Products

We offer a diverse product portfolio, including solutions for leak detection, gas analysis, and vacuum technology

Reset the filters to get results.

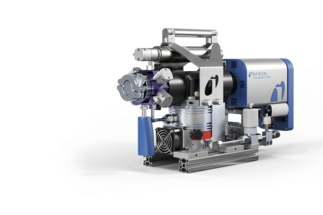

Advanced process expert for Multi-Pressure ALD/CVD and Etch.

- xParts coated for extended lifetime in harsh chemistry

- Multi pressure sampling inlet

- Detection limit below 10 ppb

- Industry leading pumping speed

Advanced process expert for Single Pressure ALD/CVD and Etch.

- xParts coated for extended lifetime in harsh chemistry

- High temperature single pressure inlet

- Detection limit below 10 ppb

- Industry leading pumping speed

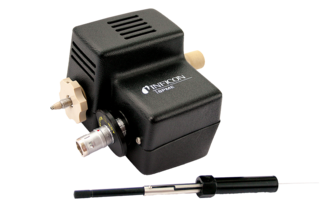

Modular leak detector, compact Performance at the Highest Level

- More Compact And Easier To Integrate

- Communicative Diversity

- High Reliability

The Factory Digital Twin is the most critical building block for developing a Smart factory. It collects all the real-time operations events to compute cycle time and throughput data to drive powerful applications.

- Provides a universal platform to which production data can be loaded from multiple resources.

- Facilitates translation of data into information, thereby driving the function of all connected solutions.

- Central and foundational core of Smart Manufacturing

For all jobs, big or small

- 275 lb. (125 kg) capacity platform designed to fit all tank sizes

- Wired handpiece with bright, backlit LCD display

- Bluetooth connectivity with free mobile app

- 0.1 oz (3 g) resolution for critical charging of all refrigerants including A3 flammables

- Compatible with small charge adapter kit (PN 501-601-G1) for mounting A3 refrigerant bottles

- Over the air (OTA) remote upgradeable

Medium to Ultra High Vacuum SingleGauge

- Pure Bayard-Alpert measuring system for a wide UHV & HV measurement range

- 2 filaments for Bayard-Alpert system

- Galvanic isolated electronics to avoid electric stray current

- Sliding emission mode to avoid pressure jumps

ATM to Ultra High Vacuum TripleGauge®

- 3 + 1 sensing elements for extremely wide measurement range, cost reduction & space savingness

- 2 filaments for Bayard-Alpert system

- Gas type independent pressure measurement above 10 Torr for reliable load lock control.

- Differential pressure measurement eliminates uncertainty related to atmospheric pressure changes

ATM to Ultra High Vacuum DualGauge

- DualGauge (2 sensing elements) for a wide measurement range, cost reduction & space savingness

- 2 filaments for Bayard-Alpert system

- Pirani interlock protection to avoid premature filament burnout

- Sliding emission mode to avoid pressure jumps

- DN10-DN50

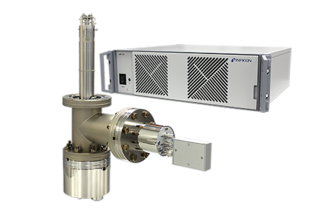

Extreme PVD Process Monitoring Quadrupole Mass Spectrometer

- Industry leading maximum operating pressure

- Optional overpressure isolation valve interlock

- Scans up to 100 amu

HIGH FLOW technology for highest measurement certainty and fastest throughput.

- INFICON High Flow Technology

- Enables unmatched measurement certainty - stop missing leaks!

- Finds leaks even in hard to access areas

- Helps unexperienced operators to reliably locate leaks

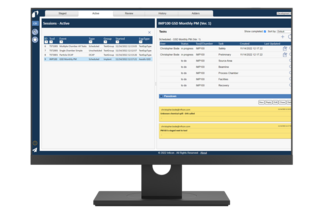

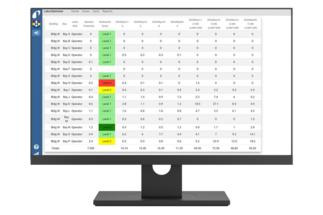

The Factory Dashboard is the principal operations reporting tool used by industry-leading fabs around the world.

- Enables quick response to machine and WIP issues

- Increases all factory personnel awareness

- Improves reaction time of personnel

- Improves alignment of operations with planning

ATM To Medium Vacuum Gauge - High volume standard applications

- Easy push button ATM and HV adjustment

- Space saving rugged design

- Stainless steel measuring cell with metal-sealed feedthrough

- Mounts in any orientation

A knowledge-based, decision support software platform specifically designed to help factories return tools to production quickly and correctly.

- Step-by-step, dynamic guidance and needed support for BKM work

- Root cause analysis and identification based on historical and heuristic data trends

- Modeled linkage between control system events, troubleshooting, and remediation

Provides integration of facilities and subfab components with process information.

- Smart control/ Energy savings: Reduced energy usage by linking tool states to facilities

- Migrate to condition-based consumption: Reduced use of consumables/chemicals/gases (reduction of 15-50% typical)

- Smart and Predictive maintenance scheduling: Use data to create predictive maintenance routines

Provides unparalleled capability to automatically translate collected data into meaningful information.

- Automatic Machine Learning of factory processes

- Comprehensive visualization and analysis tools

- Provide augmentation for existing 3rd party FDC

Smart Fault Detection and Classification provides real time data integration and analysis to predict excursions before they happen.

- Seamless integration of process equipment and sensor data allows data from multiple sources to be available for analysis

- Edge computing enables data collection and analysis to happen at the source for faster response and enhanced detection

- On Premises or Cloud-based installation offered to allow maximum flexibility of performance and cost

- Real Time and Run-by-Run analysis reduces scrap and improves process control

Simple operation, outstanding durability and great accuracy.

- Durable weighing platform

- Measures in lb., lb./oz., or kg

- Simple controls

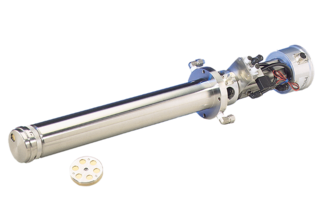

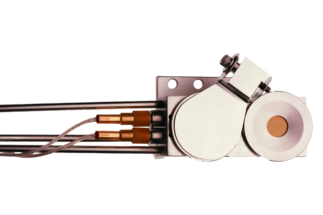

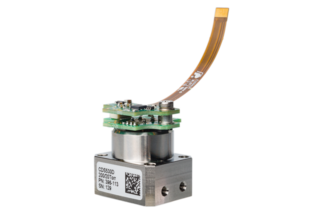

Replaces its crystals automatically without interrupting your process, when partnered with the INFICON IC6 Thin Film Deposition Controller

- Holds 12 crystals with robust, automatic switching to maximize process up-time

- Easy-to-remove carousel allows fast replacement of all 12 crystals

- Stable crystal temperature, because crystal switching is pneumatically-driven (competitive units use heat generating motors)

- Easy-to-remove front deposition shield protects the crystals and carousel from material accumulation, minimizing the need to remove entire sensor for maintenance

On-Site, Decision Quality Data on VOCs in Water

- The only battery-operated insitu purge and trap system for field use with a GC/MS

- Integrated with the HAPSITE data system

- Modular, low-maintenance design for rugged environments

- Unique, robust purge and trap system for the most difficult applications

identify an Expanded Range of Chemicals in Hard to Reach or Dangerous Environments

- Fast sampling using SPME Survey

- Enhanced HAPSITE ER performance with low volatility compounds including V-agents and explosive taggants

- Increased portability and mobility

- Numerous fibers can be brought to the field for sampling and analyzed at a central location

trace Level Quantitative VOC Analysis

- Quickly analyzes samples collected from remote locations

- Intrinsically safe sampling pump samples can be collected in potentially explosive environments

- Optional person-portable sample pump can be worn for breathing zone monitoring

- TD Survey analytes can be sent directly to the mass spectrometer, by-passing the gas chromatograph, for chemical identification in minutes

Performs Soil and Water Analysis On-Site, Decision-Quality Data On VOCs In Water, Wastewater, Soils And Solid Wastes

