Sensors & Feedthroughs

Gain accurate, reliable measurement and control for thin film deposition processes in display, solar, optical, semiconductor, aerospace, and industrial applications with thin film sensors and feedthroughs from INFICON. Engineered for high precision and durability, they enhance process efficiency and film quality.

Reset the filters to get results.

cost effective solution to high-accuracy thickness monitoring for short optical and batch coating processes

- Minimum investment with lowest upfront cost

- Lowest total cost of ownership from extended sensor life

- Maximum throughput with less maintenance

- Easy installation

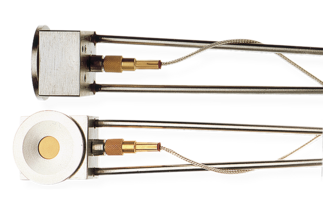

Proven reliability and durability and the best thermal stability of any sensor head on the market.

- Front load crystal holder

- Easy installation

- Available with 2.54 cm (1 inch) bolt feedthrough / CF40 Feedthrough

- Adjustable length if ordererd with compression fittings

proven reliability and durability

- Dual crystals

- Crystal shutter

- Front load crystal holder

- Easy installation

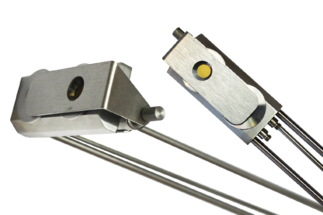

allow crystal installation into the sensor from the side, convenient for systems with insufficient room for front load crystal installation

- No internal cables

- Cool Drawer crystal holder

- Easy installation

- Bakeable if ordered with welded CF40 flange

designed for use in critical processes where it is desirable to have a second crystal in the vacuum chamber

- Dual crystals

- Cool Drawer crystal holder

- No internal cables

- Crystal shutter

simple and inexpensive solution for QCM applications where one crystal may not be enough

- Dual crystals

- Low in price, high in quality

- Front load crystal holder

- Includes crystal shutter

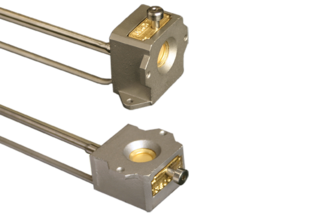

offer proven reliability and durability and have the best thermal stability of any sensor head on the market

- High temperature braze & welded construction

- Bakeout temperatures to 450° C

- Crystal shutter (option)

- Front load crystal holder

repeatability, precision, and durability of quartz crystal microbalance (QCM) measurement to atomic layer deposition (ALD)

- Operating temperature up to 450°C

- Gas purge line keeps back of crystal free of depsotion material

- Welded Conflat flange (CF40) option

- O-ring compression fitting option

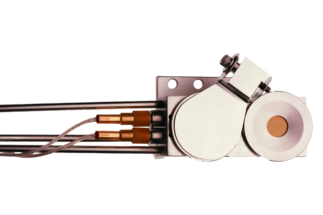

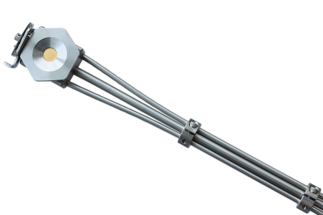

CrystalSix Sensor is critical for long processes demanding continuous rate control

- Holds 6 crystals with robust, automatic switching to maximize process uptime

- Stable crystal temperature, because crystal switching is pneumatically-driven (competitive units use heat-generating motors)

- 1/8" tubes maintain thermal stability and allow flexibility in sensor placement

- Optional crystal shutter available

designed for demanding processes, employing very thick films and several different materials

- Six crystals

- Position feedback (Controller dependent)

- Adjustable length (with optional flange)

- Rugged design

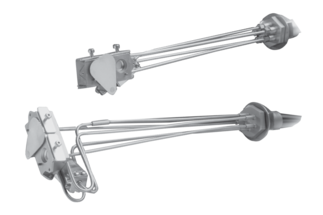

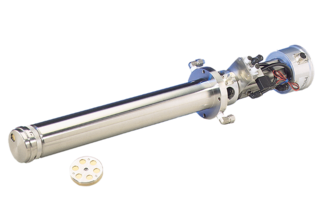

Replaces its crystals automatically without interrupting your process, when partnered with the INFICON IC6 Thin Film Deposition Controller

- Holds 12 crystals with robust, automatic switching to maximize process up-time

- Easy-to-remove carousel allows fast replacement of all 12 crystals

- Stable crystal temperature, because crystal switching is pneumatically-driven (competitive units use heat generating motors)

- Easy-to-remove front deposition shield protects the crystals and carousel from material accumulation, minimizing the need to remove entire sensor for maintenance

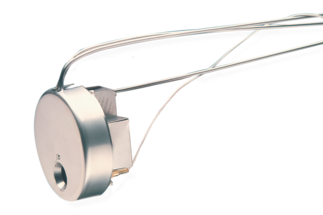

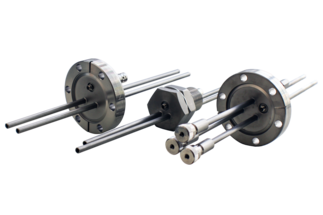

Variety of Quartz Crystal Monitor (QCM) sensor feedthroughs to accommodate many QCM sensor and chamber configurations

- 2.54 cm (1 in.) bolt or CF40 (2.75 in. ConFlat®) styles available

- Available Ultra-Torr O-ring compression fittings

- Custom feedthrough configurations available

- Other feedthrough styles available on request

2.54 cm (1 in.) bolt or CF40 (2.75 in. ConFlat®) styles available, available with bored-through tube fittings

- 2.54 cm (1 in.) bolt or CF40 (2.75 in. ConFlat®) styles available

- Available with bored-through tube fittings