Vacuum Gauges & Controllers

INFICON offers a comprehensive range of vacuum gauges and controllers designed for precise measurement and monitoring of vacuum levels in industrial processes. Our advanced instruments deliver accurate, real-time data, ensuring reliable process control and efficiency across various applications.

Reset the filters to get results.

Medium to Ultra High Vacuum SingleGauge

- Pure Bayard-Alpert measuring system for a wide UHV & HV measurement range

- 2 filaments for Bayard-Alpert system

- Galvanic isolated electronics to avoid electric stray current

- Sliding emission mode to avoid pressure jumps

ATM to Ultra High Vacuum TripleGauge®

- 3 + 1 sensing elements for extremely wide measurement range, cost reduction & space savingness

- 2 filaments for Bayard-Alpert system

- Gas type independent pressure measurement above 10 Torr for reliable load lock control.

- Differential pressure measurement eliminates uncertainty related to atmospheric pressure changes

ATM to Ultra High Vacuum DualGauge

- DualGauge (2 sensing elements) for a wide measurement range, cost reduction & space savingness

- 2 filaments for Bayard-Alpert system

- Pirani interlock protection to avoid premature filament burnout

- Sliding emission mode to avoid pressure jumps

ATM To Medium Vacuum Gauge - High volume standard applications

- Easy push button ATM and HV adjustment

- Space saving rugged design

- Stainless steel measuring cell with metal-sealed feedthrough

- Mounts in any orientation

Most advanced digital Pirani technology, compact size and the variety of features.

- Available with Tungsten (PSG550) or Nickel (PSG552) filament or with a fully ceramic coated (PSG554) sensor unit for highly corrosive applications

- Optional display, setpoints and digital interfaces

- Latest EtherCAT protocol Standard ETG.5003.2080 S (R) V1.3.0

- Easy to exchange plug & play sensor element with on-board calibration data - guarantees high reproducibility and low cost of ownership

Pirani Capacitance Diaphragm Gauge combines Pirani sensor and ceramic capacitance diaphragm sensor in one product

- Gas type independent above 10 mbar

- High accuracy and reproducibility at atmosphere

- Versatile of mounting orientation

- Optional with Nickel (PCG552) filament or with ceramic coated (PCG554) sensor for highly corrosive applications

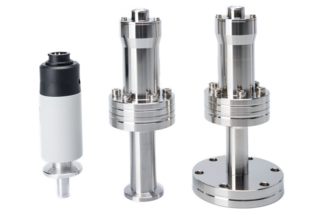

Inverted Magnetron Vacuum Gauge is the workhorse for all vacuum measurement applications. Measurement range from 1x10-9 mbar to atmosphere.

- Long lifetime in harsh environments

- Low magnetic stray field

- Reliable fast ignition

- Fastest maintenance - replaceable insert

Inverted Magnetron Pirani Gauges, measure from 5 x 10-9 mbar to atmosphere

- Combination gauge – Inverted Magnetron & Pirani

- Wide measurement range from 5 x 10-9 mbar to atmosphere

- No filament to burn out

- Excellent ignition properties

Inverted Magnetron Vacuum Gauge is for all ultra high vacuum applications, measurement range from 5x10-11 mbar

- Measurement range down to 5x10-11 mbar

- Extended version, sensor bakeout up to 250°C

- Excellent ignition properties

- Easy to clean

Provide fast real-time leak detection, gas analysis, and process monitoring for semiconductor manufacturing and other markets.

- High speed leak detection allows chamber leak test

- Smart algorithm for easy integration

- Long life time, no filament burns, air inrush protection

- Withstand process chemistry

Single Bayard Alpert sensor, measurement range from 5×10-10 mbar to 2.7×10-2 mbar, Excellent repeatability

- Measurement range from 5×10-10 mbar to 2.7×10-2 mbar (3.75×10-10 Torr to 5×10-2 Torr)

- Excellent repeatability in the process pressure range from 10-8 … 10-2 mbar of 5%

- Overpressure detection protects the filament from premature burnout

- Two long-life yttrium oxide coated iridium filaments

ATM to Ultra High Vacuum hot cathode gauge

Drop in compatible to other manufacturers PBR 260 Pirani/Bayard-Alpert hot cathode gauges

- Partnumber IGG27000 matches

PT R27 000 - Partnumber IGG27001 matches

PT R27 001 - Partnumber IGG27002 matches

PT R27 002

Bayard-Alpert Pirani Combination Gauge, single hot ion filament

- Extremely wide measurement range from 5×10-10 mbar to atmosphere

- Excellent repeatability in the process pressure range

- The Pirani interlock protects the Bayard-Alpert system from premature filament burnout

- Long-life yttrium oxide coated iridium filament

Functions as two gauges in a single compact unit measuring from 5×10-10 mbar to atmosphere.