- The only battery-operated headspace sampler for field use

- Results comparable to EPA method 8260

- Convenient inlet system for analyzing soil, water, and solid samples

- Integrated with the HAPSITE data system

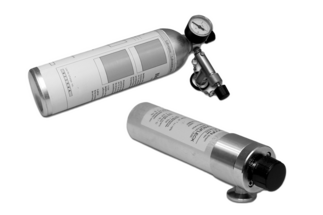

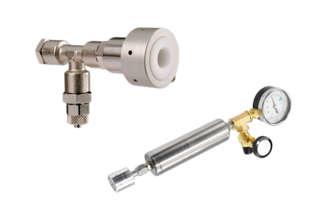

support functions for all HAPSITE Chemical Identification System models

- Used to replace NEG on-site with guidance from an INFICON Service representative

- Used as an alternative or backup method to using a NEG to provide vacuum for HAPSITE (i.e. when the NEG is not installed or is being serviced)

- Used to perform HAPSITE troubleshooting operations with guidance from an INFICON Service Representative

- Used an alternate power source for HAPSITE

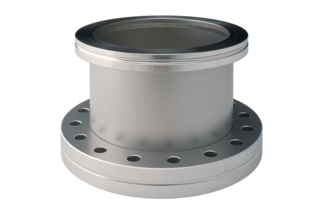

- DN 63 ISO-K/DN 63 CF

- DN 100 ISO-K/DN 100 CF

- DN 160 ISO-K/DN 160 CF

- DN10-DN50

Real-Time, in situ process monitoring, prevent over-etching, identify chamber clean end point

- Real-Time, in situ process monitoring

- Prevent over-etching, identify chamber clean end point

- Identify equipment or process state fault

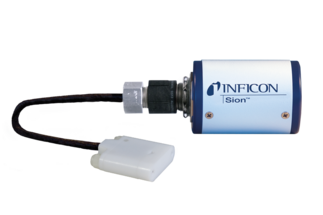

SemiQCM™ SR sensor is one component of a system for precursor monitoring with the other components being an IMM-200 and FabGuard (version 19.12.00-a or higher).

- Real-Time, in situ process monitoring

- Prevent over-etching, identify chamber clean end point

- Identify equipment or process state fault

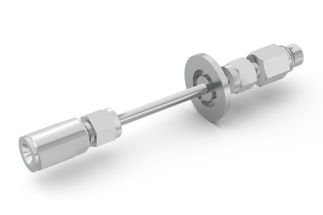

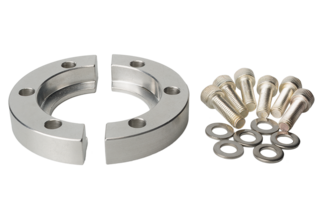

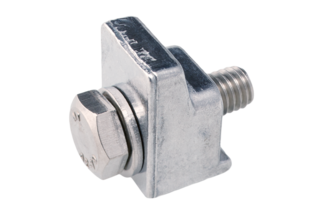

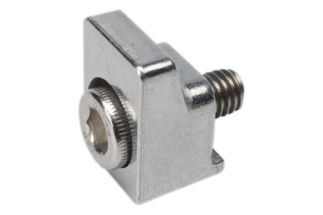

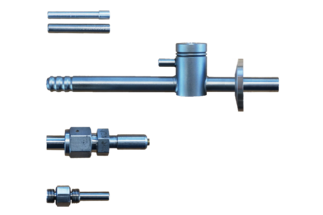

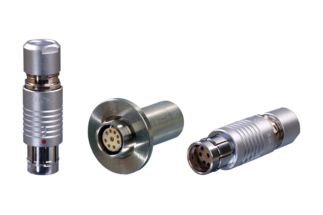

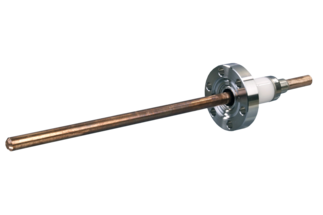

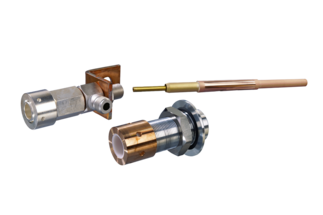

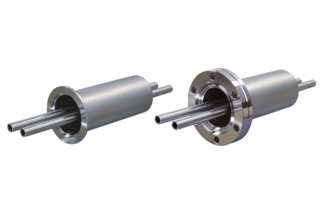

2.54 cm (1 in.) bolt or CF40 (2.75 in. ConFlat®) styles available, available with bored-through tube fittings

- 2.54 cm (1 in.) bolt or CF40 (2.75 in. ConFlat®) styles available

- Available with bored-through tube fittings

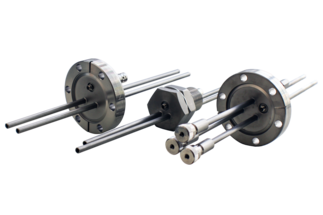

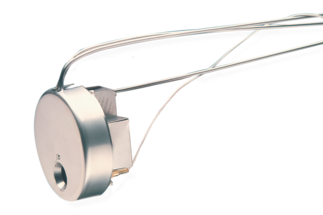

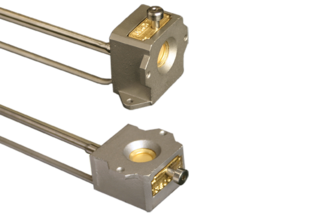

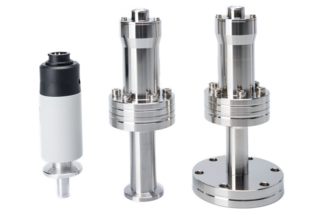

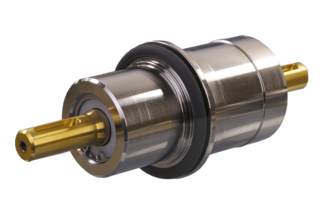

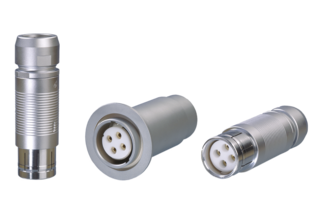

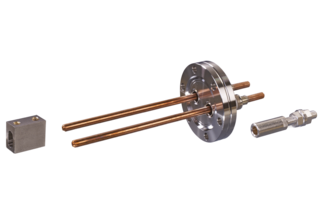

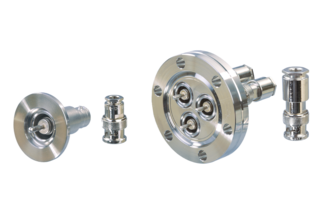

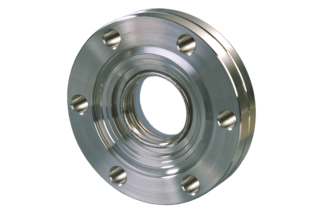

Variety of Quartz Crystal Monitor (QCM) sensor feedthroughs to accommodate many QCM sensor and chamber configurations

- 2.54 cm (1 in.) bolt or CF40 (2.75 in. ConFlat®) styles available

- Available Ultra-Torr O-ring compression fittings

- Custom feedthrough configurations available

- Other feedthrough styles available on request

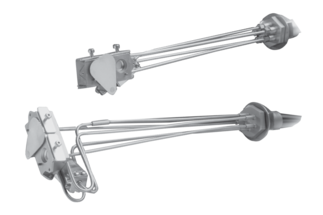

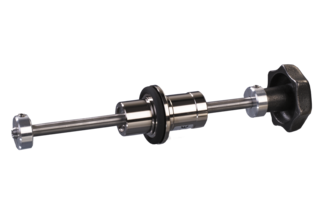

designed for demanding processes, employing very thick films and several different materials

- Six crystals

- Position feedback (Controller dependent)

- Adjustable length (with optional flange)

- Rugged design

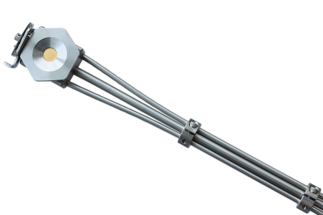

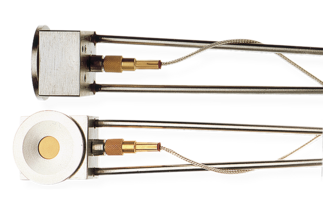

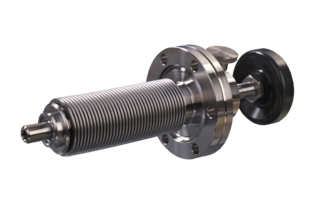

CrystalSix Sensor is critical for long processes demanding continuous rate control

- Holds 6 crystals with robust, automatic switching to maximize process uptime

- Stable crystal temperature, because crystal switching is pneumatically-driven (competitive units use heat-generating motors)

- 1/8" tubes maintain thermal stability and allow flexibility in sensor placement

