UL3000 Fab Series

UL3000 Fab /UL3000 Fab ULTRA

Mobile Helium Leak Detectors with ULTRATEST™ sensor technology

Mobile Helium Leak Detectors: Specifically designed for the needs of leak checking in semiconductor applications.

They feature flexibility, mobility, fast start up, high sensitivity, fast and precise test results, and reliability.

- Faster pump down (evacuation) times due to higher air pumping speed.

- Lower total cost of ownership (TCO) due to low maintenance roots roughing pump.

- Start leak checking earlier as HYDRO·S software eliminates the water vapor background, making it possible to quickly reach sensitive measurement ranges

- The UL3000 Fab ULTRA leak detector offers also an improved sniffer capability by using the well proven sniffer line SL3000 which has up to 10 m length. The SL3000 has a separate connection port, thus no connection to the vacuum inlet is required.

Fast Results

The improved vacuum system with low maintenance vacuum pumps allows the detection of leaks starting from atmospheric pressure. The rugged mass spectrometer system ensures long running time and low maintenance costs.

Rotatable Display and Remote Controllable User Interface

The innovative touch screen display shows test results and status information even from a long distance. Easy operation via user guided menu structure, even for inexperienced operators. A wireless control of the UL3000 Fab (ULTRA) helium leak detector is possible via smartphone or tablet - without special software or Apps. Recording and storage of test results via push button can be transferred to other storage media for further analysis.

Slim Design for Advanced Maneuverability

A low center of gravity, big wheels, ergonomically designed handle and the slim housing enable good mobility of the UL3000 Fab (ULTRA) even in tight spaces.

Optimized Leak Testing with SMART-Spray, I·BOOST and SPRAY-Check

SMART-Spray helium spray gun enhances leak checking by eliminating the need for large helium cylinders and cumbersome hoses. It streamlines the process, reducing manual helium flow adjustments and minimizing errors. This tool makes leak detection faster, easier, and more reliable while maintaining low helium consumption and background levels. Ideal for efficient and precise leak testing.

I·BOOST offers up to 50% time savings in leak detection. With shorter response times, it delivers fast and precise measurements across various chamber volumes, enhancing efficiency and accuracy. Additionally , SPRAY-Check, a spray on test leak, ensures the functionality and readiness of your leak detector. Ideal for the 10⁻⁹ to 10⁻⁸ mbar∙l/s range, it provides reliable checks during testing processes.

Advantages

- Save Time with I·CAL software algorithm for fast measurements in the range of 10-9 to 10-12 mbar·l/s

- Most efficient leak checking using I·ZERO 2.0 with improved intelligent function for fast background suppression while maintaining high measurement sensitivity

- Applicable for vacuum and sniffer leak search

- Minimize leak checking efforts through quick evacuation and response time

- Time saved by easy maneuverability through slim design

- Low total cost of ownership (TCO) enabled by robust ion source (3 year warranty) and counterflow vacuum system

- Easy to use, operator-guided HMI with full color high resolution rotatable display

- UL3000 Fab ULTRA: Start leak checking earlier as HYDRO·S software eliminates the water vapor background, making it possible to quickly reach sensitive measurement ranges

- UL3000 Fab ULTRA: Faster pump down (evacuation) times due to higher air pumping speed of roots pump

- UL3000 Fab ULTRA: Lower total cost of ownership (TCO) due to low maintenance roots roughing pump.

- UL3000 Fab ULTRA: The leak detector offers also an improved sniffer capability by using the well proven sniffer line SL3000 which has up to 10 m length. The SL3000 has a separate connection port, thus no connection to the vacuum inlet is required.

Typical Applications

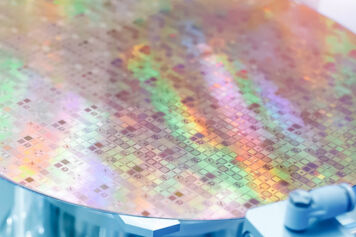

- Semiconductor Fabs

- Flat Panel Display manufacturing

- Solar Cell fabrication

- Glass and Web (roll to roll) coating

- General vacuum coating & applications

Specifications

| Max. pumping speed of roughing pump | m³/h | >30 |

| Helium pumping speed (high sensitive mode ULTRA) | L/s | 4 |

| Dimensions (LxWxH) | mm in. | 1050x472x987 42x21x34 |

| Additional Features | Roots dry pump with highest air pumping speed, HYDRO·S, separate sniffer line port for SL3000, vacuum hose holder | |

| Max. pumping speed of roughing pump | m³/h | >36 |

| Helium pumping speed (high sensitive mode ULTRA) | L/s | 4 |

| Dimensions (LxWxH) | mm in. | 1050x472x987 42x21x34 |

| Additional Features | Roots dry pump with highest air pumping speed, HYDRO·S, separate sniffer line port for SL3000, vacuum hose holder | |

Ordering Information

| 550-260 | UL3000 Fab ULTRA |

| 550-200 | UL3000 Fab |

| 551-050 | SMART-Spray Helium Spray Gun***NEW |

| 551-600 | I·BOOST software license***NEW |

| 551-031 | SPRAY-Check Test Leak TL8***NEW |

| 551-010 | Remote Control RC1000C, wired, with 4m coiled cable |

| 551-202 | Vacuum Hose Holder for UL3000 Fab (incl. for ULTRA version) |

| 14005 | SL200 - 4 m, Sniffer Probe for UL product family |

| 14006 | SL200 - 14 m, Sniffer Probe for UL product family |

| 525-003 | SL3000-10, sniffer line 10 m length |

| 525-001 | SL3000-3, sniffer line 3 m length |

| 525-002 | SL3000-5, sniffer line 5 m length |

| 551-203 | Bracket for SL3000 |

| 551-210 | SL200, Sniffer line + el. extension for UL3000 |

| 551-201 | Helium Bottle Holder |

| 560-310 | I/O 1000 module |

| 560-315 | BM1000 PROFIBUS module |

| 560-316 | BM1000 PROFINET IO module |

| 560-317 | BM1000 DeviceNet module |

| 560-318 | BM1000 Ethernet/IP module |

| 560-334 | Data Cable for IO1000, BM1000, 0.5m |

| 560-332 | Data Cable 2 m |

| 560-335 | Data Cable 5 m |

| 560-340 | Data Cable 10 m |

| 551-005 | TC1000Test Chamber, DN25KF, ESD wrist band |

| 551-205 | Extension cable for TC1000/SL200, UL3000 |

| 200007656 | Airfilter Kit UL3 Housing Ventilation |