SmartFDC® Machine Learning Fault Detection

A successful Fault Detection and Classification (FDC) system requires deep expertise in processes, equipment, and potential failure modes, as well as ongoing commitment to system setup and maintenance. However, even a fully configured FDC system is limited by the fault conditions anticipated during its design. While a well-engineered approach remains invaluable, machine learning algorithms—a powerful subset of Artificial Intelligence—offer significant advantages for both new and existing FDC programs.

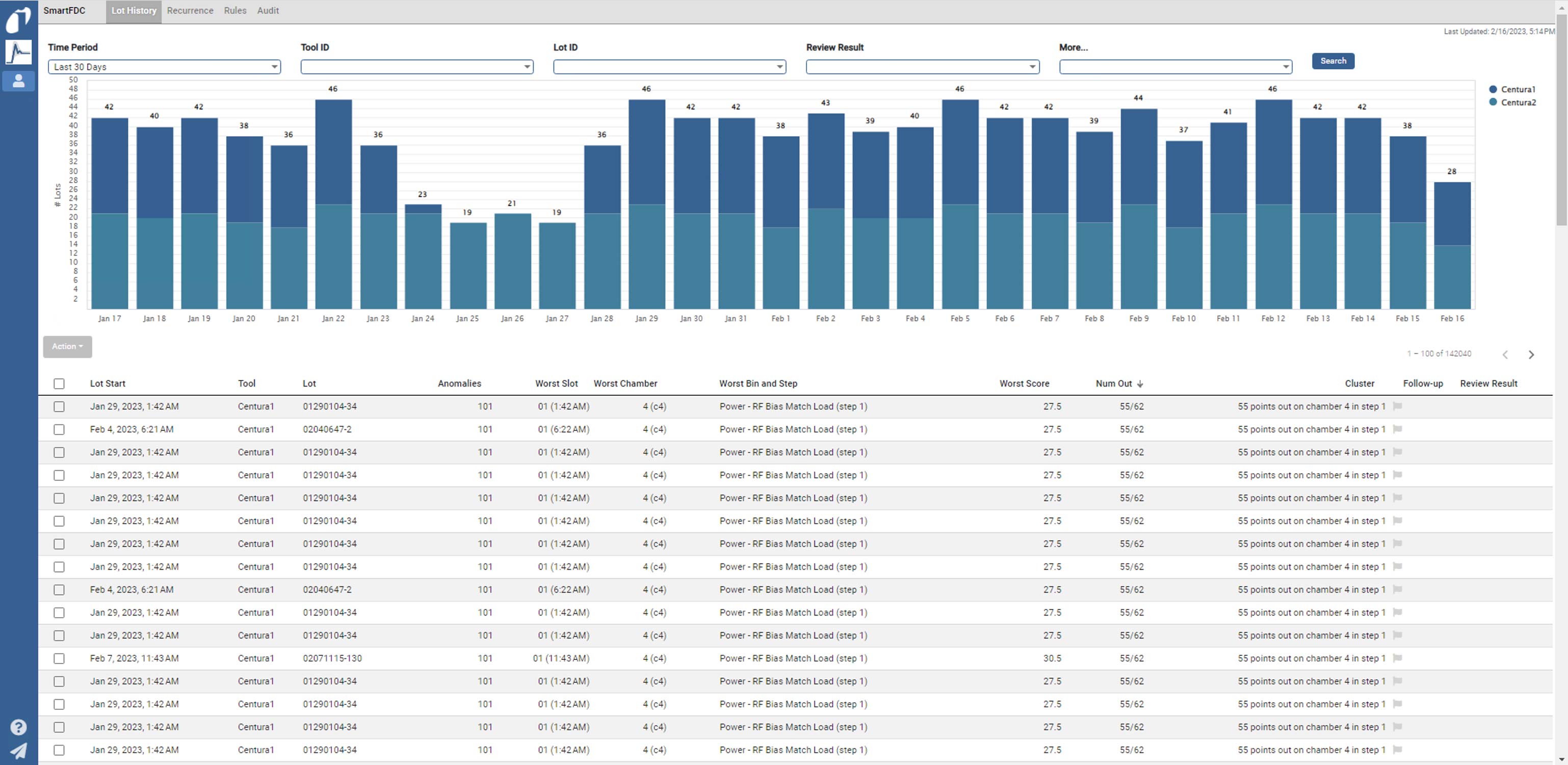

Harnessing the capabilities of these advanced algorithms, the Intelligent Manufacturing Systems group at INFICON has developed SmartFDC®. This innovative add-on automatically detects anomalies in time-series tool data, helping your FDC team quickly pinpoint issues that could lead to yield losses, ultimately enhancing efficiency and product quality.

Smart FDC Complements Standard FDC

With this system, data collected from each chamber uses Unsupervised Learning to automatically train the algorithm and report any detected anomalies.

Results of the analysis are displayed on an intuitive web-based user interface. From here you will be able to:

- View current and past anomalies including trend charts of process data

- Flag anomalies for follow-up

- Interact with the algorithm

- Filter down to results that are relevant to your job function

Easily Refine SmartFDC to Improve Accuracy

To enhance result accuracy, users can "teach" the algorithm through supervised learning, incorporating their engineering knowledge of the system. For instance, known trim violations, noise issues, or test wafer runs may trigger false anomalies. By training the system to recognize and ignore these false positives, users can refine the algorithm's future anomaly detection, ensuring more precise and reliable results over time.

Integrates with INFICON Software Products

The system also includes built-in integration capabilities with other INFICON products. For example, our Metrology Sampling Optimizer will allow you to configure a rule to automatically sample material at metrology if an anomaly is detected in SmartFDC.

Summary

With SmartFDC, you will be able to:

- Quickly establish baseline detection system for new tool installations or sensor hardware

- Reduce overall cost of ownership of FDC due to fewer resources required to maintain system

- Quickly adapt to process/technology changes without major effort to add/validate analyses

- Detect issues that may have not been conceived by an engineer

- Reduce product excursion risk by monitoring for the unexpected

SmartFDC is the next step in the evolution of our products enabling advanced capabilities in your factory.