- Optional crystal shutter available

designed for use in any sputtering process

- Gold plated beryllium copper sensor body and cooling tubes for maximum cooling efficiency

- Magnet to deflect free electrons away from the monitor crystal

- Easy installation with bendable water tubes allowing flexibility in sensor placement

- Rear load crystal insertion for easy crystal replacement

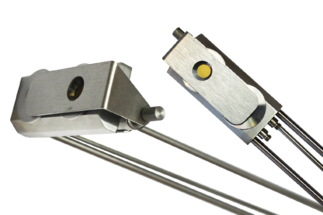

repeatability, precision, and durability of quartz crystal microbalance (QCM) measurement to atomic layer deposition (ALD)

- Operating temperature up to 450°C

- Gas purge line keeps back of crystal free of depsotion material

- Welded Conflat flange (CF40) option

- O-ring compression fitting option

offer proven reliability and durability and have the best thermal stability of any sensor head on the market

- High temperature braze & welded construction

- Bakeout temperatures to 450° C

- Crystal shutter (option)

- Front load crystal holder

simple and inexpensive solution for QCM applications where one crystal may not be enough

- Dual crystals

- Low in price, high in quality

- Front load crystal holder

- Includes crystal shutter

designed for use in critical processes where it is desirable to have a second crystal in the vacuum chamber

- Dual crystals

- Cool Drawer crystal holder

- No internal cables

- Crystal shutter

allow crystal installation into the sensor from the side, convenient for systems with insufficient room for front load crystal installation

- No internal cables

- Cool Drawer crystal holder

- Easy installation

- Bakeable if ordered with welded CF40 flange

proven reliability and durability

- Dual crystals

- Crystal shutter

- Front load crystal holder

- Easy installation

Proven reliability and durability and the best thermal stability of any sensor head on the market.

- Front load crystal holder

- Easy installation

- Available with 2.54 cm (1 inch) bolt feedthrough / CF40 Feedthrough

- Adjustable length if ordererd with compression fittings

cost effective solution to high-accuracy thickness monitoring for short optical and batch coating processes

- Minimum investment with lowest upfront cost

- Lowest total cost of ownership from extended sensor life

- Maximum throughput with less maintenance

- Easy installation

Combines the simplicity of USB connectivity with the accuracy of a precision measurement engine, all in a compact, inexpensive package

- Low cost deposition monitor

- USB connection

- Internal oscillator

- High accuracy at 10 measurements per second

Multi-Film Rate / Thickness Monitor with averaged sensor control capability for large systems or assigned sensor inputs for different materials

- Two measurement channels standard, an additional four optional

- Analog outputs for rate/thickness recording

- High resolution option: 0.03Hz at 10 readings/sec

- RS-232 standard, USB or Ethernet optional

Compact deposition monitor built with ModeLock technology to maximize reproducibility and uniformity with the highest thickness accuracy, best measurement resolution, and lowest rate noise

- INFICON ModeLock technology provides the longest crystal life and ensures the most stable, highest resolution rate and thickness measurement available, even at very low rates

- Maximize yield with the best QCM thickness measurement possible

- Single channel rate and thickness monitor without unnecessary added features to compact size and minimize cost

- Ethernet communications for seamless integration

Compact deposition monitor built with ModeLock technology to maximize reproducibility and uniformity with the highest thickness accuracy, best measurement resolution, and lowest rate noise

- INFICON ModeLock technology provides the longest crystal life and ensures the most stable, highest resolution rate and thickness measurement available, even at very low rates

- Maximize yield with the best QCM thickness measurement possible

- Single channel rate and thickness monitor without unnecessary added features to compact size and minimize cost

- EtherCAT communications for seamless integration

Simultaneous Control of Up to Eight Materials using Electron Impact Emission Spectroscopy

- Monitor and control simultaneous deposition of up to 8 materials

- Deposition rates from 0.1 to 10,000 Å/s

- Integrated EIES and QCM thin film process control

- 12 relay outputs and 12 digital inputs

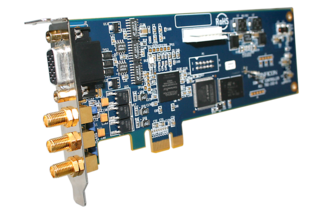

Low-Cost Deposition Control on a PCI Express Card

- PCI Express, install multiple cards in a PC

- Three sensor inputs, three control outputs per card

- Easy PLC integration to add I/O capabilities

- Codeposition of multiple sources

Highly Accurate Sequential or Codeposition Control

- Bright, color LCD display - available in English or Chinese

- Standard RS-232 and USB (RS-232 and Ethernet optional)

- Easy setup and operation with a "Quick Setup" Menu, 6 context-sensitive push buttons, and convenient parameter setting knob

- Windows® program for developing, testing, and downloading processes, and for logging instrument data to your PC for process analysis and quality control

Advanced, Affordable Rate Control for Single and Multiple Layer Processes

- Available in single-layer and multiple-layer models

- Patented ModeLock technology prevents film thickness errors caused by mode-hopping

- Supports INFICON Crystal 12®, Crystal Six®, and dual sensor automatic crystal switching for maximum productivity

- XTC/3M multiple-layer model supports up to 99 processes, 999 layers, 32 films, 2 sensors, and two sources

Provides exceptional value by combining the proven performance of INFICON thin film controllers with unique features, all designed for you to achieve the most from your OLED process

- INFICON ModeLock technology ensures the most stable, highest resolution rate and thickness measurement available, even at very low rates

- Auto Z improves thickness accuracy by automatically determining the Z-ratio as material is deposited

- Up to six sources can be controlled simultaneously, independently or in any combination by one Cygnus 2, relieving the need for two or three controllers

- USB data storage for screen shots, recipe storage, and data logging

Provides exceptional value by combining the best performance, quality, and features of any other quartz crystal controller

- INFICON ModeLock technology ensures the most stable, highest resolution rate and thickness measurement available, even at very low rates

- Auto Z improves thickness accuracy by automatically determining the Z-ratio as material is deposited

- Codeposition of up to six sources simultaneously

- USB data storage for screen shots, recipe storage, and data logging

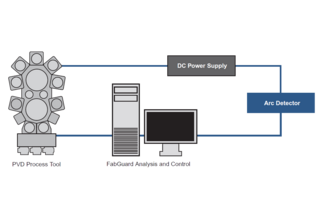

Non- Invasive, high speed, DC arc dection for real-time process control

- Software integration to the tool through FabGuard Sensor Integration and Analysis System

- Data collection at 250 kHz per channel

- Custom cables connect to most DC generators

- Detects arcs quickly with pre-defined analysis tools

Non-Invasive, Clamp-On RF Detector Delivers High-Speed Arc Detection and Clean End Point Control for higher yields and reduced Cost of Ownership

- Easy retrofit to existing tool set and drop-in replacement for OES-based instrument for endpoint control

- Non-invasive sensor installation

- High-speed data collection (250 kHz) for arc detection

- Eliminates chamber clean under- and over-etching, increasing uptime and reducing cost of gas usage and materials

- Integrated data management with FabGuard

Quartz crystals are needed to monitor deposition rate in situ, collect accurate measurement data, and provide a means to analyze research applications.

- Maximize process performance with quality, reliability, and support

- Diminish Process Risk with a wide array of electrode material choices for compatibility to liquid and gas processes

- Each crystal is tested and inspected to ensure quality and the highest accuracy and reliability

- Obtain knowledgeable and personalized support for your unique application

100% Tested for Accuracy and Reliability and needed to monitor deposition rate in situ, collect accurate measurement data, optimize PVD applications, and to automate the process when coupled with a thin film controller.

