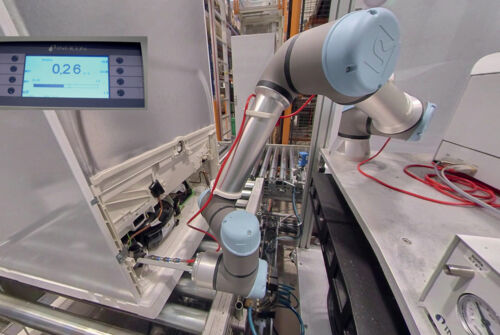

Revolutionizing Leak Detection with Robotics

The Future of Leak Detection in Refrigeration and Air Conditioning

In our continuous pursuit of innovation, we introduce new solutions in leak detection for Refrigeration and Air Conditioning (RAC) systems. Building on the foundation of our robotic technology, we present a comprehensive overview of the key features and advantages that our systems bring to the forefront.

Setting Up Initial Scans

For each refrigerator model type, an initial scan becomes the bedrock to establish the point of clouds. The visualization and segmentation of point clouds into smaller areas are crucial steps in our advanced leak detection process.

Defining Joints with I-GUIDE3D

Our technology focuses on the definition of joints and offers a comprehensive overview of these critical points.

The I-GUIDE3D package comprises 1 or 2 scanners, a controller (Beckhoff) with a software license, power supply, cables and all needed accessories for installation.

| Key features of the Scanner |

|---|

| The I-GUIDE3D is a customized software solution optimized for joint detection, robot path planning is seamlessly executed by the software, eliminating the need for intricate robot programming knowledge. Collision checks, singularity evaluations, and all major 6-axis robot brands can be seamlessly integrated. |

Robot and Vision System I-GUIDE3D: Robotic programming is required for specific parameters. To set up and install new models on the line, no robot programming skills are needed as the robot path planning is done by the software. The possibility to do a remote update or troubleshooting can be implemented to avoid downtimes.

Hidden Joints and Accuracy

Addressing the challenges of hidden joints, our I-GUIDE3D vision system will automatically check alternative movements or different ways of approaching the joint. Assigned numbers to each joint will provide precise feedback in case of a leak or missed joint. Tests over months showcase an accuracy rate exceeding 98-99%, and the system can be employed in applications beyond leak detection, such as induction brazing.

Free Whitepaper

Cycle Time Considerations

Differentiating between UR5 Cobot and industrial ABB IRB 1200 for various joint configurations, we highlight the cycle time for scanning and testing. Additional time considerations for moving in and out of the refrigerator and stabilizing the test object must be factored in.

Implementing a robotic sniffing system without changes in the manufacturing process may pose challenges when it comes to accessibility to the joints. However, our powerful I-TIP and I-GUIDE3D vision system is easy to implement and can eliminate these challenges. Our solution eliminates the need for intricate robot programming, making it an accessible and efficient choice. Note: While we deliver cutting-edge components for leak detection and localization, a system integrator is required for the seamless setup at customer sites.

Our comprehensive insights here provide a glimpse into our robotic leak detection solutions. For a deeper understanding, watch our On-Demand Webinar or explore our detailed Whitepaper.