- Extremely wide measurement range from 5×10-10 mbar to atmosphere

- Two long-life yttrium oxide coated iridium filaments

- Excellent repeatability in the process pressure range

- Pirani interlock protects the filament from premature burnout

Bayard-Alpert Pirani Capacitance Diaphragm Gauge (TripleGauge®), BCG450, combines the advantages of three different technologies in a single, compact, economical package to measure process and base pressure from 5×10-10 to 1500 mbar (3.75×10-10 to 1125 Torr)

- Pirani, Bayard-Alpert and CDG sensors in one gauge

- Gas-type-independent pressure measurement above 10 Torr

- Pirani interlock protects the hot filament from premature burnout

- Automatic Pirani adjustment reduces operator interventions

High Pressure Hot Ionization Pirani Gauge, HPG400, combines High Pressure Hot Ionization and Pirani sensors in a single, compact, economical package to measure pressure from 2×10-6 mbar to atmosphere (1.5×10-6 Torr to atmosphere)

- The high pressure hot ion gauge delivers accurate, reliable pressure measurements from 1×10-5 … 1 mbar

- User selectable hot ion emission activation between 5×10-2 and 1 mbar

- Pirani interlock protects the hot filament from premature burnout

Convection enhanced Pirani technology, compact design, higher accuracy

- Wide measurement range and higher accuracy

- Built-in display, 1 set point relay

- Bright digital LED display

- Analog output signals user selectable

Convection enhanced Pirani technology, with DeviceNet, higher accuracy

- Wide measurement range and higher accuracy near atmosphere

- Digital DeviceNet interface

- Built-in display, 2 set points

- Bright digital OLED display with keypad

Convection enhanced Pirani technology, higher accuracy, OLED display, RS485/RS232

- Wide measurement range and higher accuracy near atmosphere

- All-in-One active gauge with 2 set points,

- 4 analog output signals and 2 digital interfaces

- Bright digital OLED display with keypad

- 4 optional analog output signals

Based on advanced MEMS (Microelctromechanical Systems) sensor technology, Gas type independent above 2 mbar, High accuracy and reproducibility at atmosphere

- Gas type independent above 2 mbar

- High accuracy and reproducibility at atmosphere

- Versatile of mounting orientation

- Selectable analog output signal

Based on advanced MEMS (Microelctromechanical Systems) sensor technology, atmospheric ambient pressure measurement, Gas type independent above 2 mbar

- Gas type independent above 2 mbar

- High accuracy and reproducibility at atmosphere

- Atmospheric ambient pressure measurement

- Up to 3 solid state relays

Single Hot Ion gauge, OLED Display, RS485

- Measurement range from 1.3 × 10-9 to 6.7×10-2 mbar

- Two standard long-life yttrium oxide coated iridium filaments

- Set-point, analog output and RS485

- OLED display with keypad

Big performance, small size

- Excellent span stability – gas type independent

- Alumina sensor

- Compact, smallest size in it's class

- Easy integration, any mounting orientation

Industrial application, temperature compensated

- Full scale ranges from 100 mTorr … 1000 Torr

- Fast stability after power on

- Fast recovery from atmospheric pressure

- Corrosion resistant ceramic sensor

Harsh process application, temperature compensated

- Full scale ranges from 100 mTorr … 1000 Torr

- Fast stability after power on

- Fast recovery from atmospheric pressure

- Corrosion resistant ceramic sensor

Current loop, temperature compensated

- Full scale ranges from 100 mTorr … 1000 Torr

- Fast stability after power on

- Fast recovery from atmospheric pressure

- Corrosion resistant ceramic sensor

Superior signal stability, temperature controlled

- Lower CoO (cost of ownership), 50% faster warm up, energy efficient low power consumption

- Easy integration, wide variety of full scales, flanges and interfaces, standard with two set points

- Easy one push button or remote signal zero command, zero offset adjustable

- Diagnostic port for quick service and maintenance

Superior signal stability, temperature controlled

- Lower CoO (cost of ownership), 50% faster warm up, energy efficient low power consumption

- Easy integration, wide variety of full scales, flanges and interfaces, standard with two set points

- Easy one push button or remote signal zero command, zero offset adjustable

- Diagnostic port for quick service and maintenance

High temperature application, temperature controlled

- Lower CoO (cost of ownership), 50% faster warm up, energy efficient low power consumption

- Easy integration, wide variety of full scales, flanges and interfaces, standard with two set points