- Increase profitability and maximize continuous process runs with increased production time

- Minimize cost of consumables with the highest quality crystals to ensure maximum crystal life

- Optimize inventory management with flexible delivery schedules and in stock products

- Maximize process performance and gain customized solutions with worldwide applications support

GC-based system that autonomously samples VOCs in water, quantifies contaminant levels and automatically alerts users if thresholds are exceeded

- Saves labor and money with autonomous testing

- Reduces frequency of regular outside lab analysis

- Lowest cost of ownership

- Less wasted time with limited maintenance and no sample prep

the only person-portable GC/MS that identifies VOCs and SVOCs. Quick, Easy, Accurate On-Site Performance

- Fast, confirmatory results in the field directly comparable to laboratory GC/MS data

- Universal interface allows for accessory expansion without a hardware change to HAPSITE

- Simple operation for even basic skill levels with minimal training

- Visual confirmation of correct probe placement for optimum sample collection

Delivers accurate, lab-quality results in minutes to make threat assessments, and decisions with confidence

- Sensitivity/trace level identification

- Expanded mass range/narcotic and FGA/A-series detection

- Cartridge concentrator/portable collection

- Intuitive, easy-to-use software/minimal training

- Optimized sample path/reproducible and quantifiable data

The intelligent helium spray-gun for all leak detectors of the UL Family

- Portable, wire- and hoseless helium spray gun

- Flexible and efficient leak testing

- Integrated color display

- USB-C charging port and replaceable battery

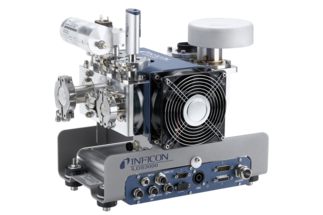

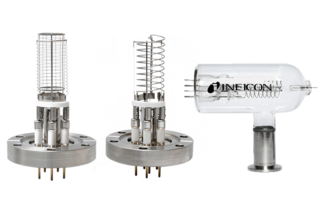

High performance quadrupole mass spectrometer

- Nine-decade dynamic range

- Industry leading data collection rate

- Interchangeable sensors and electronics

- Scans up to 300 amu

Analyzing Tool States and Idle Time to Identify Capacity Bottlenecks

- Designed for all levels of management

- Easily extract MES data for reporting

- 165+ Predefined reports and highly configurable

- No code business intelligence tool

Most advanced digital Pirani technology, compact size and the variety of features.

- Available with Tungsten (PSG550) or Nickel (PSG552) filament or with a fully ceramic coated (PSG554) sensor unit for highly corrosive applications

- Optional display, setpoints and digital interfaces

- Latest EtherCAT protocol Standard ETG.5003.2080 S (R) V1.3.0

- Easy to exchange plug & play sensor element with on-board calibration data - guarantees high reproducibility and low cost of ownership

Reliable measurement of refrigerant transfers in a durable, wireless package.

- Displays real-time readings on your smartphone or tablet or through an optional wireless handpiece

- Alarm mode makes charging or recovering easier

- Measures in lb., lb./oz., oz., or kg,

- Rugged aluminum platform for superior durability

- DN10-DN40

Multi-Purpose Quadrupole Mass Spectrometer

- Nine-decade dynamic range

- Interchangeable sensors and electronics

- Optional continuous dynode electron multiplier

- Scans up to 200 amu

Pirani Capacitance Diaphragm Gauge combines Pirani sensor and ceramic capacitance diaphragm sensor in one product

- Gas type independent above 10 mbar

- High accuracy and reproducibility at atmosphere

- Versatile of mounting orientation

- Optional with Nickel (PCG552) filament or with ceramic coated (PCG554) sensor for highly corrosive applications

The ultimate in mobile vacuum leak detection designed to meet the most critical and demanding leak detection applications and in particular large volumes

- Fastest mobile vacuum leak detector

- Most reliable leak detection

- Most robust vacuum system

- Slim & easy to manouver

- Intuitive control & Easy to use

Versatile process monitoring from baseline to process pressure

- Ideal semiconductor process monitor

- Multi pressure sampling inlet

- Detection limit below 1 ppm

- Integrated differential pumping

Compact Process Expert for Advanced Process Monitoring

- HexBlock multi-pressure sampling inlet

- Detection limit below 200 ppb

- Industry leading pumping speed

- 30% decrease in system volume

Factory Scheduler utilizes Advanced Heuristics, Linear Programming, Optimization, and Intelligent Search Algorithms to generate a real-time optimized schedule that can be easily tuned to meet your manufacturing needs.

- Calculates and conduct a full schedule of lots running on tools

- Comprehends area-specific constraints and objectives

- Manages queue timers, maintenance windows, cluster tools, etc.

Industry-leading recovery rates even in the hottest conditions.

- 1 HP dual piston compressor for industry leading recovery rates

- Micro-channel condenser provides exceptional heat exchange to sustain maximum recovery rates

- Oversize fan provides exceptional cooling

- Simple two valve operation

- DN10-DN40

Inverted Magnetron Vacuum Gauge is the workhorse for all vacuum measurement applications. Measurement range from 1x10-9 mbar to atmosphere.

- Long lifetime in harsh environments

- Low magnetic stray field

- Reliable fast ignition

- Fastest maintenance - replaceable insert

Designed for the needs of leak checking in semiconductor applications

- Save time with I·CAL software algorithm for fast measurements in the range of 10-9 to 10-12 mbar·l/s

- Most efficient leak checking using I·ZERO 2.0

- Applicable for vacuum and sniffer leak search

- Minimize leak checking efforts through quick evacuation and response time

Process monitoring at target pressure range

- Targeted high pressure processes

- Single pressure sampling inlet

- Detection limit below 1 ppm

- Integrated differential pumping system

Provides straightforward instructions to operators and material handlers on the factory floor.

- Integrates the optimal lot level solutions created by the FPS Scheduler

- Visual aides to inform Operators when the tools in their area will go idle

- Directs material handlers to get the lots to the right place at the right time to ensure optimal tool utilization

Two-stage rotary vane 5 CFM pump for ultimate vacuum down to 15 microns.

- 5 CFM displacement

- 2-stage rotary vane pump with 1/2 HP motor

- Gas ballast for faster pumping and fewer oil changes

- Dual voltage operation

- DN10-DN50

Inverted Magnetron Pirani Gauges, measure from 5 x 10-9 mbar to atmosphere

- Combination gauge – Inverted Magnetron & Pirani

- Wide measurement range from 5 x 10-9 mbar to atmosphere

- No filament to burn out

- Excellent ignition properties

renowned standard when it comes to economic helium vacuum leak testing in industrial or semiconductor environments

- minimize leak testing efforts through quick pump down and response time

- avoid need for multiple leak tests by using selectable background suppression (iZERO)

- enable easy access to maintenance areas with restricted space through maneuverable design

- low total cost of ownership (TCO) enabled by robust two hot filament ion source (3 years warranty) and counterflow vacuum system

QMG 700 Analytical Mass Spectrometer to break through detection barriers and propel your process to the next level of innovation

- Mass range options from 1-512 amu

- More than nine decades of dynamic range

- Extremely fast measurement speeds: 0.125 ms/amu

- MDPP < 10E-16 mbar

Enhancing Tool Dispatching Efficiency

- Industry standard dispatch rules

- Improve delivery and report on performance

- Easy to use

- DN10-DN50

Superior accuracy, filter-protected sensor, and provide more jobsite productivity.

- Measures from atmosphere to 1 micron

- Innovative filter protects sensor to reduce the need for cleaning

- Auto shut-off after 60 minutes to conserve battery

- Pirani sensor for better accuracy

Inverted Magnetron Vacuum Gauge is for all ultra high vacuum applications, measurement range from 5x10-11 mbar

- Measurement range down to 5x10-11 mbar

- Extended version, sensor bakeout up to 250°C

- Excellent ignition properties

- Easy to clean

Provide fast real-time leak detection, gas analysis, and process monitoring for semiconductor manufacturing and other markets.

- High speed leak detection allows chamber leak test

- Smart algorithm for easy integration

- Long life time, no filament burns, air inrush protection

- Withstand process chemistry

Leverage the historical operational data in the Digital Twin to create previously unavailable insight into Cycle Time losses.

- Easy to navigate cycle time website available to anyone on the company intranet.

- The individual components of cycle time (queue time, process time, post process time) are broken down visually.

- Components of cycle time can be compared by product, by module, or by step within the product flow.

- Charts showing average WIP levels allow you to see the interactions between WIP and cycle time.

- DN10-DN40

New levels of productivity and reliability to the final leak testing of refrigerators, freezers, automotive air conditoners and similar products.

- Improved system design compensates for poor sniffing operation reducing the potential for missed leaks.

- IGS (Interfering Gas Suppression) ensures only leaks are detected.

- Built-in ECO-Check reference leak allows for easy and fast calibration at the production line at any time.

- Multiple alarms make sure leaks can not be overlooked.

Portable, easy-to-use refrigerant identification

- Identifies purity of R1234yf and R134a

- SAE or VDA test modes

- Sample vapor from cylinders or vehicles

- SAE J2912 approved

Single Bayard Alpert sensor, measurement range from 5×10-10 mbar to 2.7×10-2 mbar, Excellent repeatability

- Measurement range from 5×10-10 mbar to 2.7×10-2 mbar (3.75×10-10 Torr to 5×10-2 Torr)

- Excellent repeatability in the process pressure range from 10-8 … 10-2 mbar of 5%

- Overpressure detection protects the filament from premature burnout

- Two long-life yttrium oxide coated iridium filaments

Specifically designed for full-time sniffing applications in demanding production Environments.

