FabGuard® FDC

Smart Monitoring for Smarter Manufacturing

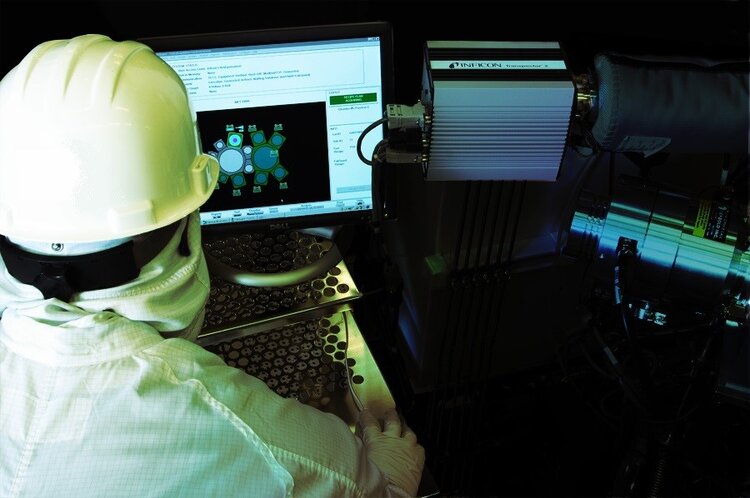

INFICON FabGuard is the industry-leading process monitoring and fault detection system designed for semiconductor and high-tech manufacturing. By leveraging real-time data analytics and AI-driven insights, FabGuard helps you detect issues before they impact production, reduce downtime, and enhance yield efficiency.

With seamless integration across fab equipment, FabGuard ensures higher throughput, lower defect rates, and increased operational confidence—giving you the competitive edge in precision manufacturing.

Real-Time Process Monitoring for Smarter Manufacturing

INFICON’s FabGuard FDC System delivers unmatched connectivity, data collection, and actionable insights to optimize semiconductor manufacturing. Engineers gain deep visibility into tool performance and process efficiency, enabling smarter decision-making and continuous improvement. Beyond traditional Fault Detection and Classification (FDC) methods, FabGuard leverages SmartFDC® with advanced unsupervised Machine Learning to automatically detect process shifts—ensuring faster response times, improved yield, and maximized production efficiency.

Advantages

- Seamless integration of process equipment and sensor data

- Edge computing

- On premises or cloud-based

- Real-Time and Run-by-Run analysis

- World-class connectivity to sensors, gauges, IoT/ IIoT, process tools

- Automatic Machine Learning

Intelligent Process Monitoring and Control

FabGuard is an advanced process monitoring system that empowers engineers with comprehensive, real-time insights across a wide range of sensors, gauges, facilities, and devices. By seamlessly integrating data from multiple sources, FabGuard provides unparalleled visibility into process tools, enabling smarter decision-making, improved process control, and enhanced manufacturing efficiency.

- Sensors: RGA, OES, RF/DC, Quartz Crystal Microbalance

- Gauges: Wide Range Vacuum, High Precision Vacuum, Mass Flow, Liquid Flow

- Facilities: Pumps, Abatement, Heaters, Chillers, Chemical Delivery

- High Speed: Accelerometer, Arc Detection, High Speed Analog

With adaptive, real-time data collection, FabGuard ensures the right data is captured at the right time—critical for accurate fault detection and process characterization. Its dynamic data collection capabilities optimize tool bandwidth, maximizing the depth and breadth of data without compromising performance. By adjusting in real time to process conditions, sensors, and tool components, FabGuard delivers smarter insights, faster responses, and superior process optimization.

Expertise that Transforms Your Factory

INFICON brings deep process and equipment expertise to every factory, helping engineers solve real-world manufacturing challenges with precision and efficiency. Our field service and software development teams are industry veterans, ensuring that FabGuard is tailored to meet the unique demands of your production environment.

With experience across all wafer diameters, flat panel sizes, device geometries, and substrate types, INFICON supports fabs at every level—whether operating with minimal automation or fully automated smart manufacturing systems. By combining advanced technology with hands-on industry knowledge, we help you optimize processes, enhance tool performance, and drive higher yields.

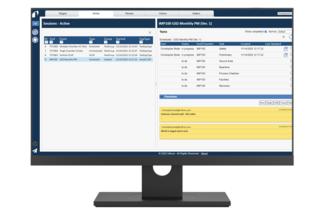

Ask INFICON Our AI-Powered Expert

Built on advanced large language model (LLM) technology, Ask INFICON delivers real-time support, helping semiconductor manufacturers quickly access essential product knowledge. Integrated with the FabGuard Web application, the knowledge assistant incorporates FabGuard Help, training materials, sensor documentation, and other end-user resources, allowing engineers and operators to troubleshoot issues, understand fault detection and sensorization concepts, and enhance their understanding of FabGuard capabilities—all within a seamless AI-driven interface.