- Easy one push button or remote signal zero command, zero offset adjustable

- Diagnostic port for quick service and maintenance

High temperature application, temperature controlled

- Lower CoO (cost of ownership), 50% faster warm up, energy efficient low power consumption

- Easy integration, wide variety of full scales, flanges and interfaces, standard with two set points

- Easy one push button or remote signal zero command, zero offset adjustable

- Diagnostic port for quick service and maintenance

EtherCAT, temperature compensated

- Easy integration, EtherCAT, wide variety of full scales and flanges, standard with two set points

- Easy one push button or remote signal zero command, zero offset adjustable

- Diagnostic port for quick service and maintenance

- Corrosion resistant ceramic sensor

Small footprint, temperature controlled

- Compact, saves valuable tool space

- Easy integration, EtherCAT, wide variety of full scales and flanges, standard with two set points

- Easy one push button or remote signal zero command, zero offset adjustable

- Diagnostic port for quick service and maintenance

Small footprint, temperature controlled

- Compact, saves valuable tool space

- Easy integration, EtherCAT, wide variety of full scales and flanges, standard with two set points

- Easy one push button or remote signal zero command, zero offset adjustable

- Diagnostic port for quick service and maintenance

High speed, temperature controlled

- High productivity – Faster than 2 ms response time (FS > 50 mTorr)

- Flexible integration – EtherCAT fieldbus

- Long lifetime – Proven ceramic sensor

- Forget recalibration – 90 ppm/year full scale stability

High speed, temperature controlled

- High productivity – Faster than 2 ms response time

- Flexible integration – EtherCAT fieldbus

- Long lifetime – Proven ceramic sensor

- Forget recalibration – 90 ppm/year full scale stability

The reference, true high precision

- True high precision pressure measurement – Ceramic technology

- Full stable output – Proven by PTB

- Flexible communication – Various modern interfaces

- All functions integrated – No controller required

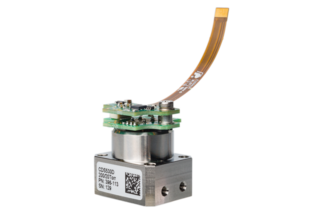

Miniature sensor for OEM

- The miniature sensor offers a high accuracy

- Excellent repeatability and long-term stability

- Weldable feedthrough for custom integration and calibration, or welded custom flange for integration of factory calibrated sensor

Miniature sensor for OEM, dual sensor

- The dual miniature sensor offers a high accuracy in a wide measurement range

- Wide range, high precision

- Excellent repeatability and long-term stability

- Sensor electronics with SPI interface for easy integration

Differential to Ambient - Safety switch for vacuum systems

- Reliable and budget-priced vacuum switch

- High life time

- Rugged design

- Easy to integrate

Absolute pressure switch with a adjustable electrical switching contact

- High switching accuracy (± 0.1 mbar)

- Stable long term operating characteristics

- Rugged, corrosion protected design

- Switching contacts (normally closed) in the reference chamber and thus protected against process media

Absolute Switch - Accurate and reliable pressure detection

- IP 44 protection

- Relay output with potential free contacts

- High-accuracy temperature compensated sensor

- Application pressure range 1×10-9 mbar … 2 bar

Differential Switch - Accurate and reliable pressure detection

- Corrosion resistant all stainless steel design

- Robust design, cleanroom compliant

- Easy installation with setpoints factory preset or field-adjustable

- High-accuracy temperature compensated sensor

Sustainable solution for process measurement, control and data log.

- Simple operation with dot matrix menu guided display for parameter, sensor or general settings

- Very bright and clear Display for long distance Instrument read- out

- Bar graph display with setpoints's or pressure vs. time display

VGC094 is a prestigious solution for vacuum process measurement, control and data log.

- Complete solution for vacuum monitoring and control monitor from 1×10-11 to 1000 mbar, even at long distance

- Bright and clear screen

- Bar graph display with set-point or pressure vs. time views

- Simple sensor operation with intuitive and guided menus for parameter, sensor or general settings

Pirani passive gauge heads for VGC094

- Elastomer (PSG010) or metal-sealed (PSG017, PSG018) design

- Specified high measurement accuracy and repeatability

- Bake-out temperature up to 100 °C (PSG010) / 250 °C (PSG017, PSG018)

- Ionizing radiation resistant up to 106 Gy (PSG017, PSG018)

The Pirani Gauge Enhanced 050 (PGE050) is the passive version of our active convection enhanced Pirani gauges PGE300 and PGE500.