- I-Guide operator guiding mode ensures your operator is testing the right locations with the correct technique.

- Improved system design compensates for operator error reducing the potential for missed leaks.

- Multiple alarm functions make sure alarms can not be overlooked.

- Built-in PRO-Check reference leak allows for easy and fast calibration at the production line at any time.

Provide real-time leak detection, endpoint detection and process monitoring for cutting-edge semiconductor manufacturing processes and other gas analysis applications

- Operating range from 1 Torr up to 450 Torr

- Superior detection limit < 1 ppm

- Long-term reliability: no pumps required

- Easy installation using a standard KF25 connection

Creates estimates of tool utilization for given starts profiles using precise factory data.

- Enhanced material movement modeling

- Granular cycle time contributions by product, by module, or by step within the product flow

- DN10-DN50

Reliable, integrated refrigerant identification for RRR machines

- SAE or VDA output

- Typical five year O2 sensor

- SAE J2927 approved

- One unit detects both R134a and R1234yf

ATM to Ultra High Vacuum hot cathode gauge

Drop in compatible to other manufacturers PBR 260 Pirani/Bayard-Alpert hot cathode gauges

- Partnumber IGG27000 matches

PT R27 000 - Partnumber IGG27001 matches

PT R27 001 - Partnumber IGG27002 matches

PT R27 002

Bayard-Alpert Pirani Combination Gauge, single hot ion filament

- Extremely wide measurement range from 5×10-10 mbar to atmosphere

- Excellent repeatability in the process pressure range

- The Pirani interlock protects the Bayard-Alpert system from premature filament burnout

- Long-life yttrium oxide coated iridium filament

Provide real-time leak detection and endpoint detection for critical process environments

- Operating range of 10 mTorr to 1 Torr

- Excellent detection limits down to low ppm levels

- Long-term reliability: no pumps required

- Easy installation using a standard KF25 connection

Optimally assign team members in the factory based upon current and future workloads.

- Automatically determines the optimal assignment of shift team members

- Consider certifications and skill sets

- Capture historical operating staffing and performance

- Provide critical real-time visualization of staffing

- DN10-DN50

Functions as two gauges in a single compact unit measuring from 5×10-10 mbar to atmosphere.

- Extremely wide measurement range from 5×10-10 mbar to atmosphere

- Two long-life yttrium oxide coated iridium filaments

- Excellent repeatability in the process pressure range

- Pirani interlock protects the filament from premature burnout

Inline leak testing for the mass production of battery cells

- Inline leak testing for the mass production of battery cells

- Direct electrolyte leak testing of all metal-ion battery formats

- Unmatched measurement reliability - no leak is missed

- Easy integration into high-speed production systems

- Maximum efficiency with multi chamber connection for the targeted throughput

Optimize your combustion efficiency

- Displays efficiency, O2, CO2, CO and flue gas temperature readings all on one screen

- Easy-to-read backlit display

- Monitor system pressures with built-in manometer and hose kit

- QR code for quick analysis reports using the FLUE-Mate mobile app

Supporting the Autonomous Driving Zero Defect Challenge - World’s First Smart Integrated Sampling Management System

- User defined rule set to manage sampling objectives

- Integrates with clients MES and tags inventory

- Minimize the amount of material being measured while maintaining coverage and managing excursions

- DN10-DN50

Bayard-Alpert Pirani Capacitance Diaphragm Gauge (TripleGauge®), BCG450, combines the advantages of three different technologies in a single, compact, economical package to measure process and base pressure from 5×10-10 to 1500 mbar (3.75×10-10 to 1125 Torr)

- Pirani, Bayard-Alpert and CDG sensors in one gauge

- Gas-type-independent pressure measurement above 10 Torr

- Pirani interlock protects the hot filament from premature burnout

- Automatic Pirani adjustment reduces operator interventions

With the ELT3000 PLUS Battery Electrolyte Leak Detector, INFICON offers a unique, non-destructive leak testing solution for all Lithium-ion battery cells, including fragile pouch cells.

- Direct electrolyte leak testing of all lithium and sodium-ion battery formats

- Unmatched measurement reliability - no leak is missed

- Maximum efficiency with multi-chamber connection for the targeted throughput

- Quality assurance and longevity due to high sensitivity

Simplify and Accelerate Gas Analysis

- Minimize analysis time

- Maximize availability

- License free access

- Easy connectivity

Predict your factory shipments based on current and historical factory states, broken down by future weeks.

- Model factory output

- Provide supprort for multiple facilities and complicated manufacturing flows

- DN10-DN50

High Pressure Hot Ionization Pirani Gauge, HPG400, combines High Pressure Hot Ionization and Pirani sensors in a single, compact, economical package to measure pressure from 2×10-6 mbar to atmosphere (1.5×10-6 Torr to atmosphere)

- The high pressure hot ion gauge delivers accurate, reliable pressure measurements from 1×10-5 … 1 mbar

- User selectable hot ion emission activation between 5×10-2 and 1 mbar

- Pirani interlock protects the hot filament from premature burnout

Modern leak detector for industrial use

- Handles both small and large leaks, quick reaction - fast recovery, even after large leaks

- Highly sensitive and selective hydrogen sensor - incorporates proven Sensistor sensor technology

- Can detect and locate leaks with a size variation within ten decades

- New color touchscreen and new HMI for easy, more reliable menu navigation

High pressure samples, especially those containing contaminants, such as condensing aerosols, can be harmful to Micro GC Fusion. The External Sample Conditioner, or ESC, provides both a pressure reducing feature while maintaining the sample temperature at >50°C (122°F).

- Easily attaches to Micro GC Fusion

- Side door for easy filter replacement

- Use a quick connect fitting for easy sampling

- Can be taken into the field for on-site sampling

Enhanced Tool Performance (ETP) state logic combines traditional E10 tool centric data with WIP States to provide a comprehensive view of fab operational losses not visible with traditional reporting.

- Detailed state analysis that exceeds the standard E10 Semi state model

- Increased ability to identify manufacturing loss

- DN10-DN50

The portable Extrima Leak Detector is the ultimate intrinsically safe instrument for leak detection in the toughest environments, including hazardous locations such as Zone 0.

- Intrinsically safe for use in hazardous areas (Ex ia IIC T3)

- Up to 7 hours battery operating time -Robust enclosure for demanding field use

- High sensitivity and fast recovery allow for efficient operation

- Low and easy maintenance

Web-based user interface that provides several novel benefits over traditional software.

- Operating system independent

- License-free

- Built with every instrument

- No installation required

- DN10-DN50

Convection enhanced Pirani technology, compact design, higher accuracy

- Wide measurement range and higher accuracy

- Built-in display, 1 set point relay

- Bright digital LED display

- Analog output signals user selectable

Fast, reliable and robust instrument for utilities leak detection such as telecom cables and water pipes

- Quick detection through high and adjustable sensitivity

- Highly selective hydrogen sensor for reliable detection

- Easy to carry and handle

- Quick charging in the car (5 minutes for 20 minutes of operation)

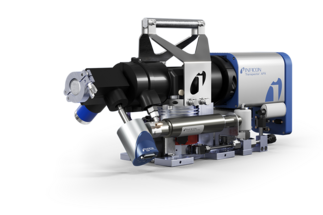

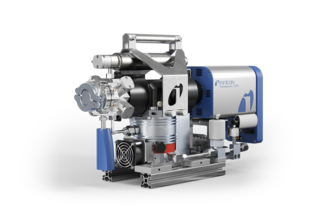

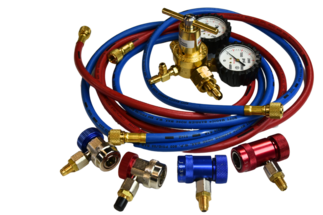

Allows the Transpector CPM to become a mobile troubleshooting instrument

- Flexible enough to get a Transpector CPM where you need it

- A small footprint to fit in those tight spaces

- A complete system able to hold everything needed to run the Transpector CPM

- DN10-DN50

Convection enhanced Pirani technology, with DeviceNet, higher accuracy

- Wide measurement range and higher accuracy near atmosphere

- Digital DeviceNet interface

- Built-in display, 2 set points

- Bright digital OLED display with keypad

User-friendly handling, reproducibility of measuring results and integration into local networks

- Compact, Light And Slim

- Touchscreen Display

- Communicative Diversity

- High Reliability

- DN10-DN50

Convection enhanced Pirani technology, higher accuracy, OLED display, RS485/RS232

- Wide measurement range and higher accuracy near atmosphere

- All-in-One active gauge with 2 set points,

- 4 analog output signals and 2 digital interfaces

- Bright digital OLED display with keypad

- 4 optional analog output signals

Reliable, intelligent and repeatable platform, Optimize your production

- Reliable for maximum uptime

- Intelligent Design improves measurement certainty

- Easy setting of automated procedures

- DN10-DN50

Based on advanced MEMS (Microelctromechanical Systems) sensor technology, Gas type independent above 2 mbar, High accuracy and reproducibility at atmosphere

- Gas type independent above 2 mbar

- High accuracy and reproducibility at atmosphere

- Versatile of mounting orientation

- Selectable analog output signal

T-Guard2 Leak Detection Sensor closes the gap between costly hard vacuum helium leak detection and low sensitivity leak testing methods like waterbath and pressure decay.

