UL1000 / UL1000 Fab

Mobile Helium Leak Detectors with ULTRATEST™ sensor technology.

The Standard for Vacuum Leak Testing in Industrial Vacuum and Semiconductor Manufacturing

The INFICON UL1000 Helium Leak Detector Series is the renowned standard when it comes to economic helium vacuum leak testing in industrial (UL1000 with oil-sealed fore vacuum pumps) or semiconductor environments (UL1000 Fab with dry compressing fore vacuum pumps).

The UL1000 Series provides the best compromise between high performance, unparalleled robustness, and affordability. It delivers state-of-the art detection limits of 10-12 mbar*l/s combined with reasonable short pump down and response time. The compact design ensures high maneuverability facilitating easy access to maintenance areas with restricted space. The selectable background suppression (iZERO) allows for continuous leak testing within at least two decades lower than existing background levels.

These features collectively reduce the duration of your leak testing process while ensuring all leaks are detected efficiently and economically.

With the addition of the TC1000 Test Chamber accessory, the UL1000 Helium Leak Detector Series provides easy, fast and accurate testing of hermetically sealed parts like IC packages, quartz crystals and laser diodes (according to MIL-STD 883, Method 1014).

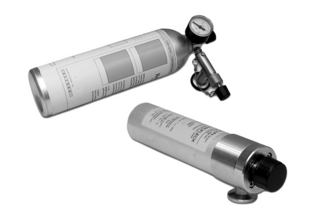

Essential Accessories: SMART-Spray, SPRAY-Check

The SMART-Spray helium spray gun enhances leak checking by eliminating the need for large helium cylinders and cumbersome hoses. It streamlines the process, reducing manual helium flow adjustments and minimizing errors. This tool makes leak detection faster, easier, and more reliable while maintaining low helium consumption and background levels. Ideal for efficient and precise leak testing.

SPRAY-Check, a spray on test leak, ensures the functionality and readiness of your leak detector. Ideal for the 10⁻⁹ to 10⁻⁸ mbar∙l/s range, it provides reliable checks during testing processes.

Advantages

- minimize leak testing efforts through quick pump down and response time

- avoid need for multiple leak tests by using selectable background suppression (I·ZERO)

- I·CAL (Intelligent Calculation Algorithm for Leak rates)to ensure fastest response time to leaks in all measurement ranges

- enable easy access to maintenance areas with restricted space through maneuverable design

- low total cost of ownership (TCO) enabled by robust two hot filament ion source (3 years warranty) and counterflow vacuum system

- easy to use with rotatable display, optical and audible leak indication, and optional remote control

- low maintenance via a built-in test leak with auto calibration procedure

- Software updates via email easily possible

- Built-in software menu "Auto Leak Test" function to perform automatic testing of hermetically sealed components (optional TC1000 Test Chamber)

Typical Applications

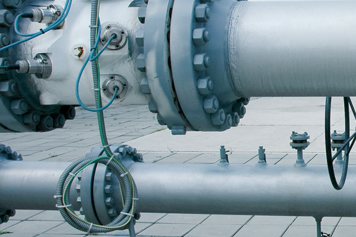

- industrial vacuum equipment manufacturing with high demand for cleanliness

- vacuum components or sub-assemblies before they are installed in existing tools

- maintenance work on vacuum tools, with or without support from their own pump

- inspections and installations of process gas systems

- semiconductor, flat panel display or solar cell manufacturing

- automotive components

- refrigeration and air conditioning components and sub-assemblies hermetically sealed electronic devices

