RF Sensing Technology

Our cutting-edge RF sensing technology provides non-invasive solutions for real-time plasma monitoring, wafer etching, and process control in industrial environments. With precise arc detection and endpoint control, our sensors enhance efficiency, protect against arc events, and lower operational costs. Designed for high-speed data collection, they ensure optimized performance in semiconductor manufacturing processes.

Reset the filters to get results.

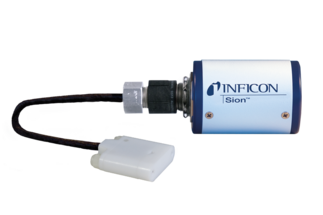

Non-Invasive, Clamp-On RF Detector Delivers High-Speed Arc Detection and Clean End Point Control for higher yields and reduced Cost of Ownership

- Easy retrofit to existing tool set and drop-in replacement for OES-based instrument for endpoint control

- Non-invasive sensor installation

- High-speed data collection (250 kHz) for arc detection

- Eliminates chamber clean under- and over-etching, increasing uptime and reducing cost of gas usage and materials

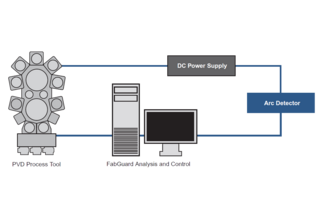

- Integrated data management with FabGuard

Non- Invasive, high speed, DC arc dection for real-time process control

- Software integration to the tool through FabGuard Sensor Integration and Analysis System

- Data collection at 250 kHz per channel

- Custom cables connect to most DC generators

- Detects arcs quickly with pre-defined analysis tools

Plasma Monitoring Accuracy with INFICON's RF Technology

Achieving precise process control in semiconductor manufacturing requires the right tools. INFICON's RF sensing technology, including the Sion™ and ADC100, offers powerful solutions for real-time plasma monitoring and wafer etching. The Sion™ provides continuous feedback, ensuring accurate endpoint detection to avoid over-etching and material waste. Similarly, the ADC100 delivers superior arc detection and protection, safeguarding your equipment while maintaining production efficiency.

Whether managing delicate plasma conditions or ensuring consistent etch quality, INFICON's RF sensor technology minimizes downtime and maximizes efficiency. With their robust design, both the Sion™ and ADC100 withstand harsh environments while delivering peak performance, making them essential tools for high-stakes production.

Integrating INFICON's RF sensing solutions into your process improves workflow reliability, streamlines operations, and minimizes downtime. With these advanced tools, you can achieve faster, more accurate manufacturing results, enhancing your competitive edge.