- Low operating cost

- No limitation of product properties

- Find all leaks reliably

- Easy to use

- DN10-DN40

Based on advanced MEMS (Microelctromechanical Systems) sensor technology, atmospheric ambient pressure measurement, Gas type independent above 2 mbar

- Gas type independent above 2 mbar

- High accuracy and reproducibility at atmosphere

- Atmospheric ambient pressure measurement

- Up to 3 solid state relays

Cost efficient forming gas or helium for accumulation leak testing, very sensitive and can detect leaks down to the 10-5 mbar∙l/s range

- Cost efficient solution to leak test parts

- Testing as reliable as vacuum chamber - at nearly the cost of air testing

- Ready for the future with fieldbus interfaces for the Industry 4.0 integration

- Temperature and humidty indipendency offers reliable test results with high repeteability

- DN10-DN40

Single Hot Ion gauge, OLED Display, RS485

- Measurement range from 1.3 × 10-9 to 6.7×10-2 mbar

- Two standard long-life yttrium oxide coated iridium filaments

- Set-point, analog output and RS485

- OLED display with keypad

This accessory to Sensistor Sentrac Hydrogen Leak Detector allows you to do automatic leak testing with hydrogen tracer gas

- High reliability for demanding industrial applications

- For semi- or fully automatic leak testing

- Easy to maintain

- Easy sensor change

- DN10-DN50

Innovation makes the difference

- Distinction between natural gas and marsh gas with GC and IR-sensor

- No false alarms, high sensitivity, quick reaction and short recovery time thanks to the integrated proprietary IR-sensor system

- Weatherproof IP54

- Measurements possible even in tough environments thanks to its robust housing

Big performance, small size

- Excellent span stability – gas type independent

- Alumina sensor

- Compact, smallest size in it's class

- Easy integration, any mounting orientation

- DN10-DN50

Industrial application, temperature compensated

- Full scale ranges from 100 mTorr … 1000 Torr

- Fast stability after power on

- Fast recovery from atmospheric pressure

- Corrosion resistant ceramic sensor

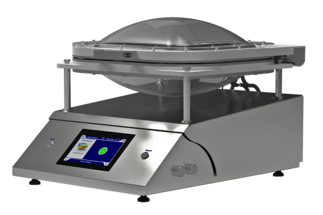

Sustainable and reliable solution for seal inspection in Capsules, MAP- and other types of packaging.

- Maximize shelf life of your packaging

- Avoid customer complaints and dissatisfaction

- Reduce product returns, save money and produce sustainably

- Improve your quality control process

- DN16-DN50

Harsh process application, temperature compensated

- Full scale ranges from 100 mTorr … 1000 Torr

- Fast stability after power on

- Fast recovery from atmospheric pressure

- Corrosion resistant ceramic sensor

Tracer gas filler with complete tooling and gas filling functions

- Complete tooling and gas filling function for high-quality leak detection

- Eliminates the need for time-consuming manual tracer gas filling

- Less operator dependence - full control over all test steps

- Significantly improves test quality assurance

- DN20-DN25

Current loop, temperature compensated

- Full scale ranges from 100 mTorr … 1000 Torr

- Fast stability after power on

- Fast recovery from atmospheric pressure

- Corrosion resistant ceramic sensor

Tracer Gas Filler is a stand-alone instrument which allows for easy and reliable tracer gas filling and evacuating

- Ensured tracer gas filling in the entire test object

- Avoids background contamination

- Made for demanding industrial environments

- Dual port for filling and evacuating for short cycle times

- DN10-DN50

Superior signal stability, temperature controlled

- Lower CoO (cost of ownership), 50% faster warm up, energy efficient low power consumption

- Easy integration, wide variety of full scales, flanges and interfaces, standard with two set points

- Easy one push button or remote signal zero command, zero offset adjustable

- Diagnostic port for quick service and maintenance

Accessory to the Extrima, Ex-certified Hydrogen Leak detector, for injecting tracer gas into fuel leaks during maintenance of aircrafts

- Makes back tracing aircraft fuel leaks controlled and efficient

- Can be operated by one operator

- Includes all you need between the tracer gas bottle and the leak

- Helps keep your detector calibrated

- DN10-DN50

Superior signal stability, temperature controlled

- Lower CoO (cost of ownership), 50% faster warm up, energy efficient low power consumption

- Easy integration, wide variety of full scales, flanges and interfaces, standard with two set points

- Easy one push button or remote signal zero command, zero offset adjustable

- Diagnostic port for quick service and maintenance

Enable to test and to calibrate the helium sniffer leak detector Protec P3000(XL) and XL3000flex for the highest quality demands in leak detection

- Suitable for industrial applications

- Easy to use

- Available in different leak rates

- Inspection certificate included in accordance to DIN EN 10204:2004-3.1

- DN10-DN50

High temperature application, temperature controlled

- Lower CoO (cost of ownership), 50% faster warm up, energy efficient low power consumption

- Easy integration, wide variety of full scales, flanges and interfaces, standard with two set points

- Easy one push button or remote signal zero command, zero offset adjustable

- Diagnostic port for quick service and maintenance

Calibrated test leaks enable to test and to calibrate refrigerant sniffer leak detectors for the highest quality demands in leak detection

- Easy to use

- Suitable for industrial applications

- Available in different leak rates

- Inspection certificate included in accordance to DIN EN 10204:2004-3.1

- DN10-DN50

- DN10-DN50

High temperature application, temperature controlled

- Lower CoO (cost of ownership), 50% faster warm up, energy efficient low power consumption

- Easy integration, wide variety of full scales, flanges and interfaces, standard with two set points

- Easy one push button or remote signal zero command, zero offset adjustable

- Diagnostic port for quick service and maintenance

Calibration test leaks with gas reservoir for vacuum applications

- Inured to pollution

- Metal-free flow reduction for low temperature dependences

- Detemination of the nominal leak rate by comparison with a calibrated leak having a PTB certificate

- Inspection certificate ( included ) in accordance to DIN EN 10204:2004-3-3.1

- DN10-DN50

EtherCAT, temperature compensated

- Easy integration, EtherCAT, wide variety of full scales and flanges, standard with two set points

- Easy one push button or remote signal zero command, zero offset adjustable

- Diagnostic port for quick service and maintenance

- Corrosion resistant ceramic sensor

Calibrated leaks which are capable of meeting the requirements concerning type and required leak rate

- Various types adapted to different customer requirements

- Simple to operate

- Easy to install

- Ideal installations dimensions

- DN10-DN50

Small footprint, temperature controlled

- Compact, saves valuable tool space

- Easy integration, EtherCAT, wide variety of full scales and flanges, standard with two set points

- Easy one push button or remote signal zero command, zero offset adjustable

- Diagnostic port for quick service and maintenance

Calibrated test leaks enable to test and to calibrate refrigerant sniffer leak detectors for the highest quality demands in leak detection

- Suitable for industrial applications

- Easy to use

- Available in different leak rates

- Inspection certificate included in accordance to DIN EN 10204:2004-3.1

- DN10-DN50

Small footprint, temperature controlled

- Compact, saves valuable tool space

- Easy integration, EtherCAT, wide variety of full scales and flanges, standard with two set points

- Easy one push button or remote signal zero command, zero offset adjustable

- Diagnostic port for quick service and maintenance

Cover a wide range of leak rates to suit your specific application and include bigger leaks (Types A-C) and smaller leaks (Types E and G). Leak Type A is intended for accumulation testing only

- Suitable for industrial applications

- Easy to use

- Available in different leak rates

- Traceable to NIST, NMIJ, NPL, PTB, etc.

