Automated Leak Testing Secures Fuel Cell Quality for Heavy-Duty Trucks

Staufermatic Integrates INFICON Technology into Cellcentric’s Production Line

As fuel cell technology gains traction in the heavy-duty vehicle sector, manufacturers face increasing demands for efficiency, safety, and reliability. One critical challenge is ensuring that every fuel cell module is completely leak-tight before leaving the production line.

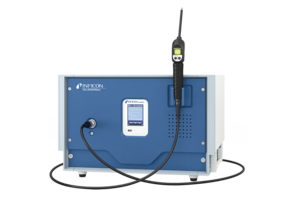

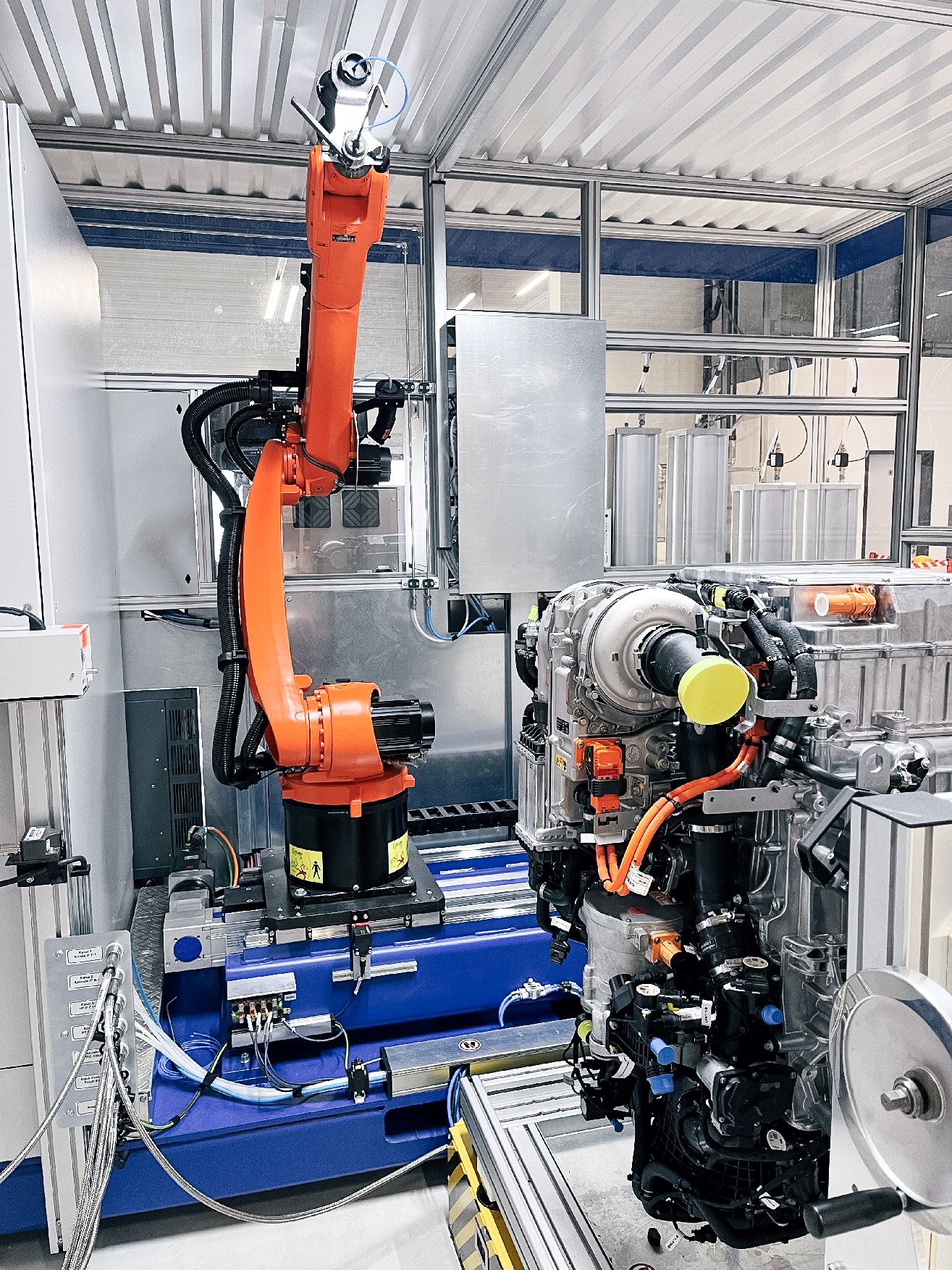

To meet this challenge, Staufermatic Maschinenbau has developed a fully automated robotic leak testing system for Cellcentric, the fuel cell joint venture of Daimler Truck and Volvo Group. The system relies on INFICON’s XL3000flex sniffer leak detector, a high-performance solution designed for precise and efficient helium-based leak detection.

Robotic Precision for High-Volume Production

Fuel cell production at Cellcentric includes 100 kW and 150 kW modules, with future variants in development. Staufermatic’s automated system is designed for maximum flexibility, allowing multiple generations of fuel cells to be tested without major modifications.

The robotic leak detection system checks up to 25 critical points on each module, using helium as a tracer gas. Hydrogen itself is not suitable, as it would interfere with the fuel cell’s electrical components.

"The high gas flow rate of the XL3000flex - 3,000 sccm compared to the usual 60 sccm - was a game-changer for us," Raab explains. "It enables fast and highly sensitive leak detection, even in deep or hard-to-reach areas."

The system operates at different test pressures, depending on the component:

- 2 bar for the full module

- 19 bar for high-pressure hydrogen lines

"Testing at higher pressures accelerates the process and enhances sensitivity, ensuring even the smallest leaks are detected," says Raab.

A Leap Forward in Leak Detection Efficiency

Compared to manual sniffer leak testing, the robotic system offers key advantages:

- Higher repeatability – Eliminates operator errors

- Faster cycle times – Reduces production delays

- Improved access – Reaches deep and complex areas

- Scalability – Easily adapts to future cell designs

"With automation, we eliminate human error and ensure every fuel cell module meets the highest quality standards," Raab emphasizes.

Potential for Expansion into Battery Testing

While the system is currently focused on fuel cells, Staufermatic sees potential for future EV battery leak testing.

"End-of-line leak testing is just as critical for batteries as it is for fuel cells," Raab notes. "INFICON’s high-flow helium detection technology could play a key role in ensuring battery enclosures and cooling systems are completely sealed."

With INFICON’s advanced leak detection technology and Staufermatic’s automation expertise, Cellcentric is setting new standards in fuel cell production - helping to accelerate the transition to zero-emission heavy-duty transportation.

Download Free Whitepaper

Connect with Us at Global Mobility and Automotive Events!

We regularly attend major semiconductor exhibitions worldwide. Meet our experts, explore our latest innovations, and discuss your production challenges.

Learn more about an evolving market and leak testing standards