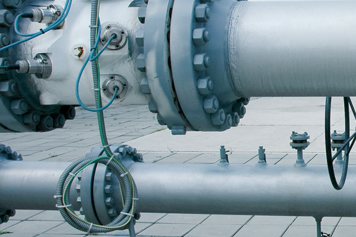

Subfab and Facilities

Smart Subfab Control for Greener Factories

Fault Detection and Control for the Subfab and Facilities

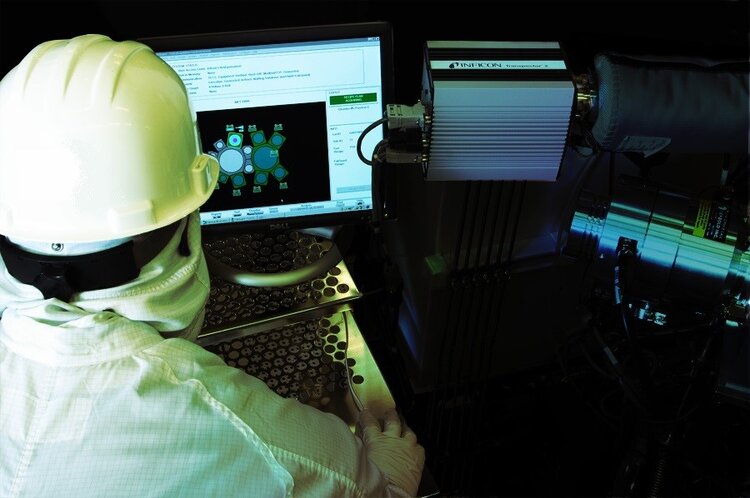

Our Edge-Based Computing FabGuard Facilities Monitoring System and HMI provides integration of facilities and subfab components with process information. Working alongside with data collected from the process equipment, INFICON makes it possible to manage and control multiple subfab/facilities components.

Advantages

- Smart control/Energy savings

- Migrate to condition-based consumption

- Regulatory compliance and reporting

- Increase FDC tool and process fidelity

- Smart and Predictive maintenance scheduling

Connect the Process with the Subfab/Facilities

FabGuard enables engineers to collect data from a wide range of sensors, gauges, facilities, and other devices to develop the most comprehensive view of process tools in the industry.

- Pumps: Drive Current, Temperatures, Pressures, Purge Flows, Vibrational, Alarms

- Abatement: Gas Consumption, Operational Values, Alarms

- Exhaust: Differential Pressure, Temperature, Byproduct Deposition

- Heaters: Heater Current/Voltage, Temperature

- Chillers: Flow Rates, Temperature

Combine process information with the subfab and facilities data to obtain a clear view of potential process impacts and provide better methods for control. INFICON uses FabGuard to predict excursions, manage maintenance activities, and identify opportunities for cost savings.

Lower Costs and Be Green

While manufacturers strive to minimize idle time, equipment idle periods provide an opportunity to minimize waste resulting in lower costs and a more green operation.

By utilizing real-time Factory Scheduling and equipment state information, FabGuard controls subfab and facilities components to minimize usage of power and consumables. This includes making use of Green operation and Idle modes.