- Convection enhanced Pirani technology for wide measurement range and higher accuracy near atmosphere

- Gold plated tungsten filament

- Mechanical robust and less susceptible to mechanical shock and vibration

- Large choice of flange options

Cold cathode passive gauge heads for VGC094 and VGC083C

- Reliable and proven gauge head design, based on the inverted magnetron principle

- Large vacuum pressure measurement range capability from 1×10-11 (MAG070) to 5×10-3 mbar

- Bakeable to 150 °C (MAG050) or 250 °C (MAG060, MAG070)

- Good ignition properties

The gauge head MAG084 is a unique magnetic field resistant inverted magnetron cold cathode gauge designed to operate with the Vacuum Gauge Controller VGC094.

- Developed to sustain operation in strong external magnetic fields

- Reliable and proven gauge head design, based on the inverted magnetron principle

- Innovative double ionization chamber principle

- Bakeable to 230 °C

Mini hot ion Bayard-Alpert passive gauge head for VGC083

- Long standing, reliable and proven gauge head design

- Drop-in replacement thanks to its compact size, large choice of connection flanges and fittings

- Dual yttrium oxide coated iridium filament cathode assembly

- Electron bombardment (EB) degassing

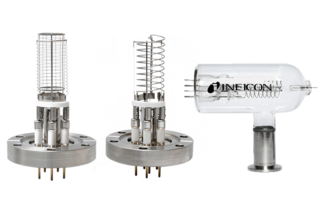

Bayard-Alpert passive gauge heads for VGC083

- Long standing, reliable and proven gauge head design

- Drop-in replacement for most nude hot ion gauge heads

- Wide range of emission currents (100 μA to 10 mA)

- Available with single/dual yttrium oxide coated iridium and dual tungsten filament cathode assemblies

Hot cathode ionization passive gauge heads for IM540

- High accuracy of the measurements due to individually calibrated sensing system

- Exchangeable cathode

- Extreme high temperature bake-out up to 400 °C

The new standard of ionization vacuum gauge.

- Developed for applications requiring high measurement accuracy in the high and ultra-high vacuum range

- Electrode system configuration according to ISO/TS 6737

- True pressure for all gas species thanks to predictable relative gas sensitivity with small uncertainty

Advanced controller for process measurement and data recording.

- Easy-to-use dot matrix menu interface for adjusting parameters, sensors or general settings

- Clearly visible and bright display for remote reading of device data

- Bar graph for visualizing setpoints or displaying pressure over time

Cost effective pressure monitoring solution.

- User selectable measurement unit (Pa, mbar or Torr)

- Compact bench top model design can be easily mounted in a panel or 19" rack

- 0 to 10 V output signal from the gauge is available for use in PLC or with a chart recorder

- One free adjustable set point

Three channel controller for passive gauges

- Flexible solution for vacuum pressure monitoring and controlling from atmosphere down to ultra-high vacuum

- Clear and simple operation with three individual bright LED displays

- Parameter, sensor and general settings with softkeys

The Ion Reference gauge Controller IRC081 and its user interface are an operating and display interface to the standardized Ion Reference Gauge IRG080.

- Operating and display solution for accurate vacuum pressure measurement

- User control on all IRG080 gauge parameters set

- Simple manual operation with 5 potentiometers

- User Interface connection via USB-B port to PC

Single channel controller for PGE050

- Display`s and control wide measurement range from 1.3×10-4 up to 1333 mbar

- Bright digital OLED display with keypad for simple set up and Operation

- 4 user selectable analog output signals, 2 set point relays

- RS232/RS485 digital Interface

Versatile hot cathode ionization passive gauge controller

- Supports the operation of the IE414 (Bayard-Alpert) and the IE514 (extractor) hot cathode ionization gauges

- Two active gauges from the PSG5xx (Pirani), PCG55x (Pirani-Capacitance diaphragm) and CDG (Capacitance diaphragm) active gauge lines can be connected and operated

- Simple operation with menu guided display for parameter, sensor or general settings

Connect to INFICON CDG product line to provide a 4 Digit Display

- 4 Digit display for easy read out

- Large 10mm active LED display -

readable from distance and wide range gauge of angle - In-line plug design

- 15pin D-Sub, no extra power connection

Reliable, High-Performance Vacuum Gauges for Industrial Processes

INFICON offers high-performance solutions for industrial vacuum monitoring with its comprehensive range of vacuum gauges, pressure gauges and vacuum sensors. Our instruments ensure accurate measurement of vacuum levels in industrial processes and provide real-time data through digital vacuum monitoring.

Our products offer high stability, reliable measurements for critical processes, reduced system downtime and improved operational efficiency.

With INFICON vacuum technology, industries can maintain optimal performance and ensure high-quality results in vacuum-dependent processes. We ensure minimal downtime when switching from competitor's vacuum gauges to INFICON by offering seamless integration and customized installation support, allowing for a smooth transition without disrupting critical processes.