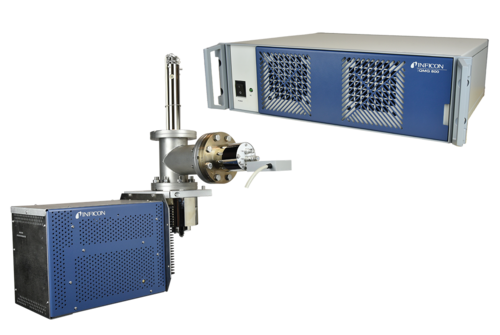

QMG 800

Pushing Boundaries with Unmatched Sensitivity, Precision, and Superior Analytical Capabilities

The INFICON QMG 800 is the next-generation analytical mass spectrometer, succeeding QMG 700. QMG 800 remains the market-leading Residual Gas Analyzer (RGA) for analytical process monitoring.

Recognizing customers’ unique needs, INFICON built the QMG 800 to allow for more flexibility to meet specific application requirements while maintaining industry-leading measurement speed and sensitivity. QMG 800 is designed to offer enhanced performance and reliability for a wide range of analytical mass spectrometry applications. It is the ideal choice for precise and accurate analysis in contamination monitoring processes, ensuring the highest levels of purity and quality control in various industries. Users will appreciate the digital advances of QMG 800, which incorporates cutting-edge technologies to enhance performance and experience.

With more than 50 years of pioneering excellence in analytical mass spectrometry, the INFICON QMG 800 sets a new standard for your gas analysis investments. Experience unparalleled accuracy and precision, backed by our global expertise and commitment to innovation.

Choose the QMG 800 for results you can trust every time.

Features

- Advanced digital platform allows communication over OPC UA

- Seamless OEM integration

- Ion source options for diverse applications

- Fully compatible with the complete FabGuard® software suite for unparalleled diagnostics

- 90° off-axis SEM to minimize noise from radicals and non-ionized particles

- Unparalleled precision and sensitivity with single ion detection capabilities

- Industry-leading measurement speeds at 125 microseconds per AMU

Typical Applications

- Contamination detection

- Gas purity monitoring

- End point detection

- Molecular beam epitaxy monitoring

Specifications

| Mass Range | 1-512 amu |

| Rod Material | Molybdenum |

| Max. Operating Pressure (EM) | 1 E-5 mbar |

| Faraday Sensitivity | |

| Axial Ion Source | 3E-4 A/mbar |

| Cross Beam Ion Source | 7E-5 A/mbar |

| Cross Beam Gas Tight Ion Source | 7E-5 A/mbar |

| Cross Beam Ion Source with Magnets | 7E-4 A/mbar |

| Cross Beam Gas Tight Ion Source with Magnets | 7E-4 A/mbar |

| Grid Ion Source | 2E-4 A/mbar |

| Resolution (adjustable) | 0.3 - 7 amu |

| Minimum Detectable Partial Pressure | 1 E-15 mbar |

| Partial Pressure Ratio with Electron Multiplier | < 0.5 ppb |

| Max. Operating Temp. (Sensor & Electronics) | 150 °C |

| Measurement Speed | 0.125 ms - 60 s/amu |

| Mass Range | 1-300 amu |

| Rod Material | Stainless Steel |

| Max. Operating Pressure (EM) | 1 E-5 mbar |

| Faraday Sensitivity | |

| Axial Ion Source | 2E-4 A/mbar |

| Cross Beam Ion Source | 8E-5 A/mbar |

| Cross Beam Gas Tight Ion Source | 8E-5 A/mbar |

| Cross Beam Ion Source with Magnets | 7E-4 A/mbar |

| Cross Beam Gas Tight Ion Source with Magnets | 7E-4 A/mbar |

| Grid Ion Source | 2E-4 A/mbar |

| Resolution (adjustable) | 0.3 - 7 amu |

| Minimum Detectable Partial Pressure | 2E-15 mbar |

| Partial Pressure Ratio with Electron Multiplier | < 1 ppb |

| Max. Operating Temp. (Sensor & Electronics) | 150 °C |

| Measurement Speed | 0.125 ms - 60 s/amu |