Sensors & Feedthroughs

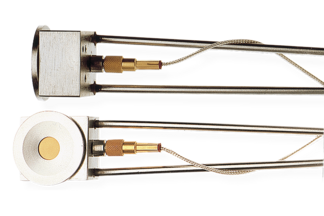

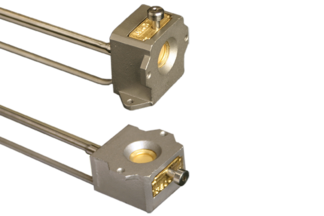

UHV Bakeable Sensor

INFICON UHV Bakeable Crystal Sensors offer proven reliability and durability and have the best thermal stability of any sensor head on the market. Made from 304 Stainless Steel, Molybdenum, Inconel, Nickel, and Alumina materials, the UHV Bakeable Sensor is designed to withstand continuous bakeout temperatures up to 450° C (for bakeout only, water flow required for actual deposition monitoring). The front load design allows for easy insertion of the crystal holder in applications lacking sufficient room for side insertion.

Features

- High temperature braze & welded construction

- Bakeout temperatures to 450° C

- Crystal shutter (option)

- Front load crystal holder

- Easy installation

- CF40 feedthrough

- No brazing or welding to feedthrough required

- Sensor/feedthrough combination welded to customer specified lengths

Specifications

Bakeable Sensor w/ Shutter

Bakeable Sensor w/out Shutter

| Maximum temperature | 400° C continuous (for bake only; water flow recommended for actual deposition monitoring) |

| Crystal exchange | Front loading, self-contained package for ease of exchange. Cam-type locking handle allows easy removal and good thermal contact. Pneumatically operated shutter flips up for easy crystal exchange. |

| Water, air and coax lines | 0.125 in. (3 mm) O.D. water and air x 0.015 in. (0.4 mm) wall thickness seamless 304 stainless steel; 0.188 in. (5 mm) O.D. coax |

| Maximum temperature | 450°C continuous (for bake only; water flow recommended for actual deposition monitoring) |

| Crystal exchange | Front loading, self-contained package for ease of exchange. Cam-type locking handle allows easy removal and good thermal contact. |

| Water, air and coax lines | 0.125 in. (3 mm) O.D. water x 0.015 in. (0.4 mm) wall thickness seamless 304 stainless steel; 0.188 in. (5 mm) O.D. coax |

Accessories

Accessories

Consumables

| Part Number | Description |

| 750-420-G1 | Solenoid Valve, 24V (for use with shuttered and multi-crystal sensors) |

| Name | Description |

| Quartz Monitor Crystals | Quartz Monitor Crystals |

Spare Parts

| Part Number | Description |

| 007-007 | Retainer spring (for crystal holder) |

| 007-064 | Ceramic retainer |

| 007-094 | Clamping spring |

| 007-095 | Handle |

| 007-098 | Female Connector (includes ferrules and nut) |

| 007-099 | Bakeable head contact |

| 007-100 | Insulator for BNC |

| 007-103 | Insulator for bakeable head contact |

| 007-104 | BNC Body |

| 007-147 | #4-40 X 3/8 screw |

| 007-155 | Braze assy - 12 in. (30.5 cm) |

| 007-156 | Braze assy - 20 in (50.8 cm) |

| 007-157 | Braze assy - 30 in. (76.2 cm) |

| 007-228 | #4-40 X 5/8 screw |

| 007-267-P2 | Spreader bar |

| 007-268-P1 | Shoulder washer |

| 007-269-P1 | Shoulder washer |

| 008-007 | CRYSTAL SNATCHER |

| 059-0084 | VCR gasket |

| 070-201 | #4 Split lockwasher |

| 084-069-P1 | #4-40 x 3/16 screw |

| 750-018-P3 | Split clamp |

| 750-018-P5 | Split clamp |

| 750-022-G5 | Bellows assembly - 12 in. (30.5 cm) |

| 750-022-G6 | Bellows assembly - 20 in. (50.8 cm) |

| 750-022-G7 | Bellows assembly - 30 in. (76.2 cm) |

| 750-028-G5 | Braze assy with air line - 12 in. (30.5 cm) |

| 750-028-G6 | Braze assy with air line - 20 in. (50.8 cm) |

| 750-028-G7 | Braze assy with air line - 30 in. (76.2 cm) |

| 750-115-P4 | Coupling (installs onto bellows assembly) |

| 750-118-P4 | Actuator support |

| 750-120-G3 | Shaft assembly |

| 750-216-G1 | Shutter assembly (part of shutter module) |

| 750-218-G1 | Cyrstal holder |

The product is used in the following market