Thin Film Technology

INFICON’s thin film deposition solutions offer precise control over the creation of ultra-thin material layers, essential for high-accuracy manufacturing processes. Our tools provide real-time feedback, enhancing both efficiency and product quality across industries.

Reset the filters to get results.

Quartz crystals are needed to monitor deposition rate in situ, collect accurate measurement data, and provide a means to analyze research applications.

- Maximize process performance with quality, reliability, and support

- Diminish Process Risk with a wide array of electrode material choices for compatibility to liquid and gas processes

- Each crystal is tested and inspected to ensure quality and the highest accuracy and reliability

- Obtain knowledgeable and personalized support for your unique application

repeatability, precision, and durability of quartz crystal microbalance (QCM) measurement to atomic layer deposition (ALD)

- Operating temperature up to 450°C

- Gas purge line keeps back of crystal free of depsotion material

- Welded Conflat flange (CF40) option

- O-ring compression fitting option

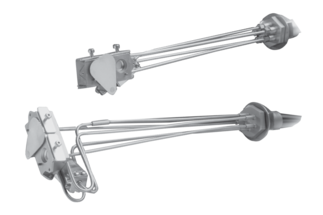

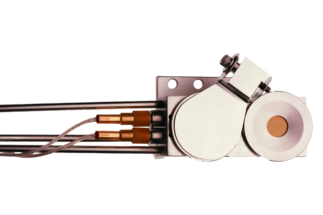

designed for use in critical processes where it is desirable to have a second crystal in the vacuum chamber

- Dual crystals

- Cool Drawer crystal holder

- No internal cables

- Crystal shutter

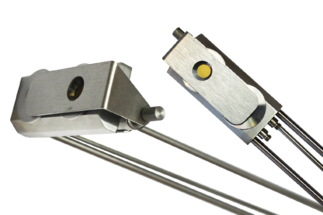

allow crystal installation into the sensor from the side, convenient for systems with insufficient room for front load crystal installation

- No internal cables

- Cool Drawer crystal holder

- Easy installation

- Bakeable if ordered with welded CF40 flange

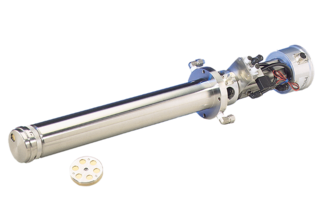

Replaces its crystals automatically without interrupting your process, when partnered with the INFICON IC6 Thin Film Deposition Controller

- Holds 12 crystals with robust, automatic switching to maximize process up-time

- Easy-to-remove carousel allows fast replacement of all 12 crystals

- Stable crystal temperature, because crystal switching is pneumatically-driven (competitive units use heat generating motors)

- Easy-to-remove front deposition shield protects the crystals and carousel from material accumulation, minimizing the need to remove entire sensor for maintenance

CrystalSix Sensor is critical for long processes demanding continuous rate control

- Holds 6 crystals with robust, automatic switching to maximize process uptime

- Stable crystal temperature, because crystal switching is pneumatically-driven (competitive units use heat-generating motors)

- 1/8" tubes maintain thermal stability and allow flexibility in sensor placement

- Optional crystal shutter available

Provides exceptional value by combining the proven performance of INFICON thin film controllers with unique features, all designed for you to achieve the most from your OLED process

- INFICON ModeLock technology ensures the most stable, highest resolution rate and thickness measurement available, even at very low rates

- Auto Z improves thickness accuracy by automatically determining the Z-ratio as material is deposited

- Up to six sources can be controlled simultaneously, independently or in any combination by one Cygnus 2, relieving the need for two or three controllers

- USB data storage for screen shots, recipe storage, and data logging

simple and inexpensive solution for QCM applications where one crystal may not be enough

- Dual crystals

- Low in price, high in quality

- Front load crystal holder

- Includes crystal shutter

2.54 cm (1 in.) bolt or CF40 (2.75 in. ConFlat®) styles available, available with bored-through tube fittings

- 2.54 cm (1 in.) bolt or CF40 (2.75 in. ConFlat®) styles available

- Available with bored-through tube fittings

cost effective solution to high-accuracy thickness monitoring for short optical and batch coating processes

