Smart Sensors and Manufacturing Software for Semiconductor Process and Factory Optimization

Semiconductor manufacturers and their customers demand precision, efficiency, and control to maximize yield and throughput. As the industry faces new challenges, the need for autonomous semiconductor factories, aided by AI/ML, will be critical to its future success. INFICON Smart solutions are pivotal in shaping the future of the semiconductor industry. We provide a comprehensive suite of proven tools uniquely designed to optimize the entire semiconductor cycle, spanning from the front end to the back end of the semiconductor manufacturing ecosystem, and covering the subfab and facilities systems.

Smart Manufacturing Software Empowers Semi Manufacturing

Our Smart Manufacturing software suite offers the most widely deployed, comprehensive monitoring, control and factory optimization capabilities across semiconductor production lines. Our Digital Twin data warehouse combines factory data in real time into the critical reports and applications needed to make rapid decisions effectively. Tools like FabGuard® and SmartFDC® leverage advanced data analytics, machine learning, and predictive modeling algorithms to analyze vast amounts of real-time process data, identify potential deviations or anomalies, and proactively optimize process parameters to maximize yield and productivity, and predict the need for maintenance. Expanding into the subfab, INFICON’s Smart Manufacturing systems provide real-time monitoring and control to enhance excursion detection and drive factories toward greener operation by proactively controlling subfab and facilities systems to match consumable usage with production needs. FabControl provides integrated and comprehensive advanced process control solutions required for autonomous Smart Manufacturing. FabRecover provides dynamic, real-time preventive and corrective maintenance decision support and out-of-control action plans that support continuous improvement through data-driven analysis and review.

Our recent acquisition of FabTime, a specialist in cycle time management, highlights our commitment to providing a total solution for the next generation of chip fabrication.

By enabling predictive maintenance, fault detection, and process optimization, INFICON Smart Manufacturing software empowers semiconductor manufacturers to reduce downtime, improve product quality, and enhance operational efficiency, ultimately driving cost savings and realizing a competitive advantage.

Smart Sensors for Real-time Process Monitoring

At the heart of our solutions are INFICON Smart Sensors, instrumental in resolving or enabling next-generation semiconductor process challenges. Sensorization by INFICON accurately measures real-time process conditions including: trace gas concentrations, impurities, and process byproducts. INFICON empowers manufacturers to control processes with greater precision, leading to higher yield, better process control and reduced defects. Our process sensing technologies include:

Transpector® gas analysis systems have industry-leading data collection, speed and sensitivity. The advanced Transpector APX process monitor provides the longest lifetime on your ALD, CVD and Etch process for the best substrate protection and process optimization. Transpector MPH and XPR3+ are ideal for in situ air leak, gas purity, hydrocarbon and contamination monitoring. For real-time process monitoring in ALD, Etch, CVD and 300 mm Degas, explore Transpector CPM 3 with field-proven durability and reliability in these demanding applications.

For real-time leak detection, endpoint detection and process monitoring, rely on the INFICON Quantus® HP100 gas analyzer, based on Self-Plasma Optical Emission Spectroscopy (SPOES). The compact Quantus HP100 delivers excellent sensitivity, compact form factor and a wide operational pressure range without costly pumps, making it ideal for most semiconductor tools.

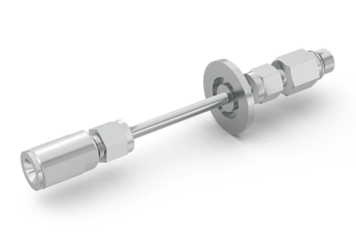

For precursor monitoring, SemiQCM can be installed in some of the harshest CVD or ALD chambers. Endpoint and fault elimination is realized by monitoring the amount of precursor in the foreline or chamber exhaust. The in situ SemiQCM provides affordable process monitoring and improved semiconductor process profitability.

As device architecture continues to grow vertically with increasing stacking layers in both memory and logic, accurate etch endpoint detection is becoming more challenging. INFICON’s suite of RF sensors provide real-time plasma monitoring for the most precise etch control, along with high-speed arc detection for additional wafer safety.

INFICON Smart Sensors help ensure optimal conditions for semiconductor deposition, etching and other critical processes. These Smart Sensors also play an important role in maintaining the sterile environment necessary for chip fabrication. These technologies detect even the smallest leaks in vacuum chambers, preventing contamination and ensuring the integrity of the final product. This focus on quality control helps semi manufacturers maintain high reliability and consistency in their chips.

INFICON understands the growing importance of sustainability in the semiconductor industry. Our Subfab and Facilities Control system assists manufacturers in optimizing energy consumption and consumable usage with a focus on reducing greenhouse gas emissions, thereby enhancing an environmentally friendly manufacturing process. Our Smart Tool-based Digital Twin enables engineers to collect data from a wide range of sensors, gauges, facilities and other devices to develop the most comprehensive view of process tools in the industry. Combining this robust collection of process information with subfab and facilities data provides a clear view of potential process impacts and better methods for control.

INFICON is a trusted partner to the world’s largest semiconductor manufacturers and an industry leader in instrumentation and software for process and factory optimization. Our diverse suite of solutions, from precise measurement tools to advanced software platforms, play a significant role in advancing semiconductor manufacturing. By focusing on accuracy, efficiency, quality, and sustainability, INFICON helps ensure the production of reliable and high-performance chips that power our increasingly interconnected world. With INFICON, you get worldwide expert support for your particular process needs.