and works toward a decarbonization solution. Hydrogen can only be added in amounts up to 30% in order to maintain use of current consumer appliances, such as gas stoves. Hydrogen in natural gas can be easily identified and quantified using gas chromatography.

Micro GC Fusion measures and reports gas component data in mole percentage, which is critical for understanding fuel composition and for calculating heating values and other gas properties. High-quality analytical data are beneficial for product development, performance, environmental compliance, and reporting. With its precision, small size, and speed of analysis, Micro GC Fusion is an ideal BTU analyzer capable of monitoring natural gas with added amounts of hydrogen.

Pipeline Natural Gas Analysis on Micro GC

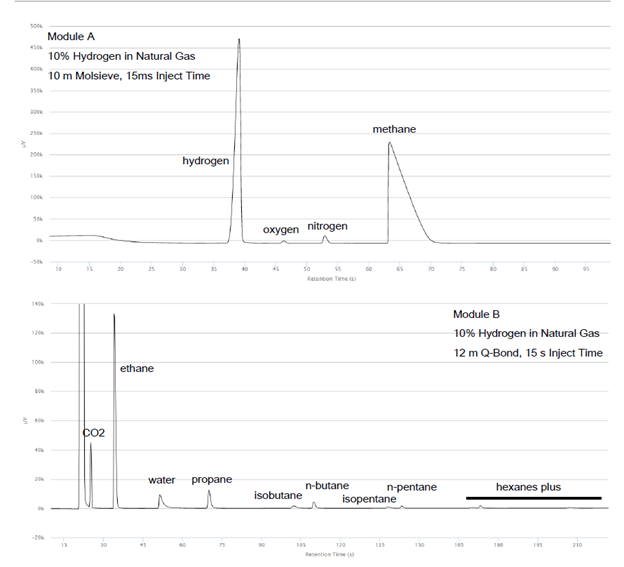

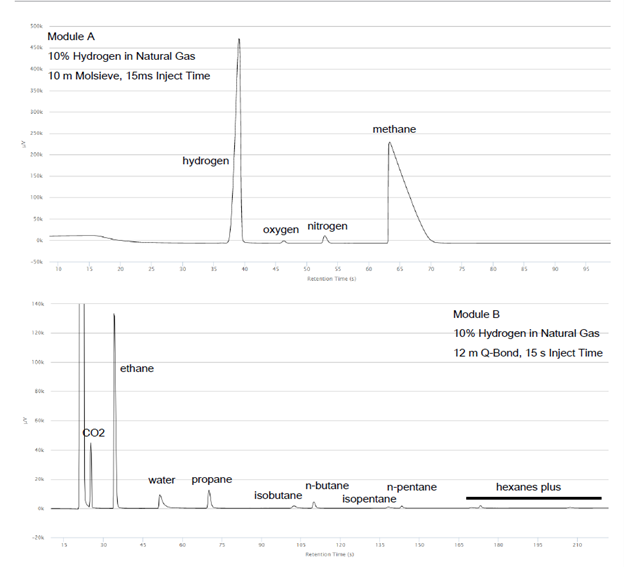

A two-module configuration was utilized for pipeline-quality natural gas analysis with hydrogen—a 10 m Molsieve module and a 12 m Q-Bond module. Each module was plumbed separately, allowing for maximum versatility.

A natural gas calibration standard was run on a two-module Micro GC Fusion to determine retention time, separation capability, the effects of carrier gas on the peaks, and repeatability. Hydrogen was added into this calibration standard from 1% up to 30% to investigate the behavior of the peaks in different carrier gases as well as the overall change in gross heating value.

Helium vs Argon for Hydrogen Detection

Helium provides excellent sensitivity for hydrocarbons and fixed gases—except for hydrogen. The thermal conductivity for hydrogen is very close to helium, resulting in reduced sensitivity. Furthermore, at higher concentrations of hydrogen, the peak begins to split and a peak inversion occurs, which makes integration difficult and inaccurate. The amount injected also plays a role in this phenomenon—the higher the injection time, the more the peak distorts.

The Q-Bond module shows excellent sensitivity and repeatability when using helium as a carrier gas, but it is only a viable option for the Molsieve column if the amount of hydrogen ranges from 1% to 10% and the injection time is less than 15 ms.

Argon carrier gas for hydrogen detection provides a stronger signal for hydrogen and is much more linear over a wide concentration range, but it results in reduced sensitivity for all other compounds. In addition, the Q-Bond module shows inversion of butanes, pentanes, and hexanes plus. With negative integration events, Micro GC Fusion can analyze these compounds, but with reduced sensitivity.

The ideal combination of carrier gases would be argon for the Molsieve module and helium for the Q-Bond module, as shown in the chromatograms. Micro GC Fusion can be configured for each module to run carrier gas independently, and this configuration results in the best sensitivity for hydrogen and the other natural gas components. In addition, there is no inversion of any peak.

Hydrogen Measurement in Natural Gas is Quick and Easy

The addition of hydrogen into a natural gas stream requires the use of a Molsieve module to analyze the concentration of hydrogen and its subsequent effects on the heating value of the gas. Using a two-module configuration with temperature programming, Micro GC Fusion can analyze hydrogen and a full range of natural gas components up to C6+ within minutes. Carrier gas choice is important; using only argon or only helium is viable in certain situations, but the most optimal configuration is both argon and helium for best sensitivity and repeatability. For higher amounts of butanes, pentanes, and hexanes plus, an additional Rxi-1ms module should be configured.

Let us know if you have any questions or would like to talk about your particular application, contact us today!