- Minimum investment with lowest upfront cost

- Lowest total cost of ownership from extended sensor life

- Maximum throughput with less maintenance

- Easy installation

proven reliability and durability

- Dual crystals

- Crystal shutter

- Front load crystal holder

- Easy installation

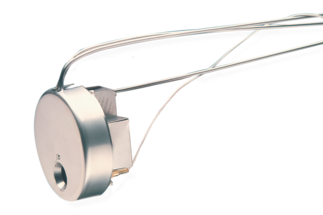

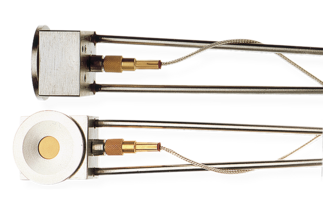

Proven reliability and durability and the best thermal stability of any sensor head on the market.

- Front load crystal holder

- Easy installation

- Available with 2.54 cm (1 inch) bolt feedthrough / CF40 Feedthrough

- Adjustable length if ordererd with compression fittings

Simultaneous Control of Up to Eight Materials using Electron Impact Emission Spectroscopy

- Monitor and control simultaneous deposition of up to 8 materials

- Deposition rates from 0.1 to 10,000 Å/s

- Integrated EIES and QCM thin film process control

- 12 relay outputs and 12 digital inputs

Provides exceptional value by combining the best performance, quality, and features of any other quartz crystal controller

- INFICON ModeLock technology ensures the most stable, highest resolution rate and thickness measurement available, even at very low rates

- Auto Z improves thickness accuracy by automatically determining the Z-ratio as material is deposited

- Codeposition of up to six sources simultaneously

- USB data storage for screen shots, recipe storage, and data logging

Compact deposition monitor built with ModeLock technology to maximize reproducibility and uniformity with the highest thickness accuracy, best measurement resolution, and lowest rate noise

- INFICON ModeLock technology provides the longest crystal life and ensures the most stable, highest resolution rate and thickness measurement available, even at very low rates

- Maximize yield with the best QCM thickness measurement possible

- Single channel rate and thickness monitor without unnecessary added features to compact size and minimize cost

- EtherCAT communications for seamless integration

Compact deposition monitor built with ModeLock technology to maximize reproducibility and uniformity with the highest thickness accuracy, best measurement resolution, and lowest rate noise

- INFICON ModeLock technology provides the longest crystal life and ensures the most stable, highest resolution rate and thickness measurement available, even at very low rates

- Maximize yield with the best QCM thickness measurement possible

- Single channel rate and thickness monitor without unnecessary added features to compact size and minimize cost

- Ethernet communications for seamless integration

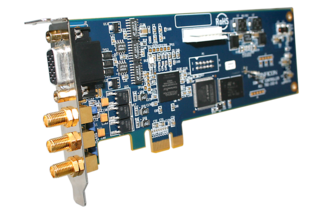

Low-Cost Deposition Control on a PCI Express Card

- PCI Express, install multiple cards in a PC

- Three sensor inputs, three control outputs per card

- Easy PLC integration to add I/O capabilities

- Codeposition of multiple sources

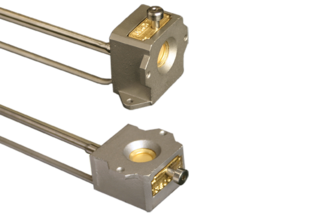

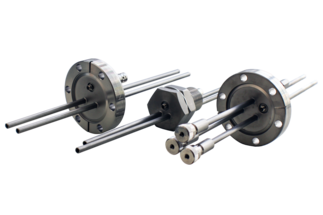

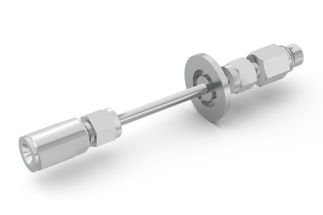

Variety of Quartz Crystal Monitor (QCM) sensor feedthroughs to accommodate many QCM sensor and chamber configurations

- 2.54 cm (1 in.) bolt or CF40 (2.75 in. ConFlat®) styles available

- Available Ultra-Torr O-ring compression fittings

- Custom feedthrough configurations available

- Other feedthrough styles available on request

100% Tested for Accuracy and Reliability and needed to monitor deposition rate in situ, collect accurate measurement data, optimize PVD applications, and to automate the process when coupled with a thin film controller.