- DN10-DN50

High speed, temperature controlled

- High productivity – Faster than 2 ms response time (FS > 50 mTorr)

- Flexible integration – EtherCAT fieldbus

- Long lifetime – Proven ceramic sensor

- Forget recalibration – 90 ppm/year full scale stability

Superior sensitivity and interchangeable sensors for maximum versatility.

- New, redesigned infrared sensor with easy field replacement

- Quick charge lithium ion battery

- Detects CFCs, HCFCs, HFCs, HFOs, blends (including A2Ls), CO2*, and flammables*

- DN10-DN50

High speed, temperature controlled

- High productivity – Faster than 2 ms response time

- Flexible integration – EtherCAT fieldbus

- Long lifetime – Proven ceramic sensor

- Forget recalibration – 90 ppm/year full scale stability

Cloud hunting PPM display, superior sensitivity, and interchangeable sensors for maximum versatility.

- Innovative cloud hunter mode with ppm helps locate leaks faster than ever

- New, redesigned infrared sensor with easy field replacement

- Quick charge lithium ion battery

- Detects CFCs, HCFCs, HFCs, HFOs, blends (including A2Ls), CO2*, and flammables*

- DN10-DN50

The reference, true high precision

- True high precision pressure measurement – Ceramic technology

- Full stable output – Proven by PTB

- Flexible communication – Various modern interfaces

- All functions integrated – No controller required

Large, easy-to-read LCD display can not only pinpoint the leak location, but help quantify the leak size using the PPM reading.

- Detects R134a, R1234yf, and all HFCs, HFOs, and blends

- Meets all SAE standards for automotive AC leak detection

- Infrared sensor minimizes false alarms from common under-hood chemicals

- PPM and pinpoint modes help find leaks faster

- DN10-DN50

Miniature sensor for OEM

- The miniature sensor offers a high accuracy

- Excellent repeatability and long-term stability

- Weldable feedthrough for custom integration and calibration, or welded custom flange for integration of factory calibrated sensor

Heated diode sensor for fewer false alarms with rechargeable convenience.

- Heated diode sensor provides excellent sensitivity

- Detects CFCs, HCFCs, HFCs, HFOs, and blends (including A2Ls)

- Rechargeable battery

- Easy one button operation

- DN10-DN50

Miniature sensor for OEM, dual sensor

- The dual miniature sensor offers a high accuracy in a wide measurement range

- Wide range, high precision

- Excellent repeatability and long-term stability

- Sensor electronics with SPI interface for easy integration

Easy operation and heated diode sensor for fewer false alarms.

- Heated diode sensor provides excellent sensitivity

- Detects CFCs, HCFCs, HFCs, HFOs, and blends (including A2Ls)

- Runs on two D-cell batteries

- Easy one button operation

- DN10-DN50

Differential to Ambient - Safety switch for vacuum systems

- Reliable and budget-priced vacuum switch

- High life time

- Rugged design

- Easy to integrate

Infrared sensor for fewer false alarms and superior sensitivity.

- Detects R-134a, R-1234yf, and all HFCs, HFOs, and blends

- Meets all SAE standards for automotive AC leak detection

- Infrared sensor minimizes false alarms from common under-hood chemicals

- Compatible with optional CO2 sensor

- DN10-DN50

Absolute pressure switch with a adjustable electrical switching contact

- High switching accuracy (± 0.1 mbar)

- Stable long term operating characteristics

- Rugged, corrosion protected design

- Switching contacts (normally closed) in the reference chamber and thus protected against process media

Simple operation and proven heated diode sensor for reliable leak checking.

- Sensitivity of 2 g/a (per EN 14624)

- Detects R134a, R1234yf, and all HFCs, HFOs, and blends

- Fewer false alarms than standard automotive leak detectors

- Runs on two D-cell batteries

- DN10-DN50

Absolute Switch - Accurate and reliable pressure detection

- IP 44 protection

- Relay output with potential free contacts

- High-accuracy temperature compensated sensor

- Application pressure range 1×10-9 mbar … 2 bar

Safe and easy leak checking using hydrogen forming gas.

- Detects forming and combustible gases

- 7 g (0.25 oz.)/year sensitivity to forming gas (R134a equivalent)

- Intrinsically safe

- Runs on two D-cell batteries

- DN10-DN40

Differential Switch - Accurate and reliable pressure detection

- Corrosion resistant all stainless steel design

- Robust design, cleanroom compliant

- Easy installation with setpoints factory preset or field-adjustable

- High-accuracy temperature compensated sensor

Compact reference leak source that continuously leaks R134a, R1234yf, or R600a refrigerant for over 2 years

- Available for R134a, R1234yf, or R600a

- Compact size easily fits in your leak detector carrying case

- Easy-to-use

- No batteries required

- DN10-DN50

Sustainable solution for process measurement, control and data log.

- Simple operation with dot matrix menu guided display for parameter, sensor or general settings

- Very bright and clear Display for long distance Instrument read- out

- Bar graph display with setpoints's or pressure vs. time display

Simple, reliable and safe solutions for standalone constant monitoring of larger areas for most refrigerant gases.

- Detects all CFCs, HFCs, HCFCs, and HFOs

- Works with up to 6 remote sensors

- Low maintenance, single point calibration

- Three adjustable alarm setpoints

VGC094 is a prestigious solution for vacuum process measurement, control and data log.

- Complete solution for vacuum monitoring and control monitor from 1×10-11 to 1000 mbar, even at long distance

- Bright and clear screen

- Bar graph display with set-point or pressure vs. time views

- Simple sensor operation with intuitive and guided menus for parameter, sensor or general settings

- DN16-DN40

Simple, reliable and safe solutions for standalone constant monitoring of any refrigerant gas.

- Detects all CFCs, HFCs, HCFCs, HFOs, and HCs

- Remote and integrated sensor options

- Low maintenance, single-point calibrations

- Three adjustable alarm setpoints

- DN10-DN40

Pirani passive gauge heads for VGC094

- Elastomer (PSG010) or metal-sealed (PSG017, PSG018) design

- Specified high measurement accuracy and repeatability

- Bake-out temperature up to 100 °C (PSG010) / 250 °C (PSG017, PSG018)

- Ionizing radiation resistant up to 106 Gy (PSG017, PSG018)

Versatility and flexibility for a variety of applications.

- Verstility for a variety of applications and industries

- Works on any gas under pressure or vacuum

- Hear the leak using the included headphones

- Laser pointer makes it easier to pinpoint the leak

- DN10-DN50

The Pirani Gauge Enhanced 050 (PGE050) is the passive version of our active convection enhanced Pirani gauges PGE300 and PGE500.

- Convection enhanced Pirani technology for wide measurement range and higher accuracy near atmosphere

- Gold plated tungsten filament

- Mechanical robust and less susceptible to mechanical shock and vibration

- Large choice of flange options

Safely detect flammable refrigerant and combustible gas leaks.

- Sensitive to 5 ppm methane

- Also detects natural gas, forming gas, propane, butane, cyclopentane, ethane, ethanol, isobutane and ammonia

- Great for flammable refrigerants like R290, R600a, and R441a!

- Detects forming gas (95% nitrogen, 5% hydrogen)

- DN16-DN50

Cold cathode passive gauge heads for VGC094 and VGC083C

- Reliable and proven gauge head design, based on the inverted magnetron principle

- Large vacuum pressure measurement range capability from 1×10-11 (MAG070) to 5×10-3 mbar

- Bakeable to 150 °C (MAG050) or 250 °C (MAG060, MAG070)

- Good ignition properties

Convenient and simple operating for easy detection of carbon monoxide hazards.

- Best-in-class accuracy for peace of mind

- Simple operation lets you perform all functions with one hand

- Highly visible, intuitive "stoplight" LEDs and audible alarm give you quick indication of CO hazard

- DN10-DN40

The gauge head MAG084 is a unique magnetic field resistant inverted magnetron cold cathode gauge designed to operate with the Vacuum Gauge Controller VGC094.

- Developed to sustain operation in strong external magnetic fields

- Reliable and proven gauge head design, based on the inverted magnetron principle

- Innovative double ionization chamber principle

- Bakeable to 230 °C

Economical leak detection without the loss of expensive refrigerant.

