製品・サービスについての詳細はこちら

Related webinars

Intelligent solution for real-time vacuum gas monitoring

In this webinar we will discuss some common applications in the optical, OLED, and solar industry. We will unpack a list of unique key features exclusively offered by INFICON that are tailored to your application

A Basic Guide to Capacitive Vacuum Gauges

QCM use in the semiconductor industry for processes like ALD, E-beam, resistive source and sputtering.

Quartz crystal microbalance (QCM) technology has been used for decades to control deposition rate and thickness for the most complex processes seen in the ophthalmic, optical, display, and solar markets. INFICON has recently made a new advancement in QCM technology to address a problem seen across all of these industries related to QCM temperature effects. Thermal shock can cause QCM thickness errors which can decrease yield and increase manufacturing costs if temperature is not accounted for correctly.

Temperature impacts the frequency measurement and can create false mass readings. Thin film deposition controllers currently on the market have no good way of distinguishing frequency shifts related to mass from frequency shifts related to temperature, resulting in thickness errors and poor PID control. This can be detrimental to complex coating processes due to the low deposition rates and incredibly thin layers required. Thermal shocks can occur at any point in a deposition process and can cause unnecessary PID-loop corrections, triggering non-uniform deposition in respect to time. This means that the quality throughout the bulk of the material is inadequate. For very thin films, the thickness termination may not be at the real intended thickness because the process time window is small compared to the time allowed for a QCM to recover from a thermal shock event.

INFICON has patented a new temperature compensation technique for SC-cut crystals to remove the effects of temperature variation on the QCM without the need for additional hardware or custom and expensive sensors.

Please join us for the ‘Temperature Compensation for QCMs’ webinar, hosted by Sheldon Wayman, Product Engineer for INFICON Inc.

Smart essentials for intelligent leak detection

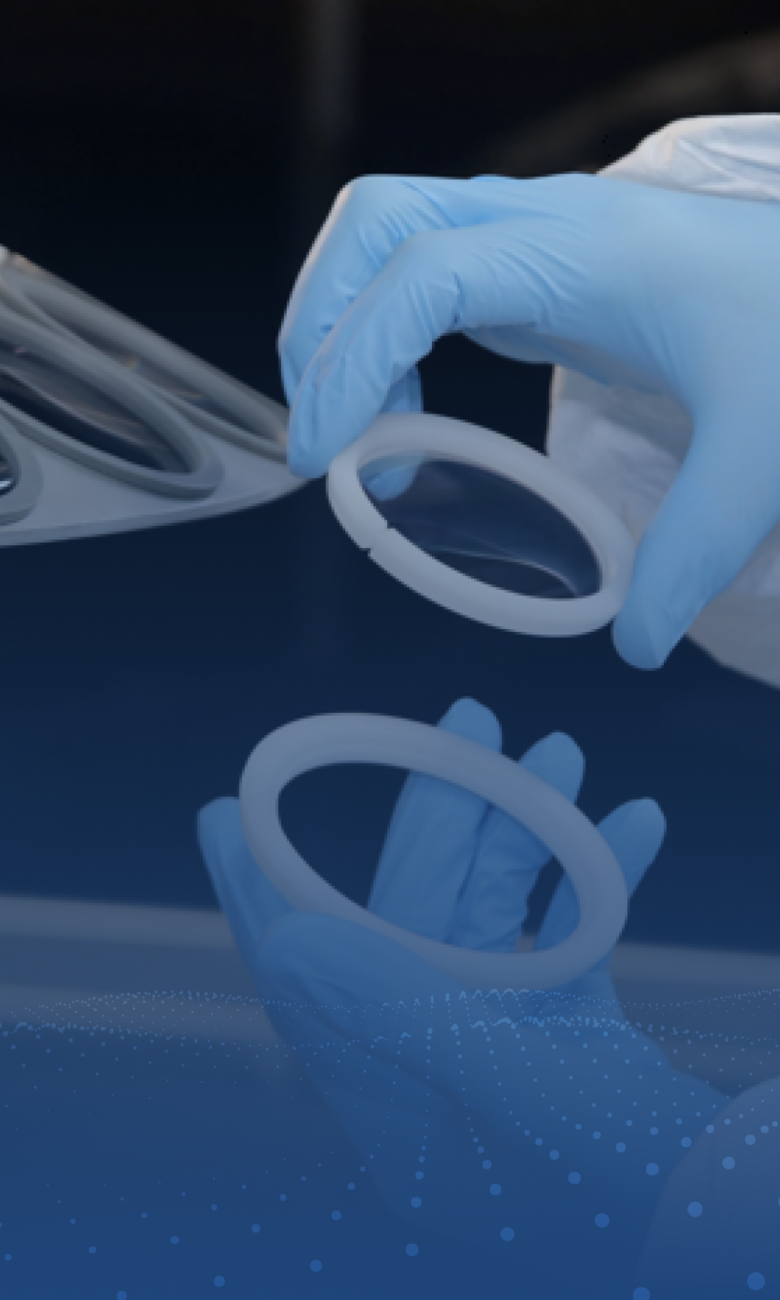

CrystalSix and Crystal 12 are rotary Quartz Crystal Monitors utilized in OLED, Solar and Semiconductor applications, to name a few. QCMs like these also sometimes require user troubleshooting and maintenance to ensure good connectivity as well as crystal positioning within the aperture. During this webinar you will learn about the CrystalSix and Crystal12 and best practices to troubleshoot and maintain them.

A new future proof Hot Ion Gauge generation from INFICON

Deep dive into the capabilities of Cold Cathode gauges