- heat exchangers

Specifications

| Min. detectable leak rate for helium (vacuum method) | mbar•L/s | < 5·10-12 |

| Min. detectable leak rate for helium (sniffer mode) | mbar•L/s | < 5·10-8 |

| Max. Inlet pressure GROSS mode | mbar | 15 |

| Max. Inlet pressure FINE mode | mbar | 2 |

| Max. Inlet pressure ULTRA mode | mbar | 0.4 |

| Fore vacuum pump type | Oil-sealed | |

| Pumping speed during evacuation | m³/h | 16 at 50 Hz |

| Helium pumping speed ULTRA mode | L/s | 2.5 |

| Detectable masses | 2,3,4 amu | |

| Mass spectrometer Sector field | 180° | |

| Filaments ion soure Iridium/Yttria coated | 2 | |

| Calibrated built in test leak | mbar•L/s | E-7 |

| Test port | DN 25 KF | |

| Adjustable triggers | 2 | |

| Interface | RS232 | |

| Chart recorder output | V | 2x10 |

| In/Outputs | PLC compatible | |

| Permissible ambient temperature (during operation ) | °C | +10.....+40 |

| Weight | kg lb | 110 242 |

| Dimensions ( L x W xH ) | mm in | 1068 x 525 x 850 42 x 21 x 33 |

| Supply voltages | V (AC) V (AC) V (AC) | 230 (±10%) 50Hz 115 (±10%) 60Hz 100 (±10%) 50/60Hz |

| Power consumption | VA | 1100 |

| Min. detectable leak rate for helium (vacuum mode) | mbar•L/s | < 5·10-12 |

| Min. detectable leak rate for helium (sniffer mode) | mbar•L/s | < 5·10-8 |

| Max. Inlet pressure GROSS mode | mbar | 15 |

| Max. Inlet pressure FINE mode | mbar | 2 |

| Max. Inlet pressure ULTRA mode | mbar | 0.4 |

| Fore vacuum pump type | Dry compressing | |

| Pumping speed during evacuation | m³/h | 25 at 50 Hz |

| Helium pumping speed ULTRA mode | L/s | 2.5 |

| Detectable masses | 2,3,4 amu | |

| Mass spectrometer Sector field | 180° | |

| Filaments ion source Iridium/Yttria coated | 2 | |

| Calibrated built-in leak | mbar•L/s | ∼ 10-7 |

| Test port | DN 25 KF/(DN 40 KF) | |

| Adjustable triggers | 2 | |

| Interface | RS 232 | |

| Chart recorder output | V | 2 x10 |

| In/Outputs | PLC compatible | |

| Permissible ambient temperature (during operation) | °C | +10 to +40 |

| Weight | kg lb | 110 242 |

| Dimensions (l x w x h) | mm in. | 1050 x 472 x 987 41 x 19 x 39 |

| Supply voltage (EU) | V (AC) | 230 (± 10 %) 50 Hz |

| Supply voltage (US) | V (AC) | 100/115 V (± 10 %) 50/60 Hz |

| Power consumption (typ.) | VA | 1100 |

| Power consumption (max.) | VA | 1100 |

Ordering Information

| 550-000A | UL1000, 230 V AC, DN 25 KF |

| 550-001A | UL1000, 115 V AC, DN 25 KF |

| 550-002A | UL1000, 100 V AC, DN 25 KF |

| 550-100A | UL1000 Fab, 230 V AC, DN 25 KF |

| 550-101A | UL1000 Fab, 100/115 V AC, DN 25 KF |

| 550-102 | UL1000 Fab, 230 V AC, DN 40 KF |

| 551-050 | SMART-Spray helium spray gun set |

| 551-031 | SPRAY-Check TL8 (not calibrated) |

| 14005 | SL200 - 4 m, Sniffer Probe for UL product family |

| 14006 | SL200 - 14 m, Sniffer Probe for UL product family |

| 14022 | Extension cable for remote control RC1000, 8 m length |

| 551-000 | Toolbox, detachable for UL1000 |

| 551-001 | Helium Bottle Holder for UL1000/5000 |

| 551-002 | ESD Mat for UL1000/5000 |

| 551-005 | TC1000 Test Chamber, DN 25 KF, ESD wrist band |

| 551-010 | Remote Control RC1000C, wired, with 4 m coiled cable |

| 551-015 | Remote Control RC1000WL, wireless, incl. wireless transmitter |

| 551-020 | Wireless transmitter for RC1000WL |

Downloads