- Increase profitability and maximize continuous process runs with increased production time

- Minimize cost of consumables with the highest quality crystals to ensure maximum crystal life

- Optimize inventory management with flexible delivery schedules and in stock products

- Maximize process performance and gain customized solutions with worldwide applications support

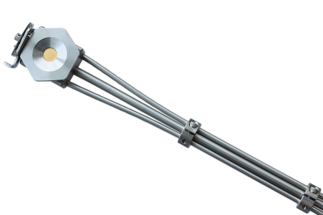

designed for demanding processes, employing very thick films and several different materials

- Six crystals

- Position feedback (Controller dependent)

- Adjustable length (with optional flange)

- Rugged design

Highly Accurate Sequential or Codeposition Control

- Bright, color LCD display - available in English or Chinese

- Standard RS-232 and USB (RS-232 and Ethernet optional)

- Easy setup and operation with a "Quick Setup" Menu, 6 context-sensitive push buttons, and convenient parameter setting knob

- Windows® program for developing, testing, and downloading processes, and for logging instrument data to your PC for process analysis and quality control

Multi-Film Rate / Thickness Monitor with averaged sensor control capability for large systems or assigned sensor inputs for different materials

- Two measurement channels standard, an additional four optional

- Analog outputs for rate/thickness recording

- High resolution option: 0.03Hz at 10 readings/sec

- RS-232 standard, USB or Ethernet optional

Combines the simplicity of USB connectivity with the accuracy of a precision measurement engine, all in a compact, inexpensive package

- Low cost deposition monitor

- USB connection

- Internal oscillator

- High accuracy at 10 measurements per second

Real-Time, in situ process monitoring, prevent over-etching, identify chamber clean end point

- Real-time, in situ process monitoring

- Prevent over-etching, identify chamber clean end point

- Identify equipment or process state fault

SemiQCM™ SR sensor is one component of a system for precursor monitoring with the other components being an IMM-200 and FabGuard (version 19.12.00-a or higher).

- Real-time, in situ process monitoring

- Prevent over-etching, identify chamber clean end point

- Identify equipment or process state fault

offer proven reliability and durability and have the best thermal stability of any sensor head on the market

- High temperature braze & welded construction

- Bakeout temperatures to 450° C

- Crystal shutter (option)

- Front load crystal holder

Advanced, Affordable Rate Control for Single and Multiple Layer Processes

- Available in single-layer and multiple-layer models

- Patented ModeLock technology prevents film thickness errors caused by mode-hopping

- Supports INFICON Crystal 12®, Crystal Six®, and dual sensor automatic crystal switching for maximum productivity

- XTC/3M multiple-layer model supports up to 99 processes, 999 layers, 32 films, 2 sensors, and two sources

Part of the next generation of INFICON Zevision deposition controllers which offer new patented technology needed for today’s optical coaters

- Maximize reproducibility and uniformity with the highest thickness accuracy, best measurement resolution, and lowest rate noise using the ModeLock measurement system

- Maximize number of runs possible while lowering crystal consumable cost with ModeLock

- Minimize integration cost and maximize integration speed

- Minimize development risk and optimize system performance through worldwide expert applications support

Precision Tools for Accurate Thin Film Deposition and Monitoring

Thin film technology plays a critical role in precision manufacturing processes, enabling the deposition of ultra-thin layers of material on a variety of surfaces. INFICON's expertise in thin film deposition provides high-precision solutions that ensure consistent, reliable results for industries that rely on advanced coatings. One of our key tools in these processes is the Quartz Crystal Microbalance (QCM), which monitors deposition rates and ensures precise material layering.

By using INFICON's thin film metrology equipment, manufacturers can achieve full control over the thin film deposition process. These precision measurement tools are designed to maintain the accuracy and consistency that is critical in fields such as semiconductors, optics, and advanced materials. The integration of QCM technology ensures that even the most delicate thin films are applied to exacting standards.

INFICON's suite of tools not only improves thin film deposition, but also provides real-time feedback, making it easier to adjust parameters on the fly. This results in increased efficiency, reduced waste and improved product quality, solidifying our commitment to advancing thin film technology solutions.