- Leak check with environmentally friendly N2H2

- Couplers for both R1234yf and R134a systems

- Charges both high and low side of the AC system

- DN10-DN50

Mini hot ion Bayard-Alpert passive gauge head for VGC083

- Long standing, reliable and proven gauge head design

- Drop-in replacement thanks to its compact size, large choice of connection flanges and fittings

- Dual yttrium oxide coated iridium filament cathode assembly

- Electron bombardment (EB) degassing

I-Guide3D 350 Scanner: Maximum Precision for Fully Automated Leak Test Systems

- Automize manual sniffing process regardless variances of joints

- For all tube sizes starting from 1,5mm

- Robot path planning done by software to optimize cycle time

- Become less dependant from workers

- DN16-DN40

Bayard-Alpert passive gauge heads for VGC083

- Long standing, reliable and proven gauge head design

- Drop-in replacement for most nude hot ion gauge heads

- Wide range of emission currents (100 μA to 10 mA)

- Available with single/dual yttrium oxide coated iridium and dual tungsten filament cathode assemblies

- DN16-DN50

Hot cathode ionization passive gauge heads for IM540

- High accuracy of the measurements due to individually calibrated sensing system

- Exchangeable cathode

- Extreme high temperature bake-out up to 400 °C

- DN16-DN40

- DN16-DN50

The new standard of ionization vacuum gauge.

- Developed for applications requiring high measurement accuracy in the high and ultra-high vacuum range

- Electrode system configuration according to ISO/TS 6737

- True pressure for all gas species thanks to predictable relative gas sensitivity with small uncertainty

Advanced controller for process measurement and data recording.

- Easy-to-use dot matrix menu interface for adjusting parameters, sensors or general settings

- Clearly visible and bright display for remote reading of device data

- Bar graph for visualizing setpoints or displaying pressure over time

- DN16-DN50

Cost effective pressure monitoring solution.

- User selectable measurement unit (Pa, mbar or Torr)

- Compact bench top model design can be easily mounted in a panel or 19" rack

- 0 to 10 V output signal from the gauge is available for use in PLC or with a chart recorder

- One free adjustable set point

- DN16-DN50

Three channel controller for passive gauges

- Flexible solution for vacuum pressure monitoring and controlling from atmosphere down to ultra-high vacuum

- Clear and simple operation with three individual bright LED displays

- Parameter, sensor and general settings with softkeys

- DN10-DN50

The Ion Reference gauge Controller IRC081 and its user interface are an operating and display interface to the standardized Ion Reference Gauge IRG080.

- Operating and display solution for accurate vacuum pressure measurement

- User control on all IRG080 gauge parameters set

- Simple manual operation with 5 potentiometers

- User Interface connection via USB-B port to PC

- DN10-DN50

Single channel controller for PGE050

- Display`s and control wide measurement range from 1.3×10-4 up to 1333 mbar

- Bright digital OLED display with keypad for simple set up and Operation

- 4 user selectable analog output signals, 2 set point relays

- RS232/RS485 digital Interface

- DN10-DN40

Versatile hot cathode ionization passive gauge controller

- Supports the operation of the IE414 (Bayard-Alpert) and the IE514 (extractor) hot cathode ionization gauges

- Two active gauges from the PSG5xx (Pirani), PCG55x (Pirani-Capacitance diaphragm) and CDG (Capacitance diaphragm) active gauge lines can be connected and operated

- Simple operation with menu guided display for parameter, sensor or general settings

- DN16-DN40

Connect to INFICON CDG product line to provide a 4 Digit Display

- 4 Digit display for easy read out

- Large 10mm active LED display -

readable from distance and wide range gauge of angle - In-line plug design

- 15pin D-Sub, no extra power connection

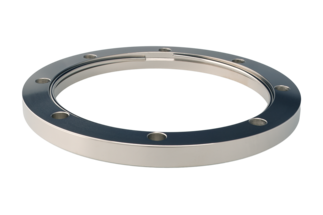

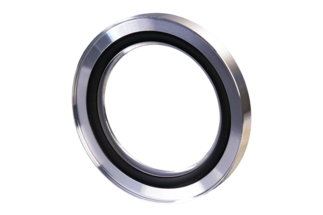

- ISO-KF DN40-DN50/ISO-K DN63

- ISO-KF DN25-DN50/ISO-K DN63-DN100

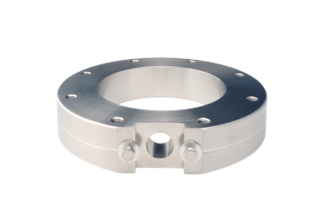

- ISO-KF DN16-DN40/ISO-CF-F DN16-DN100

- ISO-KF DN16-DN40/VCR ¼ in.-¾ in.

- ISO-KF DN16-DN40/VCR ¼ in.-¾ in.

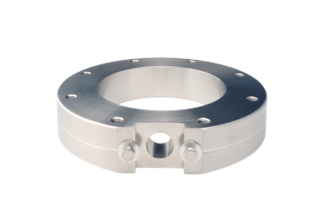

- ISO-KF DN16-DN40

- Swagelok® 6 mm-16 mm / ⅛ in.-½ in.

- DN10-DN40

- DN10-DN40

- DN10-DN40

- DN16-DN40/NPT ⅛"-1"

- DN16-DN40/NPT ⅛"-2"

- DN16-DN40

- DN16-DN40

- DN16-DN40

- DN16-DN40

- DN16-DN40

- DN16-DN40

- DN16-DN40

- DN10-DN20

- DN10-DN50

- DN63-DN630

- DN63-DN630

- DN63-DN630

- DN63-DN630

- DN63-DN630

- DN63-DN1000

- DN63-DN250

- DN63-DN100

- DN63-DN630

- DN63-DN250

- DN63-DN320

- DN63-DN250

- DN63-DN630

- DN63-DN100

- DN160-DN250

- DN63-DN320

- DN63-DN250

- DN63-DN630

- DN63-DN320

- DN63-DN320

- DN160-DN250/DN63-DN200

- DN63-DN250

- DN63-DN160

- DN63-DN250

- DN63

- DN63-DN320

- DN63-DN160

- ISO-K DN160-DN250/ISO-F DN63-DN160

- ISO-K/ISO-CF DN63-DN160

- DN63-DN160

- DN63-DN160

- DN63-DN630

- DN63-DN630

- DN100-DN160

- DN63-DN160

- DN63-DN630

- DN63-DN1000

- DN63-DN1000

- DN16-DN350

- DN16-DN160

- DN16-DN160

- DN16-DN100

- C100

- DN16-DN350

- DN16-DN250

- DN16-DN200

- DN250

- DN16-DN250

- DN16-DN250

- DN16-DN250

- DN16-DN250

- DN16-DN250

- DN16-DN250

- DN16-DN250

- DN16-DN250

- DN16-DN100

- DN40

- DN16-DN160

- DN16-DN160

- DN16-DN160

- DN16-DN160

- DN16-DN160

- DN40-DN63

- DN16-DN160

- DN16-DN160

- DN16-DN160

- DN16-DN160

- DN40-DN160

- DN100

- DN40-DN100

- DN16-DN160

- DN16-DN40

- DN16-DN250

- ISO-KF DN16-DN40

- ISO-K DN63

- DN16-DN40 ISO-CF-F

- FCH DN16-DN40

- FPU DN16-DN40

- DN16 ISO-KF

- DN40 ISO-KF

- DN16 ISO-CF-F

- DN40 ISO-CF-F

- DN40 ISO-KF

- DN16 ISO-KF

- DN16 - 40 ISO-CF-F

- DN40 ISO-KF

- DN40 ISO-CF-F

- DN16-DN50

- DN63-DN160

- DN16-DN160

- DN63-DN160

- 605-6001

- CAF 4

- Apezon M

- Dow Corning

- FU 090

- FM 090

- OL 090

About us

INFICON is a leading provider of advanced technologies and products for the semiconductor, vacuum, and industrial markets. Our product portfolio includes a wide range of innovative solutions that are designed to meet the unique needs of our customers.

One of the key areas we specialize in is leak detection, where we offer a variety of products that can detect and measure leaks in various applications, such as refrigeration and air conditioning systems, industrial gases, and vacuum systems.

Additionally, we also provide gas analysis instruments that can detect and measure various gases, such as halogens, sulfur hexafluoride, and refrigerants.

Furthermore, we also offer advanced vacuum technology products that are used in applications such as research and development, manufacturing, and analytical instrumentation.

In addition to our products, we also offer a comprehensive range of services to support our customers. This includes maintenance, repair, and calibration services, as well as training and education. Our educational content is here to our customers understand the best practices and techniques for using our products, and our team of experienced engineers is always available to provide expert support and guidance.